Introduction to RC Propeller Motors

A propeller is a device with a rotating hub and radiating blades that create thrust when rotated through a fluid. This guide is for RC hobbyists, boaters, and anyone interested in maximizing the performance of their remote control craft. Choosing the right propeller motor is essential for achieving optimal speed, efficiency, and handling in your RC craft.

Propeller motor technology plays a crucial role in getting the best performance from your remote control aircraft and boats. At Retek Motion, we offer a wide selection of propeller motors tailored to various needs, backed by years of engineering to enhance efficiency and power.

Brushless motors are popular among RC enthusiasts because they deliver higher efficiency and more reliable performance compared to traditional motors.

When choosing a propeller motor, it’s essential to consider factors like pitch, thrust, and how well the motor matches your boat’s specs. The propeller design also influences acceleration and overall handling.

Expert advice from Retek Motion can help you find the right propeller motor for your setup, ensuring you get the best balance of performance and efficiency.

Propeller Motor Types

Propeller motors are primarily categorized by their internal drive mechanism and physical configuration, each suited to specific project goals like speed, lifting power, or budget. They are broadly divided into Brushed and Brushless types, with the latter further split into Inrunners and Outrunners.

- Brushed Motors: These use carbon brushes to transfer electricity to the motor windings. They are generally more affordable and easier to maintain, but have a shorter lifespan and lower efficiency.

- Brushless Motors: These do not use brushes and are more efficient, reliable, and longer-lasting. Brushless motors are further divided into:

- Inrunner Motors: The rotor spins inside the stator. These are typically used for high-speed applications.

- Outrunner Motors: The rotor spins on the outside of the stator, providing more torque at lower speeds, making them ideal for applications requiring more lifting power.

Electric motor options include brushless motors, known for their efficiency and reliability, making them ideal for RC craft. Propeller motors come in various internal drive mechanisms and physical configurations, each suited for specific units and uses.

You’ll find both brushed and brushless motors suitable for applications like drones, boats, and aircraft. Propeller types vary too—from fixed-pitch to controllable-pitch and constant-speed, made from materials like wood, aluminum, or composite—all affecting performance, cost, and maintenance.

Consider the power, speed, and efficiency each motor type offers to pick the best fit for your RC craft.

Also, think about maintenance requirements and how easily you can upgrade or repair your motor.

Propeller Design

The blades of a propeller motor push air or water backward, creating thrust based on Newton’s Third Law. This produces a pressure difference—lower pressure in front of the blades and higher pressure behind—resulting in forward motion through aerodynamic lift (Bernoulli’s Principle).

- The design of your propeller greatly affects your RC craft’s performance. Pitch, blade angle, and material all influence efficiency and speed. High-quality materials provide durability and consistent results. Blades are twisted from hub to tip to maintain a uniform angle of attack.

Blade Count and Stability

- A three-blade propeller often offers better stability and performance, especially for water sports and cruising. The blade surface design can reduce slip, improving lift, efficiency, and fuel economy.

Cavitation and Performance Loss

- The ideal propeller depends on your craft’s type and intended use. Cavitation—vapor bubbles forming on blade surfaces due to low pressure—can cause performance loss and damage.

- I’ve seen this fail when the propeller design didn’t match the craft’s requirements, so consulting experts or doing proper research is always a smart move.

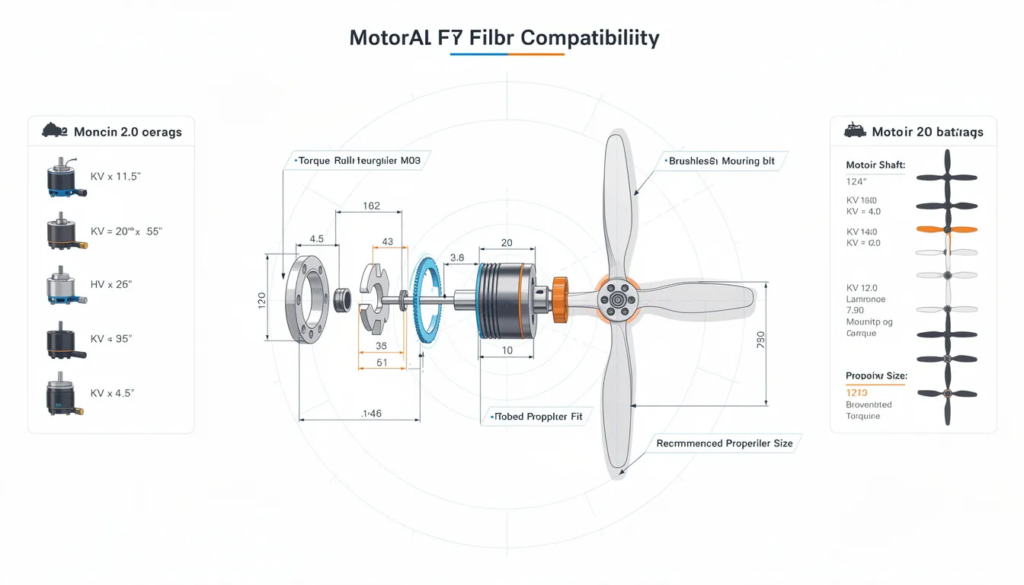

Motor and Propeller Compatibility

- Matching your motor and propeller is key to optimal performance and efficiency. Make sure the propeller fits your motor and meets the engine’s specifications.

- Pay attention to shaft size, pitch, and thrust when selecting a propeller motor. For example, Solas Rubex Hub Kits work with several propeller systems, including Michigan Wheel and Mercury Flo Torq. Turning Point Hub Kits are also compatible with multiple systems, like Mercury Flo-Torq II and Michigan Wheel XHS.

- There’s a wide selection of propeller motors available to suit different needs. The propeller must match the engine’s power output and specs to avoid damage and ensure smooth operation.

- Think about the control and handling you want, plus any potential upgrades or modifications.

High-Performance Brushless Motors for Propellers

- High-performance propeller motors deliver top speed and efficiency, making them perfect for racing and competitive use.

- These motors use advanced materials and precise engineering. Aluminum propellers are lightweight and affordable, ideal for general use. Stainless steel props offer better strength, durability, and resistance to underwater impacts.

Mercury Black Max propellers are well-balanced aluminum props suitable for engines under 250 HP. Mercury’s Modern lineup includes premium stainless steel props for a range of boating experiences.

- BackwaterInc.c provides a broad selection of stainless steel and weedless mud motor propellers.

- Keep in mind that high-performance motors can be heavier and more expensive. Proper maintenance reduces vibration and extends motor life, ensuring smooth operation.

Propeller Motor Maintenance

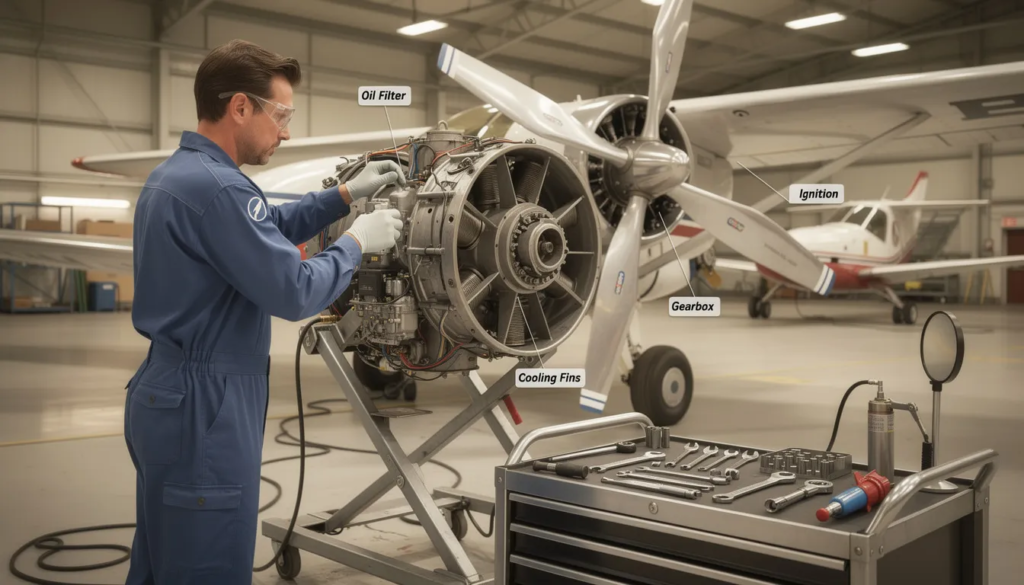

Regular maintenance is essential to keep your propeller motor running efficiently. This includes:

- Cleaning the motor and propeller

- Lubricating moving parts

- Replacing worn or damaged parts like propellers, shear pins, rubber bushings, and drive sleeves promptly to prevent bigger problems

Skipping maintenance can lower efficiency and increase wear, risking damage to the engine or transmission.

Brushed motors use carbon brushes and typically last 1,000–5,000 hours, making them budget-friendly. Brushless motors last much longer (10,000+ hours) but require more complex electronic controllers.

Maintenance costs and repair options vary, so factor those into your decision when choosing a motor.

Choosing the Right Propeller Motor

Selecting the right propeller motor for your RC craft requires careful consideration of performance, efficiency, and compatibility. Common choices depend on material, pitch, and how well the motor matches your craft.

Below is a summary comparison of propeller motor and propeller types by performance, efficiency, cost, and maintenance:

| Type | Performance | Efficiency | Cost | Maintenance |

|---|---|---|---|---|

| Brushed Motor | Moderate | Lower | Low | Simple, more frequent |

| Brushless Motor | High | High | Higher | Less frequent, more complex |

| Inrunner | High speed | High | Higher | Moderate |

| Outrunner | High torque | High | Higher | Moderate |

| Fixed-Pitch Prop | Simple, reliable | Good | Low | Minimal |

| Controllable-Pitch | Adjustable, versatile | High | Higher | More complex |

| Constant-Speed | Optimal at all speeds | Very high | Highest | Most complex |

| Material: Wood | Lightweight, less durable | Moderate | Low | Occasional |

| Material: Aluminum | Durable, affordable | Good | Moderate | Minimal |

| Material: Composite | Lightweight, strong | High | Higher | Minimal |

Expert advice or thorough research can help you make the best choice. Stores like Retek Motion offer a wide selection and knowledgeable support to guide your purchase.

Consider how much customization and flexibility you need, along with upgrade options.

Also, think about cost, value, and return policies. When you find the right propeller motor, you can be confident it will meet your needs.

Propeller Motor Accessories

Essential Accessories

Having the right accessories can significantly improve your boat or aircraft’s performance. This includes marine propellers, boat motors, and electric motors designed for top efficiency. Whether you prefer a brushless motor or a traditional engine, choosing the ideal propeller is key to achieving top speed and better handling.

For water sports, a three-blade propeller often provides the power and control needed for towing and cruising. You also need to consider your craft’s engine type, shaft, and thrust requirements. Expert advice from Retek Motion can help you find the right prop and blades for smooth, efficient operation.

Choosing the Right ESC

Besides propellers, electronic speed controllers (ESCs) are essential for regulating your electric motor’s speed and efficiency. A good ESC can make a noticeable difference in performance and motor life. The material and build of your propeller—whether aluminum or stainless steel—also affect durability and wear resistance.

Buying Tips

When shopping for accessories, look for stores offering a wide selection, fair prices, and excellent customer service. Buying from a reputable dealer like Retek Motion ensures secure delivery, easy returns, and expert tips.

Investing in the right accessories will enhance your craft’s performance and enjoyment. Whether you’re experienced or just starting out, the right gear makes a real difference in your time on the water or in the air.

Installation and Setup

Proper installation and setup are crucial for your propeller motor to perform at its best. Follow manufacturer instructions carefully or get expert help to install your motor and components safely.

Prop nuts come in different sizes for various shaft types, such as:

- 3/4-10

- 3/4-16

to ensure a secure fit.

Installation can be tricky, so consider the complexity and potential for mistakes. Also, factor in the cost of installation services and whether warranties or guarantees apply.

When ordering parts or kits, check shipping options and delivery times to avoid delays. Here’s what actually worked for many users: taking time to double-check compatibility and fit before final installation saves headaches later.