You start a drone motor by sending a signal from your remote controller, which travels through the flight controller and reaches the ESC. The ESC then provides precise power from the battery to the motor, allowing it to spin. High-performance ESCs play a crucial role in this process, as seen in the rapidly growing global ESC market. The integration of ESCs with motors, flight controllers, and batteries ensures efficient, reliable startup and operation for modern drones.

Key Takeaways

- Start your drone motor by sending commands from the remote controller through the flight controller and ESC to the motor.

- Each component—remote controller, flight controller, ESC, battery, and motor—has a unique role in ensuring smooth motor startup.

- Always power on the remote controller before the drone to establish a reliable connection and prevent startup issues.

- Arm the motors safely by following proper procedures and checking that the throttle is at its lowest position.

- The ESC energizes motor coils in a timed sequence, then uses back-EMF feedback to control motor speed smoothly and efficiently.

- Perform regular pre-flight checks, including inspecting propellers, battery health, and connections to avoid startup failures.

- Keep your ESC firmware updated and calibrate ESCs when needed to ensure accurate motor control and responsiveness.

- If you face startup problems, check for physical resistance, signal issues, power supply problems, or ESC and motor faults promptly.

Drone Motor Components

Motor

The motor is the heart of your drone’s propulsion system. When you start your drone, the motor converts electrical energy into mechanical rotation, spinning the propellers and generating lift. You need to choose a motor that matches your drone’s size and performance needs. Here are some important technical specifications and performance factors to consider:

- KV Rating: This tells you how fast the motor spins per volt. A higher KV means more speed but less efficiency and more current draw.

- Torque: This is the force that helps the motor spin the propellers. Larger stators and more magnets usually mean higher torque.

- Efficiency: Measured as grams of thrust per watt, efficiency affects how long your drone can fly.

- Current Draw: This shows how much power the motor uses. Higher current draw means you need a stronger ESC and battery.

- No-load Current and Voltage: These values help you estimate the motor’s internal resistance and quality.

- Maximum Current and Power Ratings: These limits protect your motor from overheating or damage.

- Propeller Compatibility: The right propeller size and pitch will help you get the best performance from your motor.

- Weight and Size: Heavier motors can reduce flight time, while larger motors can handle bigger propellers.

Tip: Always match your motor’s specifications to your drone’s design for the best balance of speed, efficiency, and flight time.

ESC

The Electronic Speed Controller (ESC) acts as the bridge between your flight controller and the motor. When you send a command to start the drone, the ESC receives a signal from the flight controller and delivers the right amount of power from the battery to the motor. The ESC converts the battery’s DC voltage into three-phase AC current, which is what brushless motors need to spin.

| ESC Model | Continuous Current Rating | Voltage Rating | Firmware Type | Key Reliability Features |

|---|---|---|---|---|

| MEPS SZ60A 6S 4-in-1 | 60A | Up to 6S | BLHeli_32 | High-quality MOSFETs, sturdy heatsink, efficient cooling |

| SpeedyBee BLHeli_S 55A | 55A | 4S and 6S | BLHeli_S | Reliable performance, stable under high current |

| T-Hobby F55A ProII 6S | 55A | Up to 6S | AM32 | Faster response, smoother throttle, built-in BEC, aluminum heatsink |

You should always check the ESC’s current and voltage ratings to make sure they match your motor and battery. Advanced ESCs use firmware like BLHeli or AM32 for smoother control and faster response. Built-in safety features, such as overcurrent and over-temperature protection, help prevent damage. Communication protocols like PWM, OneShot, and DShot allow for quick, reliable signals and real-time feedback, which keeps your drone stable and responsive.

Flight Controller

The flight controller is the brain of your drone. It processes your commands and sensor data, then sends precise instructions to each ESC. When you start the drone motor, the flight controller coordinates the timing and speed of all motors to keep your drone balanced and stable.

- The flight controller uses algorithms like trapezoidal control and field-oriented control (FOC) to manage motor speed.

- FOC can detect rotor angles with an accuracy of 1° to 5°, which helps deliver maximum torque.

- Most drone motors spin at speeds over 12,000 RPM, and the flight controller ensures each motor runs at the right speed for stable flight.

- PID controllers inside the flight controller constantly adjust motor speeds to correct for changes in wind or movement.

- The flight controller communicates with the ESCs to make real-time adjustments, ensuring smooth takeoff and flight.

Note: A well-tuned flight controller makes your drone easier to fly and more responsive to your commands.

Battery

The battery supplies the electrical energy that powers every component in your drone, including the drone motor. When you start your drone, the battery delivers a surge of current to the ESC, which then distributes power to the motors. You need a battery with the right voltage and capacity to ensure reliable startup and sustained flight. Lithium Polymer (LiPo) batteries are the most common choice because they offer high energy density and fast discharge rates.

Battery performance directly affects how well your drone motor starts and operates. If your battery cannot provide enough current, you may experience weak motor spin-up or even startup failure. Modern drones use advanced battery management systems to monitor voltage, current, and temperature. These systems help prevent over-discharge and overheating, which can damage both the battery and the drone motor.

Recent research highlights the importance of accurate battery health prediction for drone reliability. The following table summarizes findings from real-world drone battery data:

| Metric / Model Aspect | Quantitative Result / Observation |

|---|---|

| Prediction accuracy improvement | Hybrid probabilistic CNN model shows 14.8% better probabilistic accuracy over simpler Quantile Linear Regression (QLR) model. |

| Comparative improvements | QRF and QGB models show 37.8% and 32.3% improvements respectively over QLR in battery discharge voltage prediction. |

| Uncertainty metrics affected by dropout rate | Calibration improved from 0.06 to 0.29; Sharpness from 0.05 to 0.23; CRPS from 0.0178 to 0.0561 with dropout rate increase from 0.01 to 0.2. |

| Model complexity vs accuracy | QLR (12 parameters) is computationally efficient but less accurate; MC dropout CNN (4912 parameters) is more accurate but computationally expensive. |

| Epistemic uncertainty | Increases with dropout rate, indicating model uncertainty trade-offs. |

| Dataset and evaluation context | Real operational drone battery data under varying load conditions from inspection drones used for offshore wind turbine missions. |

These results show that better battery health prediction leads to more reliable drone operation. You can expect fewer unexpected shutdowns and more consistent motor performance when you use batteries with advanced monitoring and prediction features.

Tip: Always check your battery’s voltage and health before each flight. Replace batteries that show signs of swelling, overheating, or rapid voltage drops.

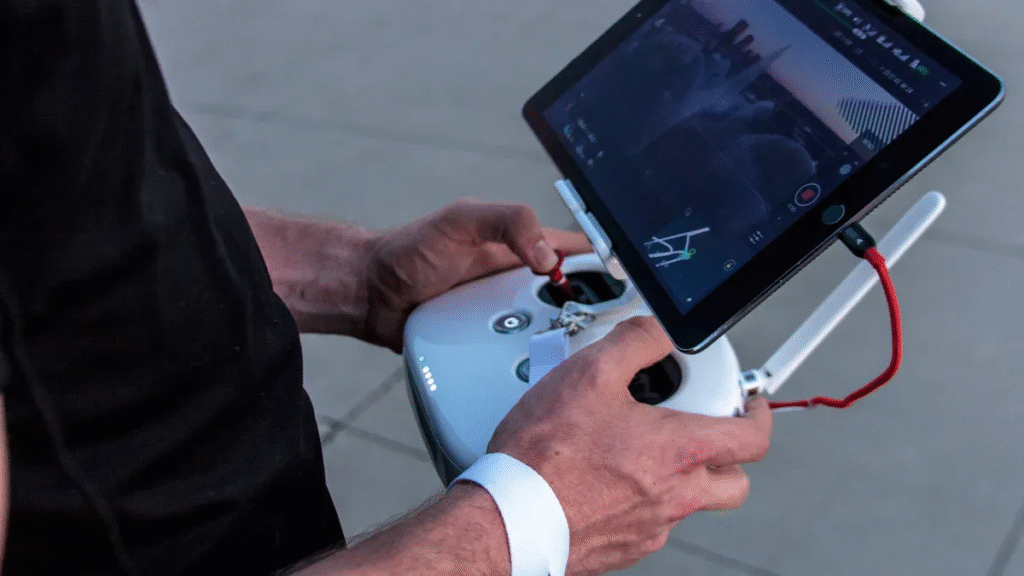

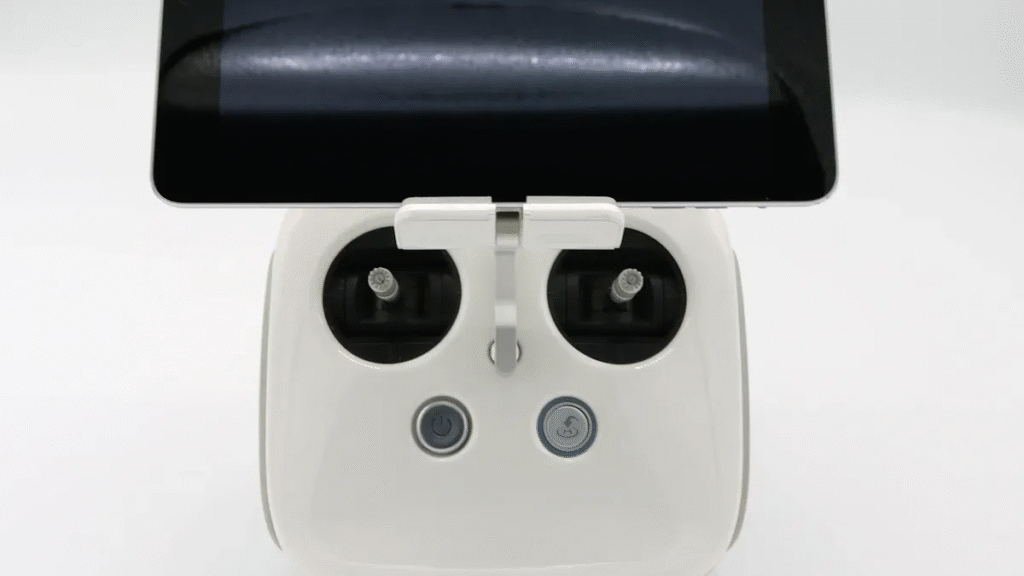

Remote Controller

The remote controller acts as your direct link to the drone. You use it to send commands that start the drone motor and control flight. The remote controller transmits signals to the flight controller, which then relays instructions to the ESC and motors. Without a reliable remote controller, you cannot safely start or operate your drone.

Key points about the remote controller’s role in starting the drone motor:

- The remote controller continuously sends control signals, known as Virtual Stick Commands, to your drone.

- These signals are essential for both startup and in-flight maneuvers, such as waypoint navigation.

- Reliable and constant communication ensures your drone responds instantly to your commands.

Best practices for using the remote controller:

- Power on the remote controller before turning on your drone. This sequence ensures the uplink connection is active, allowing the drone to receive startup and control signals.

- Some drone models may start regardless of the power sequence, but powering the remote controller first is the recommended best practice.

- Proper antenna placement on both the remote controller and the drone is crucial for maintaining strong RF signals.

- Environmental factors like electromagnetic interference, frequency congestion, and physical barriers can weaken signal quality.

- Maintaining a clear line of sight and avoiding signal null points will improve the reliability of your communication.

Note: Always perform a quick range and signal check before each flight. This step helps prevent loss of control during critical moments, especially during takeoff and landing.

Starting Process

Pilot Input

You begin the startup sequence by sending a command from your remote controller. This action acts as the first link in the chain that brings your drone to life. When you move the throttle stick or press the arming switch, you instruct the system to prepare for flight. The remote controller transmits your input as a digital signal, ensuring accuracy and speed.

Tip: Always check that your remote controller is powered on and properly bound to your drone before sending any commands. This step prevents accidental motor spin-up and ensures a safe startup.

Signal to Flight Controller

Your command travels instantly to the flight controller. This device serves as the central processor for all incoming signals. It interprets your input, checks the drone’s status, and determines if conditions are safe for motor activation. The flight controller uses advanced algorithms to process your request, including safety checks for arming status, throttle position, and sensor feedback.

The flight controller then prepares a precise command for the next stage. It selects the correct protocol, such as DShot, to communicate with the ESC. DShot protocols offer configurable update rates, ranging from 800Hz to 4kHz. These high frequencies ensure that your commands reach the ESC quickly and reliably. Built-in checksum protection verifies the integrity of each command, reducing the risk of errors during startup. The system also resists timing mismatches between the flight controller and ESC, which keeps the startup process smooth and consistent.

Command to ESC

Once the flight controller processes your input, it sends a digital command to the ESC. The ESC receives this command and prepares to deliver power to the drone motor. You benefit from the reliability of modern ESC protocols, which support features like motor direction reversal and real-time feedback. The ESC’s firmware interprets the command, checks for safety conditions, and then initiates the motor startup sequence.

The ESC can use different startup algorithms, such as STOPLL/Cordic or HSO, depending on your configuration. For HSO startup, you may select initial angle estimation methods like RsDC estimation, pole pulse, or manual mode. These options help the ESC determine the correct timing for energizing the motor coils, especially during sensorless startup. The ESC then enables the motor, and you see the motor begin to spin up. Throughout this process, the ESC updates its status and communicates any issues back to the flight controller, ensuring you stay informed.

Note: Proper configuration of the ESC and flight controller ensures that your drone motor starts efficiently and safely every time.

ESC to Motor

When your ESC receives the command, it begins the process of energizing the motor coils. The ESC rapidly switches power to the three phases of the brushless motor, creating a rotating magnetic field. This field interacts with the permanent magnets inside the motor, causing the rotor to turn. You benefit from precise timing adjustments during this stage. The ESC can advance or retard the timing to match the speed and load of the motor.

Sensor and timing studies show that fixed timing in ESCs can lead to current phase misalignment with the back electromotive force (back EMF) at high speeds. This misalignment increases losses and reduces efficiency because current flows through the MOSFET body diodes instead of the FETs. By adjusting the timing, the ESC aligns the current and voltage phases more closely. This improves the conversion of electrical energy into mechanical rotation and reduces heat buildup.

Tip: Proper ESC timing not only boosts performance but also extends the life of your drone motor by minimizing unnecessary heat and electrical losses.

You can see the effects of timing adjustments in several ways:

- Advancing or retarding timing changes the motor’s RPM, heat output, and power.

- An optimal timing advance, such as 3 degrees for some motors, increases RPM without causing overheating.

- Torque feedback can help adjust timing dynamically, though most hobby ESCs do not use this feature.

- Field weakening through phase advance lets the motor run faster and more efficiently at high speeds.

- Even with perfect timing, the maximum power depends on the strength of the motor’s electromagnetic coils.

The ESC’s ability to manage these factors ensures a smooth and efficient transition from electrical signal to mechanical motion.

Motor Spin-Up

Once the ESC energizes the coils, the drone motor begins to spin. At startup, the ESC uses a sensorless method, sending a series of timed pulses to the motor. These pulses create the initial rotation. As the motor gains speed, the ESC starts to detect the back EMF generated by the spinning rotor. This feedback allows the ESC to synchronize its switching with the actual position of the rotor, making the spin-up process smoother and more reliable.

Modern systems often use closed-loop control, where the ESC or flight controller receives real-time feedback about the motor’s speed and position. This feedback lets the system compare the actual speed to the target speed and make quick adjustments. You get precise control, even if the load on the motor changes suddenly. Alarm signals can alert you to problems like motor lock or overload, increasing reliability and safety.

- Closed-loop control with real-time speed feedback improves accuracy from -5% to ±1% at 1000 RPM.

- Acceleration and deceleration settings help the motor start and stop smoothly.

- Instantaneous stop and bi-directional operation give you flexible and reliable control.

Note: Reliable motor spin-up depends on both the ESC’s timing and the feedback system. If you notice slow or uneven startup, check your ESC settings and ensure your feedback systems are working correctly.

A well-tuned ESC and feedback system ensure your drone motor spins up quickly, efficiently, and safely every time you start your drone.

Drone Motor Startup Sequence

Power On

You begin the startup sequence by powering on your drone. This step activates the entire electronic system, including the flight controller, ESCs, and sensors. When you connect the battery, the system performs a quick self-check. The flight controller and ESCs initialize their firmware and prepare for communication. You may hear a series of beeps from the ESCs. These tones indicate that the ESCs have received power and are ready to receive commands.

Technical documentation describes how the motor control system uses a microcontroller to manage the initial power-up. The microcontroller checks the status of all components and waits for further instructions. At this stage, the system does not know the exact position of the motor’s rotor. The lack of initial rotor position information means the motor cannot immediately start spinning in the correct direction. The system must wait for additional input before it can proceed.

Tip: Always make sure your battery is fully charged and securely connected before powering on your drone. This step helps prevent voltage drops and startup failures.

Arming

After you power on the drone, you must arm the motors. Arming acts as a safety feature that prevents accidental motor spin-up. You usually arm the motors by moving the throttle stick to a specific position or by flipping a dedicated switch on your remote controller. The flight controller receives your arming command and checks several safety conditions. It verifies that the throttle is at its lowest position, the battery voltage is within a safe range, and all sensors are functioning correctly.

Once the system confirms these conditions, the flight controller sends an arming signal to the ESCs. The ESCs then prepare to energize the motor windings. During this phase, the ESCs may perform additional checks, such as verifying the integrity of the signal from the flight controller and confirming that no faults exist in the power system. The arming process ensures that your drone will not start unexpectedly and that all systems are ready for controlled startup.

Note: Never attempt to arm your drone indoors or in a crowded area. Always follow safety guidelines to protect yourself and others.

Throttle Input

With the motors armed, you can now provide throttle input. You do this by moving the throttle stick on your remote controller. The flight controller receives your input and translates it into a command for the ESCs. The ESCs then begin the process of energizing the motor windings in a specific sequence. At this point, the system still lacks precise information about the rotor’s position.

Technical documentation explains that, during initial startup, the ESCs use a predefined sequence of timed commutations. The ESCs switch power to the motor windings based on estimated rotor positions. This method may cause the motor to rotate partially in the wrong direction until the system receives feedback from sensors or detects the correct rotor position. The ESCs monitor the voltage and current waveforms, looking for signals that indicate the rotor’s movement. Once the system detects reliable feedback, it adjusts the commutation timing to match the actual rotor position. This transition marks the shift from open-loop startup to closed-loop control, where the ESCs use real-time feedback to optimize motor performance.

Tip: Apply throttle smoothly and avoid sudden increases. Gradual throttle input helps the ESCs synchronize with the motor and ensures a stable startup.

Timed Commutations

When you start your drone, the ESC cannot detect the rotor’s position right away. To solve this, the ESC uses a method called timed commutations. This process sends a series of electrical pulses to the motor windings in a fixed sequence. These pulses create a rotating magnetic field that tries to turn the rotor. You can think of this as giving the motor a gentle push to get it moving.

During this stage, the ESC does not rely on feedback from the motor. Instead, it estimates where the rotor should be and energizes the coils in a timed pattern. The ESC increases the frequency of these pulses step by step. This gradual increase helps the rotor gain speed without stalling or moving in the wrong direction.

Here is how the timed commutation process works:

- The ESC sends a pulse to one set of windings.

- The rotor starts to move slightly.

- The ESC quickly switches to the next set of windings.

- The process repeats, creating a rotating field.

- The rotor follows this field and begins to spin faster.

Tip: If you hear a clicking or chattering sound during startup, the ESC may be struggling to synchronize with the rotor. This often means the timed commutations are not strong enough or the battery voltage is too low.

You should know that the timed commutation phase is short. Once the rotor reaches a certain speed, the ESC can switch to a more advanced control method that uses real feedback.

Back-EMF Detection

As the rotor spins faster, it generates a voltage called back electromotive force (back-EMF). This voltage appears in the motor windings when the magnetic field from the spinning rotor cuts through the coils. The ESC monitors this back-EMF to figure out the exact position of the rotor.

When the ESC detects a strong enough back-EMF signal, it switches from timed commutations to sensorless control. Now, the ESC uses the back-EMF to time its pulses perfectly with the rotor’s position. This change allows the motor to run smoothly and efficiently.

You benefit from back-EMF detection in several ways:

- The ESC can adjust timing in real time, which improves efficiency.

- The motor responds faster to throttle changes.

- The system reduces heat and power loss.

- You get more reliable startup and smoother acceleration.

| Startup Phase | Control Method | Feedback Used | Main Benefit |

|---|---|---|---|

| Timed Commutations | Open-loop (estimated) | None | Initial rotor movement |

| Back-EMF Detection | Closed-loop (sensorless) | Back-EMF signals | Smooth, efficient operation |

Note: If your ESC cannot detect back-EMF, the motor may fail to start or run roughly. Always check your ESC settings and wiring if you notice startup problems.

By understanding these two phases, you can better troubleshoot issues and optimize your drone’s performance.

ESC Role

Signal Processing

You rely on the ESC to act as the interpreter between your flight controller and the motor. The ESC receives digital signals that tell it how fast and in which direction to spin the motor. Inside the ESC, a microprocessor serves as the control center. This microprocessor reads your input, checks for errors, and translates your commands into precise instructions for the motor.

The ESC uses advanced communication protocols like DShot or PWM to ensure your commands reach the motor quickly and accurately. These protocols help reduce signal lag and prevent miscommunication. The microprocessor constantly monitors incoming signals for consistency and safety. If it detects a problem, such as a sudden loss of signal or an out-of-range command, it can stop the motor instantly to prevent damage.

Tip: Always update your ESC firmware to the latest version. Newer firmware often improves signal processing speed and reliability.

Energizing Coils

The ESC’s main job is to control the flow of electricity to the motor coils. When you start your drone, the ESC energizes the coils in a specific sequence to create a rotating magnetic field. This field causes the rotor to turn and the motor to spin up.

At startup, the ESC faces a challenge. The motor is stationary, so there is no back electromotive force (back EMF) to provide feedback about the rotor’s position. To overcome this, the ESC uses an open-loop method. It energizes the coils in a fixed pattern, giving the rotor an initial push. As the motor gains speed, back EMF signals appear. The ESC then switches to closed-loop control, using these signals to time the coil energization more accurately.

- The ESC uses a microcontroller to process your commands and control the MOSFET switches.

- During startup, the ESC energizes the coils in a predetermined sequence because no back EMF is present.

- Once the motor spins fast enough, the ESC detects back EMF and adapts the timing for efficient operation.

- Sensorless ESCs use techniques like zero crossing detection and ADC sampling to read back EMF signals.

- The ESC’s ability to switch from open-loop to closed-loop control ensures smooth and reliable motor startup.

This process allows your drone to start quickly and transition to efficient operation as soon as possible.

Safety Features

You benefit from several built-in safety features in modern ESCs. These features protect both your drone and its electronics from unexpected problems. The ESC monitors voltage, current, and temperature in real time. If it detects a dangerous condition, such as overheating or a short circuit, it can shut down the motor to prevent damage.

ESCs also include signal loss protection. If your remote controller loses connection or sends erratic commands, the ESC will stop the motor or enter a failsafe mode. This reduces the risk of crashes and protects people and property nearby.

Studies on electronic stability systems in vehicles show that similar safety features can reduce fatal crashes by up to 70-90% in certain conditions. While these studies focus on cars, the principles apply to drones as well. Reliable ESC safety features help you maintain control during sudden signal fluctuations or unexpected events.

Note: Always check your ESC’s safety settings before each flight. Proper configuration can prevent accidents and extend the life of your equipment.

Calibration

You need to calibrate your ESCs to ensure accurate and reliable motor control. Calibration aligns the ESC’s throttle range with your flight controller or remote controller. Without proper calibration, you may experience issues such as delayed motor response, uneven spin-up, or even failure to start. Calibration helps the ESC interpret your throttle signals correctly, which leads to smoother takeoffs and more precise flight control.

You should perform ESC calibration whenever you install new ESCs, change your flight controller, or notice irregular motor behavior. Many pilots also recalibrate after firmware updates or major repairs. Calibration is a straightforward process, but you must follow each step carefully to avoid damaging your electronics.

Here is a typical ESC calibration procedure:

- Disconnect the propellers for safety.

- Power on your remote controller and set the throttle stick to maximum.

- Connect the battery to your drone. The ESCs will emit a series of beeps, indicating they are ready for calibration.

- Lower the throttle stick to the minimum position. The ESCs will confirm calibration with another set of beeps.

- Disconnect the battery and reconnect it to complete the process.

Tip: Always remove the propellers before calibrating. This step prevents accidental spin-up and reduces the risk of injury.

Some ESCs support automatic calibration, while others require manual steps. You should consult your ESC’s manual for specific instructions. Modern ESCs with digital protocols like DShot often do not need calibration, but analog ESCs using PWM signals almost always require it.

Calibration ensures that the ESC recognizes the full range of your throttle input. If you skip this step, you might notice that the motors do not respond until the throttle stick is halfway up, or they may not reach full power. Proper calibration eliminates these problems and improves your drone’s responsiveness.

| Calibration Step | Purpose | Result |

|---|---|---|

| Remove propellers | Safety | Prevents accidental spin-up |

| Max throttle, power on | Set high endpoint | ESC enters calibration mode |

| Min throttle | Set low endpoint | ESC saves throttle range |

| Reconnect battery | Finalize calibration | ESC ready for operation |

You should repeat calibration if you notice any throttle inconsistencies or after making hardware changes. Regular calibration keeps your ESCs and motors working together smoothly, which leads to safer and more predictable flights.

Troubleshooting

Common Issues

You may encounter several issues when starting your drone. Many startup failures relate to physical or electrical resistance rather than faulty starter components. You should check for these common problems:

- ESCs are sensitive to physical resistance. Even slightly overlapping or bent propellers can prevent the motor from starting.

- Internal motor resistance can increase due to hidden damage. This may cause intermittent failures that are hard to spot.

- Debris or broken propeller pieces lodged inside the motor can block rotation. This can lead to startup failures or sudden stops during flight.

- The motor relies on electromagnetic forces from energized windings to begin spinning. Capacitors do not play a direct role in starting the motor.

- Intermittent startup errors are serious. If you notice a motor that sometimes fails to start, you should repair it before flying. All motors must work properly for safe flight.

Tip: Always inspect your propellers and motors before each flight. Remove any debris and replace damaged parts immediately.

Signal Problems

Signal issues can prevent your drone from starting or cause unstable motor performance. You may notice symptoms such as motors failing to start, motors not reacting, or unstable speeds. These problems often point to signal transmission faults between the flight controller, ESC, and sensors.

- ESC calibration problems can disrupt motor speed control.

- Sensor failures, such as a malfunctioning Hall sensor or current sensor, can stop the motor from receiving accurate position or current data.

- Electromagnetic interference may disrupt signals between the ESC and motor.

- You can diagnose these issues by:

- Using Hall sensor detection tools to check signal stability.

- Measuring current sensor output voltage with a multimeter during operation.

- Monitoring signal output and motor RPM with flight control debugging software.

- Solutions include recalibrating the ESC, replacing faulty sensors, shielding cables, changing your flight site to reduce interference, and checking for extra load from mounted equipment or damaged propellers.

Note: Advanced diagnostic methods, such as analyzing vibration signals with accelerometers and machine learning, can help identify propeller blade faults without extra sensors. This approach uses vibration data to detect subtle issues during startup.

Power Supply Checks

A stable power supply is essential for reliable motor startup. If your drone does not start, you should check the battery and power connections first. Low battery voltage or poor connections can cause weak or failed startups. Inspect the battery for swelling, overheating, or rapid voltage drops. Replace any battery that shows these signs.

You should also examine the power wires and connectors. Loose or corroded connectors can interrupt the flow of electricity. Make sure all connections are tight and clean. If you use a power distribution board, check for burnt traces or damaged solder joints. These can cause voltage drops that prevent the ESC from delivering enough power to the motor.

| Power Supply Issue | What to Check | Recommended Action |

|---|---|---|

| Low battery voltage | Battery charge and health | Recharge or replace battery |

| Loose connectors | All power wires and plugs | Tighten or clean connectors |

| Damaged wiring | Frayed or burnt wires | Replace damaged wires |

| Faulty distribution board | Solder joints and traces | Repair or replace board |

Tip: Always use a fully charged, healthy battery and inspect all power connections before each flight. This simple habit prevents many startup failures.

ESC and Motor Faults

You may encounter faults in either the ESC or the motor during startup. These faults often present unique symptoms that you can identify with careful observation and sensor data. When you understand these patterns, you can prevent further damage and improve your troubleshooting skills.

ESC faults frequently arise from component failures, such as a faulty MOSFET transistor. For example, a study on BLDC motors in UAVs found that a defective FDD8896 MOSFET in the ESC caused the motor to stop after about 80 seconds at 4000 RPM. The ESC entered protection mode due to high current variations and amplitude. This type of fault not only interrupts operation but also doubles energy consumption compared to healthy systems. You may notice increased noise and vibration, which signal that the ESC is struggling to maintain stable performance.

Motor faults can develop from prolonged operation under faulty ESC conditions. When the ESC fails to regulate current properly, the stator winding insulation may degrade. This leads to permanent motor failure if you do not address the issue quickly. You should pay attention to changes in temperature, current, and acceleration during startup. These parameters often show the highest amplitudes when an ESC fault is present. As rotor speed increases, these values rise, creating a distinct signature for each type of fault.

You can use sensor modules like the MPU9250 for acceleration, BMP180 for temperature, and INA3221 for electrical current to monitor your system. These sensors collect valuable data during startup and normal operation. By analyzing this data, you can detect abnormal patterns before they cause serious problems. Machine learning classifiers, such as SVM, KNN, and BN, have shown high accuracy in identifying and classifying ESC and motor faults based on sensor data. This approach allows you to distinguish between healthy systems, chipped propellers, eccentric shafts, and ESC faults.

Here are some key indicators of ESC and motor faults:

- Sudden increase in current draw or temperature during startup

- Noticeable rise in vibration or noise from the motor area

- Motor stops unexpectedly or fails to reach target speed

- ESC emits warning beeps or enters protection mode

- Energy consumption spikes, even at moderate speeds

Tip: Always monitor sensor data during startup. Early detection of abnormal readings can help you avoid costly repairs and ensure safe operation.

If you suspect an ESC or motor fault, stop using the drone immediately. Inspect the ESC for visible damage, such as burnt components or a strong odor. Check the motor for signs of overheating or physical wear. Replace any damaged parts before your next flight to maintain reliability and safety.

Tips

Pre-Flight Checks

You should always perform thorough pre-flight checks before starting your drone. These checks help you catch issues early and prevent accidents. Start by inspecting the physical condition of your drone. Look for cracks, loose screws, or damaged propellers. Make sure the battery is fully charged and securely attached.

Next, focus on your drone’s electronic systems. Power on your remote controller first, then the drone. Watch for any error messages or unusual beeps during startup. Confirm that all lights and indicators show normal status.

A reliable pre-flight checklist includes:

- Inspecting the airframe and propellers for damage

- Checking battery voltage and health

- Verifying that the remote controller is bound to the drone

- Ensuring GPS lock and sensor calibration

- Confirming that all switches and controls are in their correct positions

Tip: Many flight controllers perform automatic pre-arm checks. These checks include accelerometer and gyroscope calibration, board voltage verification, and parameter validation. If any check fails, the system will not arm the motors, keeping your drone safe.

Connections

You need to ensure all connections are secure before every flight. Loose or corroded connectors can cause signal loss or power interruptions. Check the battery leads, ESC wires, and motor plugs. Gently tug each connection to confirm it is tight.

Pay special attention to the antenna connections on both the drone and the remote controller. A weak or broken antenna can lead to signal loss and loss of control. Inspect the solder joints on your flight controller and ESCs. Cold or cracked solder joints may cause intermittent failures.

A quick connection checklist:

- Battery leads and connectors

- ESC-to-motor wires

- Flight controller plugs and solder joints

- Antenna mounts and cables

Note: Integrated motor and ESC designs with position sensing improve reliability. Tight motor-ESC pairing and sophisticated control software also help prevent connection-related failures.

Firmware Updates

You should keep your drone’s firmware up to date. Firmware updates often include important safety improvements and new features. Updated firmware can fix bugs that might cause unsafe motor arming or unexpected behavior.

Recent analysis of UAV software platforms shows that many crashes and motor failures result from outdated or faulty firmware. Problems like improper failsafe behavior, missing safety switch handling, and weak arming checks have led to unsafe conditions. Updating your firmware helps address these issues by improving failsafe logic, sensor data filtering, and safety switch management.

Key firmware update benefits include:

- Enhanced over-current, over-voltage, and over-temperature protection

- Improved motor health monitoring

- Safer arming procedures

- Better integration between motor and ESC

- More reliable sensor calibration and validation

Tip: Always review the release notes before updating. After an update, recalibrate your sensors and verify all settings. This step ensures your drone operates safely and takes full advantage of the latest improvements.

Safe Arming

Safe arming is one of the most important habits you can develop as a drone pilot. When you arm your drone, you enable the motors to spin and prepare the aircraft for flight. If you do not follow safe arming procedures, you risk accidental motor spin-up, property damage, or even personal injury. You need to treat arming as a critical safety step every time you fly.

You should always follow these best practices for safe arming:

- Clear the Area: Make sure no one stands near your drone. Keep pets, children, and bystanders at a safe distance. You want a clear takeoff zone with no obstacles.

- Remove Propellers During Setup: When you work on your drone or update firmware, always remove the propellers. This prevents accidental spin-up if the motors arm unexpectedly.

- Power On in the Correct Order: Turn on your remote controller first, then connect the drone battery. This ensures you have control before the drone receives power.

- Check Throttle Position: Confirm that your throttle stick is at its lowest setting before arming. High throttle at startup can cause the motors to spin at full speed.

- Use Arming Switches or Stick Combos: Most drones require a specific switch or stick movement to arm. This prevents accidental arming from a single button press.

- Listen for Confirmation Beeps: Your ESCs or flight controller will usually beep or flash lights when the drone arms. Wait for these signals before applying throttle.

- Visually Inspect the Drone: Look for loose wires, damaged propellers, or anything unusual before arming. Fix any issues before you proceed.

Tip: Always announce your intention to arm the drone if others are nearby. A simple “Arming motors!” can prevent surprises and keep everyone alert.

You can use this quick reference table to remember safe arming steps:

| Step | Why It Matters |

|---|---|

| Clear the area | Prevents injury and property damage |

| Remove propellers for setup | Stops accidental spin-up |

| Power on remote first | Ensures control before power-up |

| Check throttle position | Avoids sudden motor acceleration |

| Use arming switch/combo | Reduces risk of accidental arming |

| Wait for confirmation | Confirms system is ready |

| Inspect drone visually | Catches problems before flight |

Modern flight controllers include safety features like pre-arm checks and arming locks. You should never bypass these systems. If your drone refuses to arm, investigate the warning instead of forcing it. These features exist to protect you and your equipment.

Note: Practicing safe arming every time builds good habits. You reduce the risk of accidents and show professionalism as a drone pilot.

By following these steps, you ensure that every flight begins safely and responsibly. Safe arming protects you, your drone, and everyone around you.

Summary

Key Steps

You follow a clear sequence when starting your drone motor. First, you power on the drone and remote controller. Next, you arm the motors using a specific stick movement or switch. After arming, you apply throttle input. The flight controller processes your command and sends it to the ESC. The ESC energizes the motor coils in a timed pattern. As the motor spins up, the ESC detects back-EMF and switches to sensorless control. This process ensures a smooth and reliable startup every time.

Tip: Always move through each step carefully. Skipping a step can lead to startup failures or unsafe conditions.

Component Roles

Each component in your drone plays a unique role in starting the drone motor:

- Remote Controller: Sends your commands to the drone.

- Flight Controller: Interprets your input and manages safety checks.

- ESC: Converts signals into precise power delivery for the motor.

- Battery: Supplies the energy needed for startup and flight.

- Motor: Converts electrical energy into mechanical rotation.

You rely on the connection between these parts for a successful launch. If one component fails, the entire startup sequence can break down.

| Component | Main Function |

|---|---|

| Remote Controller | Sends pilot input |

| Flight Controller | Processes signals and checks safety |

| ESC | Controls power to the motor |

| Battery | Provides electrical energy |

| Motor | Spins propellers for lift |

Final Notes

You improve safety and reliability by understanding the startup sequence and each component’s function. Always check your connections and battery health before each flight. Update your firmware regularly to benefit from the latest safety features. If you notice any issues during startup, use the troubleshooting steps to find and fix the problem quickly.

Remember: A well-maintained drone motor and careful pre-flight routine help you achieve smooth takeoffs and safe flights every time.

You now understand how each component works together to start your drone motor. The process begins with your command and moves through the flight controller, ESC, and battery before the motor spins up. Knowing the startup sequence helps you prevent issues and keep your drone safe. If you face any problems, review the troubleshooting section for quick solutions. Mastering these basics gives you more confidence and control in every flight.