You see the FPV drone motor convert electrical energy into powerful mechanical motion. The stator, rotor, magnets, and windings work together, while the ESC and flight controller regulate performance. Efficiency depends on the right combination of KV rating, stator volume, and battery pairing, as shown by significant improvements in payload and endurance.

FPV Drone Motor Parts

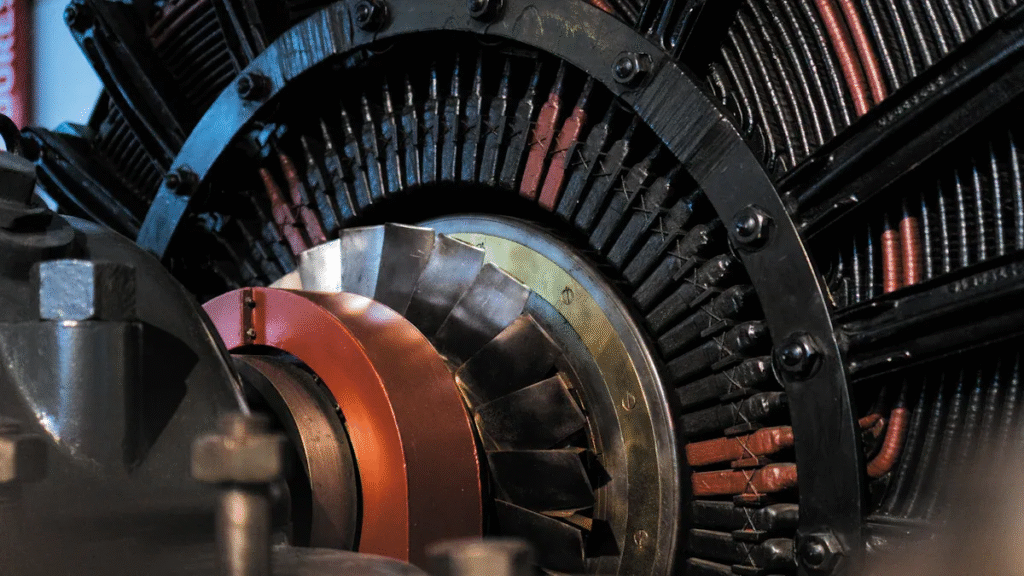

When you examine an FPV drone motor, you find several essential components working together to deliver reliable performance. Most FPV drone motors use a brushless design. This approach eliminates friction and wear from brushes, giving you higher efficiency, longer lifespan, and smoother operation—key advantages for demanding FPV flights.

Stator and Rotor

The stator forms the stationary core of the motor. It contains tightly wound copper coils that generate a magnetic field when energized. The rotor sits inside or around the stator and holds powerful magnets. As the stator’s magnetic field changes, it causes the rotor to spin rapidly. The design of the stator directly affects how your FPV drone motor performs.

| Stator Design Element | Performance Impact on FPV Drone Motor Output |

|---|---|

| Number of Poles (N) and Magnets (P) | Higher counts lead to smoother operation, reduced cogging torque, better torque output, and improved responsiveness. Lower counts favor higher RPM but less torque. |

| Motor Size (Stator Diameter & Height) | Larger stators produce more torque, suitable for bigger propellers and heavier payloads; smaller stators are lighter and more responsive but with less thrust. |

| KV Rating (RPM per Volt) | Lower KV motors provide more torque and better control for larger props; higher KV motors spin faster but with less torque, suited for speed-focused drones. |

| Torque Characteristics | Increased torque from higher pole/magnet counts enables quicker response to control inputs, essential for stable flight and agile maneuvers. |

| Efficiency and Control | More poles/magnets reduce cogging torque, enhancing smoothness and control, which is critical for FPV drone stability and precision. |

Magnets and Windings

You rely on high-quality magnets and precise windings for consistent power and efficiency. Even a small flaw in magnet coating can cause propeller speed to fluctuate by over 15%, making stable hovering difficult. If the stator slot fill rate drops below 72%, you may notice mid-flight spasms. Poor winding quality has led to drone failures during live events, so manufacturers now use industrial endoscopes to inspect copper wire arrangement.

- Thinner magnet coatings can cause speed fluctuations and instability.

- Low stator slot fill rates often result in erratic flight behavior.

- Substandard winding processes have caused multiple drone failures.

- Careful inspection of windings ensures long-term reliability.

Bearings and Shaft

Bearings support the shaft, allowing it to spin smoothly with minimal friction. The shaft connects the rotor to the propeller, transferring the motor’s rotational force. High-quality bearings reduce vibration and noise, helping your FPV drone motor run quietly and efficiently.

How It Works

ESC and Flight Controller

You rely on the electronic speed controller (ESC) and the flight controller to manage every movement of your FPV drone motor. The flight controller acts as the brain, processing your stick inputs and sensor data. It sends precise signals to the ESC, which then adjusts the amount of electrical current delivered to the stator windings. This process happens in milliseconds, allowing you to make rapid adjustments during flight. The ESC uses these signals to control the timing and strength of the current pulses, which directly influence how fast and in which direction the motor spins. This seamless communication ensures that your drone responds instantly to your commands, whether you want to hover, accelerate, or perform complex maneuvers.

Motor Operation Steps

When you activate the throttle, the ESC sends a series of electrical pulses to the stator windings inside the FPV drone motor. These pulses create a rotating magnetic field. The magnets on the rotor follow this field, causing the rotor and attached propeller to spin. This conversion of electrical energy into mechanical rotation forms the core of how your drone generates lift and movement.

You can see the impact of each operation step on efficiency and performance in the table below:

| Parameter | Numerical Values / Ranges | Impact on Efficiency and Performance |

|---|---|---|

| Motor Efficiency | 70% vs 90% | 70% efficiency means 30% energy lost as heat; 90% means only 10% loss, affecting heat generation and flight time |

| Thrust-to-Weight Ratio | 3:1, 4:1 (steady flight) to 5:1 (competition) | Higher ratio improves agility and acceleration but may reduce control stability |

| KV Rating Ranges | 1000-1600KV (long-range), 1600-2200KV (cinematic), 2200-2700KV (freestyle), 2700-3500KV (racing), 3500-4500KV (whoops) | Lower KV motors have higher efficiency and torque; higher KV motors have faster response but higher power draw and heat |

| Motor Weight | 20g to 50g (typical range) | Heavier motors may affect thrust-to-weight ratio and overall efficiency |

You achieve higher efficiency and longer flight times by selecting motors with higher efficiency ratings and matching them with the right ESC and battery setup. Lower efficiency means more energy lost as heat, which can shorten your flight and increase the risk of overheating.

Thrust and Control

You control the drone’s movement by adjusting the speed and direction of each FPV drone motor. The ESC varies the current to each motor, allowing you to change thrust levels instantly. When you increase the speed of one motor while decreasing another, you tilt and turn the drone in the air. This precise control over thrust and direction is essential for stable flight and agile maneuvers.

Modern drones, such as the FLOAT Drone, use advanced designs that allow you to manage forces and torques along all three axes. By independently controlling the speed of each rotor, you can maintain stable hovering, even when the drone tilts or faces wind gusts. Real-world tests show that accurate thrust measurement and management lead to precise flight control. For example, coaxial propeller systems demonstrate that thrust distribution directly affects stability and maneuverability. You need to monitor and adjust thrust values to ensure your drone remains balanced and responsive during flight.

Tip: Always monitor motor temperature and thrust output during flights. Consistent performance and stable control depend on keeping your FPV drone motor within optimal operating ranges.

Performance Factors

KV Rating and Size

You need to pay close attention to the KV rating and size when selecting a motor for your FPV drone. The KV rating tells you how many revolutions per minute (RPM) the motor will spin for each volt applied. A higher KV rating means faster spinning, which gives you more thrust and quicker response, but it also increases power draw and heat. Lower KV motors provide better efficiency and more torque, making them ideal for larger propellers and longer flights.

| UAV Type | Motor KV | Motor Weight (g) | Propeller Size (inches) | Approx. Hover RPM |

|---|---|---|---|---|

| Small Commercial Quadrotor | 420 | 2845 | 13 × 4.5 | 5000 |

| Custom-Built Hexarotor | 340 | 5660 | 17 × 5.8 | 4000 |

You can see that larger drones use lower KV motors and bigger propellers, which helps with efficiency and stability. Testing shows that matching KV, propeller size, and battery voltage leads to optimal thrust and flight time.

Efficiency and Cooling

You want your FPV drone motor to run efficiently and stay cool. Efficient motors waste less energy as heat, giving you longer flights. Cooling plays a big role in motor longevity. Outrunner motors, with their open design, allow more airflow and keep temperatures lower than inrunner motors.

| Motor Type | Temperature Rise after 10 min at 80% Load | Flight Time Increase | Temperature Difference after Race |

|---|---|---|---|

| Outrunner | 30°C | +12% | 15°C lower than inrunner |

| Inrunner | 45°C | N/A | N/A |

Lower temperatures mean your motor lasts longer and performs more consistently, especially during demanding flights.

Motor Variations

You will find two main types of motors in FPV drones: inrunner and outrunner. Outrunner motors dominate the FPV drone market because they offer better cooling and higher torque at lower RPMs. Inrunner motors spin faster but often overheat and provide less torque for the same size. You should also know that almost all modern FPV drone motors are brushless. Brushless motors last longer, run more efficiently, and require less maintenance than brushed motors.

Tip: Always match your motor type and KV rating to your drone’s size and flying style for the best performance.

You see how each motor part and control system shapes your drone’s flight. Motor design choices—like weight, KV rating, and efficiency—directly affect thrust, agility, and reliability.

- Lightweight motors improve responsiveness.

- Higher efficiency extends flight time.

- Larger stators boost torque and heat dissipation.

| Parameter | Range/Example | Impact |

|---|---|---|

| Thrust-to-Weight | 3:1 to 5:1 | More agility, less stability |

| Efficiency | 70% to 90% | Longer life, less heat |

Choose motors that match your flying style and maintain them for consistent performance.