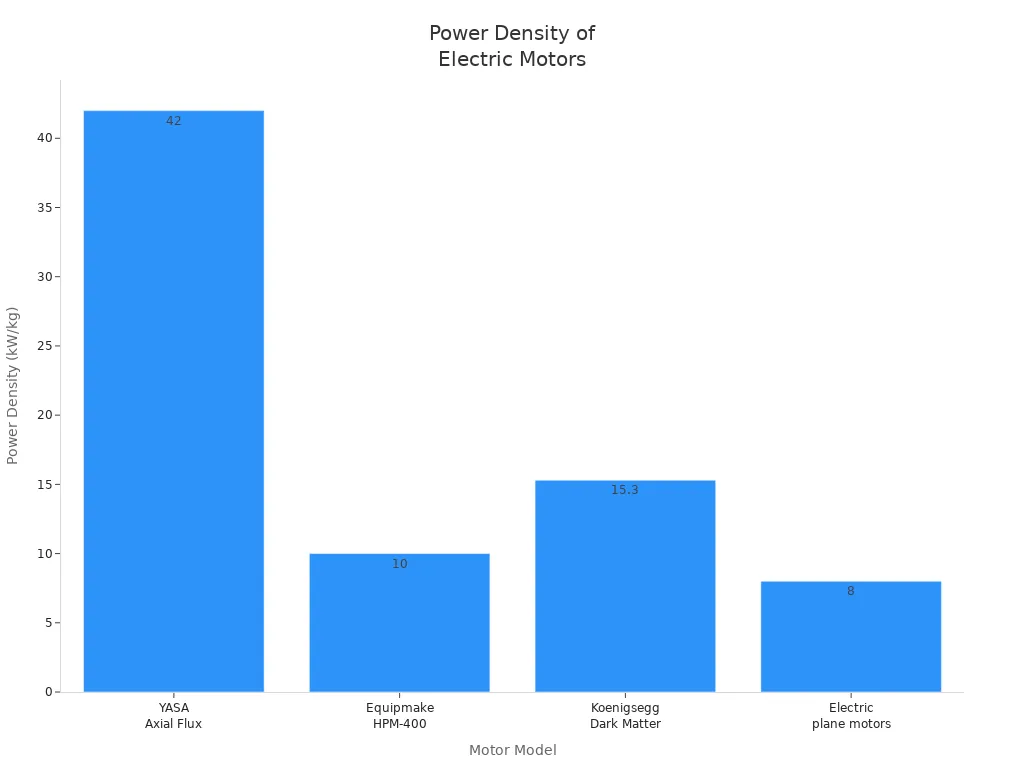

YASA, a Mercedes-Benz company, produces the world’s most power dense electric motor. Their axial flux motor delivers 550 kW (738 hp) from just 13.1 kg, achieving 42 kW/kg—nearly double the previous industry benchmark. The table below shows how YASA’s design outperforms other leading motors:

| Motor Model | Power Output | Weight (kg) | Power Density (kW/kg) | Power Density (hp/kg) | Notes |

|---|---|---|---|---|---|

| YASA Axial Flux Motor | 550 kW | 13.1 | 42 | ~56.3 | Nearly double industry benchmark; 738 hp at 13.1 kg |

| Equipmake HPM-400 | 400 kW | 40 | 10 | 13.4 | Industry benchmark before YASA |

| Koenigsegg Dark Matter | ~597 kW | 39 | 15.3 | 20.5 | High-performance motor, heavier than YASA |

| Electric plane motors | N/A | N/A | ~8 or less | N/A | YASA exceeds by more than factor of 5 |

This leap in power density means engineers can design lighter, more efficient systems for vehicles and aerospace, where every kilogram counts.

Key Takeaways

- YASA’s axial flux motor delivers the highest power density in the world, producing 550 kW from just 13.1 kg, nearly doubling previous industry records.

- High power density means lighter, smaller motors that improve vehicle efficiency, acceleration, and range, especially important for cars and aircraft.

- YASA’s unique motor design uses advanced materials, oil cooling, and a yokeless, segmented structure to boost performance and keep the motor cool.

- This technology is already used by top car makers like Ferrari, Lamborghini, and Mercedes-Benz, helping create faster and more efficient electric and hybrid vehicles.

- Future electric motors will continue to improve with better cooling, materials, and designs, supporting cleaner transportation and new industries like urban air mobility.

Power Density in Electric Motors

What Is Power Density?

Power density describes how much power a device can produce for its size. In electric motors, engineers define power density as the amount of power generated per unit volume. This measurement shows how much energy a device can deliver from a given space. The typical units for power density are watts per cubic meter (W/m³) or watts per cubic inch (W/in³). To calculate power density, divide the output power by the device’s volume. For example, if a device produces 500 watts and has a volume of 0.05 cubic meters, its power density is 10,000 W/m³.

Note: Power density is different from energy density. Power density measures how quickly energy can be delivered, while energy density measures how much total energy can be stored.

Several factors influence power density. These include the design of the device, the materials used, and the cooling methods. Engineers often improve power density by optimizing the shape, using advanced magnetic materials, and enhancing cooling systems. For example, direct oil cooling and special magnet placement can help increase the amount of power produced without overheating.

Why Power Density Matters

High power density offers many advantages in transportation and industry. In electric vehicles and aircraft, a higher power density means lighter and smaller propulsion systems. This reduction in weight leads to better efficiency, faster acceleration, and longer range. In aviation, lighter motors reduce takeoff weight and drag, making electric flight more practical.

- Compact designs allow for distributed propulsion in aircraft and easier integration in cars.

- Advanced cooling and materials help maintain high performance without overheating.

- Integrated drives and electronics shrink the size and weight of control systems.

However, increasing power density also brings challenges. Devices generate more heat, which requires advanced cooling. Stronger materials and precise manufacturing become necessary to handle higher stresses and vibrations. Engineers must balance these factors to achieve the best performance without sacrificing reliability or safety.

YASA Axial Flux Motor

Key Specs and Performance

YASA’s axial flux motor stands as the current record-holder for power density, delivering up to 56 bhp per kilogram. This achievement results from a combination of advanced engineering and material science. The motor produces a peak power of 550 kW from only 13.1 kg, making it nearly twice as power dense as previous industry leaders.

The following table summarizes the main technical specifications of the YASA-400 model, which represents the core of YASA’s product lineup:

| Parameter | Value |

|---|---|

| Peak Torque | 360 Nm |

| Continuous Torque | 250 Nm |

| Peak Power @ 350V | 90 kW |

| Peak Power @ 700V | 165 kW |

| Continuous Power | 85 kW |

| Maximum Speed | 7500 rpm |

| Total Weight | 24 kg |

| Total Volume | 6 liters |

| Axial Length | 75 mm |

| Diameter | 280 mm |

| Coolant | Oil |

| Coolant Flow Rate | 6-10 L/min |

| Fluid Volume | 0.6 L |

| Peak Efficiency | >95% |

YASA offers several motor models, each optimized for different applications. The YASA-750 delivers up to 800 Nm of torque and 75 kW of continuous power, while the YASA-250 reaches speeds up to 9000 rpm. The chart below compares torque, speed, and power across the YASA-750, YASA-400, and YASA-250 models:

YASA’s motors achieve peak efficiency above 95%. The oil cooling system allows for higher continuous power output, supporting demanding automotive and aerospace applications. The compact size and low weight enable engineers to design lighter vehicles with improved acceleration and range.

YASA’s technology has already found its way into high-performance vehicles. Manufacturers such as Ferrari, Lamborghini, and Mercedes-Benz use YASA motors in their flagship hybrid and electric models. For example, the Ferrari SF90 Stradale and Lamborghini Revuelto both rely on YASA’s axial flux motors for their hybrid drivetrains. Mercedes-Benz plans to deploy these motors in upcoming electric and hybrid vehicles, including the CONCEPT AMG GT XX.

| Manufacturer | Vehicle Model | Deployment Details |

|---|---|---|

| Ferrari | SF90 Stradale | Hybrid vehicle using YASA axial flux motors |

| Lamborghini | Revuelto | Flagship hybrid sports car combining YASA motors with a V12 petrol engine |

| Mercedes-Benz / Mercedes-AMG | Various (including BEVs and hybrids) | Scaling production for hybrid and full BEV applications; BEV sports car planned |

Innovations Behind the Motor

Several unique design features set the YASA axial flux motor apart from traditional radial flux motors:

- The yokeless and segmented architecture removes the heavy stator yoke, reducing weight and iron losses. This design increases efficiency and allows for a thinner, lighter motor.

- The dual-rotor, single-stator structure uses two outer rotors and a segmented inner stator. This arrangement supports high torque density and simplifies manufacturing.

- Short end windings reduce copper loss and improve the slot fill factor, which means more copper fits into the same space, boosting performance.

- The stator uses Soft Magnetic Composite (SMC) materials. These materials, made from insulated ferromagnetic particles, allow for complex shapes and isotropic magnetic properties, further improving efficiency.

- The motor’s cooling system uses direct oil cooling. Oil circulates around the windings and stator teeth, quickly removing heat and enabling higher continuous power. This system also improves safety, as oil is an electrical insulator.

Note: The advanced cooling system places stator coils close to cooling fins with integrated water-cooling pipes. This setup reduces thermal resistance and allows the motor to operate at higher power without overheating. Engineers have optimized the cooling fin height and system parameters, lowering winding temperatures and increasing peak output power by up to 30%.

Material science plays a crucial role in these innovations. The use of advanced composites and high-performance polymers enables the motor to remain lightweight while handling high temperatures and stresses. These materials also allow for more compact designs, making the motor suitable for tight spaces in sports cars and aircraft.

Additive manufacturing techniques further support the creation of complex cooling channels and lightweight structures. While traditional manufacturing remains more cost-effective for large-scale production, additive methods reduce material waste and enable rapid prototyping of new designs.

Automotive manufacturers value these innovations because they enable lighter, more efficient vehicles. YASA’s motors help reduce battery size or extend driving range, supporting the shift toward electrification in the automotive industry.

Comparing Leading Motors

Previous Record Holders

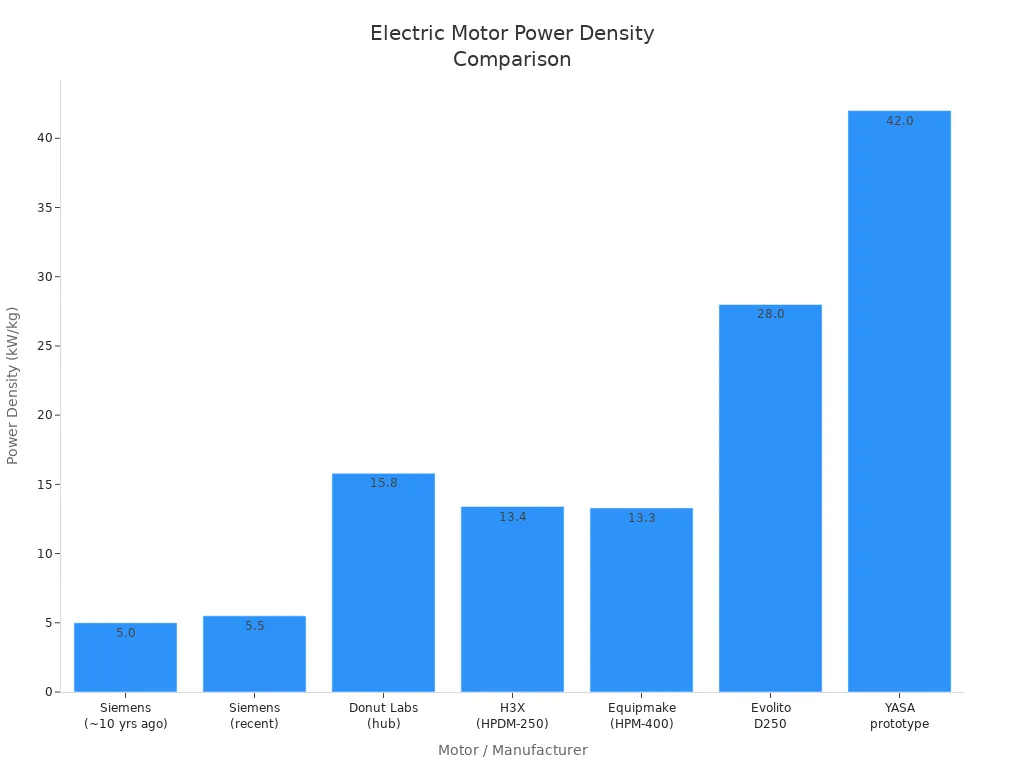

Before YASA set a new benchmark, several companies held records for power density in electric motors. Equipmake’s HPM-400 previously led the field with a power density of 54 bhp/kg. Siemens also achieved notable results, with earlier motors reaching 5.0 kW/kg and later models improving to 5.5 kW/kg. Donut Labs and H3X Technologies pushed the boundaries further, but none matched YASA’s achievement.

| Record Holder | Power Density Figure | Notes |

|---|---|---|

| YASA (UK) | 56 bhp/kg | Unofficial world record for motor power density with a 738bhp, 13.1kg motor |

| Equipmake HPM-400 | 54 bhp/kg | Highest power-to-weight ratio in production before YASA’s claim |

| Siemens (Germany) | ~5.5 kW/kg | Previous industry high mark |

| Donut Labs | 15.8 kW/kg | Previously called world record in automotive motors |

| H3X HPDM-250 | 13.4 kW/kg | Aerospace motor |

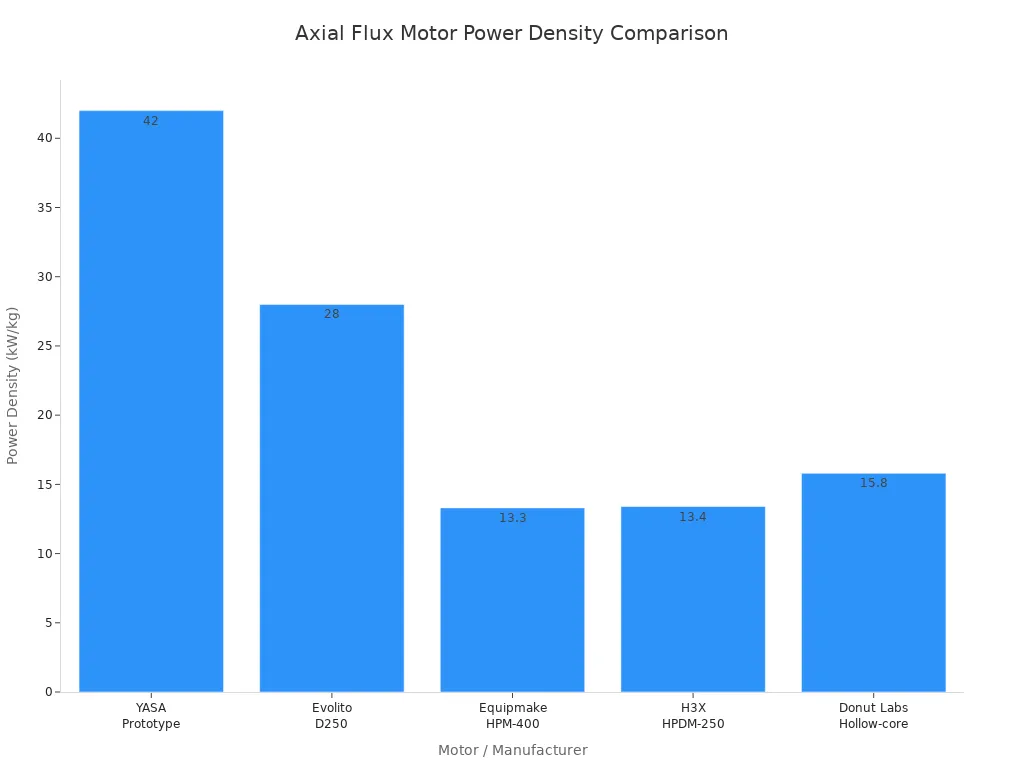

YASA’s prototype motor achieves 42 kW/kg, more than double the figures of previous leaders. The following chart visually compares these advancements:

Notable Competitors

Several companies continue to innovate in high power density motors. Equipmake, H3X Technologies, Koenigsegg, and Evolito (a YASA spinoff) all produce advanced designs. Equipmake’s HPM-400 and H3X’s HPDM-250 both reach around 13.3–13.4 kW/kg, focusing on aerospace and marine applications. Donut Labs’ hollow-core motor achieves 15.8 kW/kg for automotive use. Evolito’s D250 stands out among competitors, reaching 28 kW/kg, the only other motor to surpass half of YASA’s figure.

| Motor / Manufacturer | Power Density (kW/kg) | Application |

|---|---|---|

| YASA Prototype Motor | 42 | Automotive |

| Evolito D250 (YASA spinoff) | 28 | Aerospace |

| Equipmake HPM-400 | ~13.3 | Aerospace/Marine |

| H3X HPDM-250 | ~13.4 | Aerospace |

| Koenigsegg Dark Matter | N/A | Axial flux motor |

| Donut Labs Hollow-core | 15.8 | Automotive |

YASA’s motor stands apart not only for its record-setting power density but also for its focus on scalable, cost-effective production. While most competitors target aerospace or high-performance vehicles, YASA designs its technology for mass-market automotive use. The company’s unique yokeless and segmented architecture, direct coil cooling, and use of standard materials enable both high efficiency and manufacturing scalability. In contrast, competitors often rely on lightweight composite rotors or focus on short-duration performance, which can limit continuous power output and production scale.

Real-World Impact

Applications in Industry

YASA’s axial flux technology has transformed the automotive sector. Leading manufacturers such as Mercedes-Benz have adopted these high-performance systems in next-generation electric vehicles. Their design achieves up to 50% more power output per unit weight than traditional radial-flux designs. This improvement allows automakers to build lighter, more efficient vehicles with better acceleration and range. YASA expanded its manufacturing capacity to over 25,000 units annually, showing strong demand and real-world success.

- Automotive industry: YASA specializes in high-performance solutions for electric vehicles, delivering lightweight and efficient propulsion.

- Collaborations: Partnerships with major brands like Mercedes-Benz validate the technology’s reliability and performance.

- Broader adoption: Beyond cars, axial flux designs are gaining traction in aerospace, marine, and general manufacturing.

- Industrial benefits: In manufacturing and robotics, these systems provide high torque at low speeds, compact size, and improved heat dissipation. Companies see longer equipment lifespan and reduced maintenance costs.

YASA’s technology supports sustainability by reducing material usage and energy waste. Efficient operation enables smaller batteries, lowering environmental impact from battery production and electricity consumption.

Future Potential

High power density electric systems will play a critical role in emerging industries. Urban air mobility (UAM) stands out as a major growth area. Lightweight, modular, and scalable designs meet strict aviation safety standards and enable distributed propulsion for eVTOL aircraft. Advances in materials, such as carbon fiber composites and improved magnetic alloys, continue to drive higher power density and better thermal performance.

- Urban air mobility: High power density enables quieter, more efficient vertical takeoff and landing vehicles.

- Robotics: Compact, efficient systems support automation and precision in industrial robots.

- Technological advancements: Innovations like hairpin winding, direct oil cooling, and rare earth-free magnets promise even greater efficiency and sustainability.

- Environmental impact: Future designs aim to reduce reliance on rare earth materials, lower CO2 emissions, and improve recyclability.

The next decade will see rapid scaling and integration of these technologies, supporting cleaner, more efficient transportation and manufacturing worldwide.

YASA’s axial flux motor sets a new benchmark for power density, enabling lighter and more efficient electric vehicles. This achievement drives the industry to adopt advanced designs and materials, improving performance and reducing environmental impact.

- Ongoing innovation in electric motor technology supports cleaner transportation, cost savings, and greater energy security.

- Researchers now focus on new topologies, better cooling, and rare earth-free designs.

Future breakthroughs will likely come from integrating electronics and optimizing every part of the system.