A brushless drone motor powers your drone by turning electrical energy into motion. You get higher efficiency because the motor reduces friction and heat. This means your drone flies longer and responds quickly to your commands. You can rely on this motor for consistent performance and low maintenance, making it an essential choice for both professional and hobbyist drones.

- Efficient energy conversion boosts flight time.

- Reliable design supports stable operation.

Key Takeaways

- Brushless drone motors convert electrical energy into motion efficiently, giving your drone longer flight times and smoother control.

- The motor’s main parts, the stator and rotor, work together with designs like integrated fan rotors to boost torque and cool the motor for better performance.

- Matching the motor’s KV rating, propeller size, and battery voltage is key to balancing speed, torque, and flight time for your drone’s specific needs.

- Brushless motors last much longer and need less maintenance than brushed motors, saving you time and money while improving reliability.

- Choosing the right brushless motor improves your drone’s efficiency, payload capacity, and flight stability, making it ideal for both hobbyists and professionals.

Brushless Drone Motor Structure

Stator and Rotor

You find two main parts inside every brushless drone motor: the stator and the rotor. The stator stays fixed in place and creates the magnetic field that drives the motor. The rotor spins and delivers the mechanical power needed for flight.

Stator Components:

- Metal coils made of copper wire, protected by enamel coating, prevent short circuits and boost durability.

- Laminated silicon steel sheets form the iron core, reducing magnetic flux loss and improving efficiency.

- Windings arranged in a three-phase configuration determine torque and speed. Wire gauge and winding count play a key role.

- Some motors use silver-plated copper wires for better electrical and thermal conductivity, though these cost more.

- Cooling structures, such as fans or thermal conductive materials, help manage heat during operation.

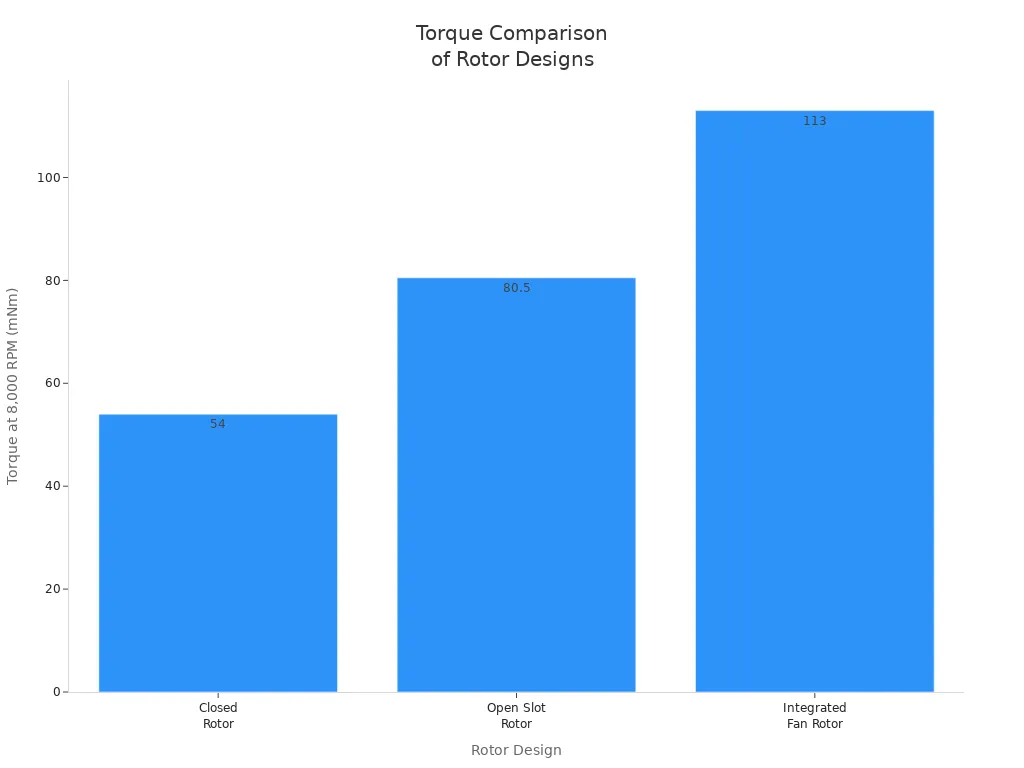

The rotor contains permanent magnets and rotates inside the stator’s magnetic field. Rotor design affects how much torque and power your drone receives. You can compare different rotor designs using the table below:

| Rotor Design | Torque at 8,000 RPM (mNm) | Torque Increase (%) | Thermal Resistance Behavior with Speed | Heat Dissipation Property | Power Rating |

|---|---|---|---|---|---|

| Closed Rotor | 54 | Baseline | Slight decrease up to 3,000 RPM, then a drastic increase beyond 5,000 RPM | Lowest heat dissipation | Lowest power rating |

| Open Slot Rotor | 80.5 | ~47% increase | Rapid decrease with speed | Moderate heat dissipation | Medium power rating |

| Integrated Fan Rotor | 113 | 40% higher than the open slot rotor | Rapid decrease with speed | Highest heat dissipation due to fan circulation | Highest power rating |

Tip: If you want maximum torque and efficient cooling, choose a brushless drone motor with an integrated fan rotor. This design supports higher speeds and power ratings, making it ideal for demanding drone applications.

How It Works

You control a brushless drone motor using an electronic speed controller (ESC). The ESC acts as the brain, sending precise electrical signals to the motor. Here’s how the process works:

- The stator contains copper windings, while the rotor holds permanent magnets.

- The ESC converts direct current (DC) from the battery into three-phase alternating current (AC) for the motor.

- The ESC switches current in the stator windings, creating a rotating magnetic field.

- This magnetic field causes the rotor to spin, turning electrical energy into mechanical motion.

- The ESC adjusts voltage and current to control speed and direction, enabling smooth acceleration and stable flight.

- Advanced ESCs use field-oriented control and sensorless algorithms to estimate rotor position and optimize current flow.

- Features like active braking and regenerative braking improve control precision and extend flight time.

Note: Matching the ESC’s current rating and features with your motor and flight controller ensures safe, efficient, and optimized drone performance.

You benefit from this system because it eliminates friction and wear found in brushed motors. The result is a brushless drone motor that delivers reliable power, smooth operation, and a longer lifespan.

Efficiency and Performance

Energy Conversion

You rely on a brushless drone motor to convert electrical energy from your battery into mechanical power with impressive efficiency. The motor uses electronic commutation and Hall sensors to achieve zero-contact energy transfer. This design reduces friction and heat loss, so you get more usable power for flight. Most brushless motors reach energy conversion efficiencies between 70% and 90%. In many cases, you see efficiency levels exceeding 90%, which is much higher than combustion engines. Even under light loads, these motors maintain over 80% efficiency. You benefit from this high efficiency because less energy is wasted as heat, and more is available for thrust and maneuverability.

Tip: High efficiency means your drone can fly longer and perform better, especially during demanding missions.

Flight Time Impact

Motor efficiency directly affects how long your drone stays in the air. Efficient motors draw less current, which helps you get the most out of your battery. You notice longer flight times when your drone uses motors with optimized magnets and wider air gaps, like those found in DJI models. Propeller design also plays a key role. Longer blades with low pitch improve efficiency and extend flight duration, while more blades or higher pitch reduce efficiency. Larger propellers generally increase flight time by minimizing drag and maximizing thrust.

- Efficient motors convert battery power into mechanical energy with minimal losses.

- Well-designed propellers reduce energy consumption.

- Regular maintenance preserves motor and propeller efficiency.

- Upgrading to advanced motors and propellers improves flight duration.

- Balanced weight distribution and lighter payloads lessen motor strain.

- High-quality batteries support longer flights.

- Fine-tuning motor calibration and propeller adjustments optimizes power usage.

- Proper battery care ensures sustained flight efficiency.

You see the best results when you combine efficient motors, smart propeller choices, and good battery management. Drones designed for endurance, such as those used for mapping or surveillance, benefit most from these optimizations.

Payload Capacity

The payload your drone can carry depends on the specifications of its brushless motors. Motors like the MAD 5010 EEE V2.0 deliver a peak burst thrust of 5.2 kg per motor. In a quadcopter setup, you can achieve up to 20.8 kg total thrust, supporting payloads of around 8 to 10 kilograms after accounting for the drone’s frame and battery weight. Commercial drones typically handle payloads between 9 and 30 kg, while heavy-lift models equipped with multiple brushless motors can reach capacities of 20 to 50 kg. Some industrial drones, especially those with hybrid or fuel-powered systems, carry even more.

Motor specifications, such as KV rating and propeller size, influence payload capacity. High KV motors like the Sparrow Series APM 6007-Kv320 offer fast speeds and efficiency for lightweight drones, making them ideal for racing or agile flight. These motors suit lighter payloads. In contrast, low KV motors paired with large propellers, such as the H140 KV80, generate significant torque and thrust. You use these setups for industrial drones that need to lift heavy equipment or supplies.

Note: Choose your motor and propeller combination based on your drone’s intended application. For heavy lifting, select low KV motors with large propellers. For speed and agility, opt for high KV motors with smaller propellers.

Brushless vs Brushed Motors

Key Differences

You notice several important differences when comparing brushless and brushed motors. Brushed motors use carbon brushes to deliver current to the rotor. This design causes friction, heat, and energy loss. Brushless motors rely on electronic commutation, which switches current without physical contact. You benefit from higher efficiency, stronger thrust, and longer flight times with brushless motors. The structure of a brushless drone motor is more advanced, resulting in lower maintenance and longer service life. Brushed motors have a simpler build and lower initial cost, but they wear out faster.

- Brushed motors use carbon brushes, causing friction and heat.

- Brushless motors use electronic commutation, eliminating friction.

- Brushless motors provide better efficiency and thrust.

- Brushed motors cost less but require more frequent replacement.

Reliability and Lifespan

Reliability plays a key role in drone performance. Brushed motors generate more heat and electrical noise due to friction between brushes and the commutator. This energy loss shortens battery life and reduces reliability. Brushless motors operate cooler and quieter, with less energy wasted as heat. You can expect a much longer lifespan from brushless motors. Brushed motors typically last about 6 hours of flight before the brushes wear down. Brushless motors often reach 10,000 to 20,000 hours under ideal conditions. In real-world drone use, brushless motors still outperform brushed motors by a wide margin.

| Motor Type | Average Lifespan (Hours) | Reliability in Commercial Use |

|---|---|---|

| Brushless Motor | 10,000 to 20,000 (ideal) | High reliability, preferred for drones |

| Brushed Motor | ~6 hours of flight | Lower reliability, frequent failures |

Tip: For commercial drones, you should choose brushless motors for their superior reliability and long operational life.

Maintenance

Maintenance requirements differ greatly between the two motor types. Brushed motors need regular brush and commutator replacement. You must monitor mechanical wear and electrical noise. Brushless motors eliminate these parts, so you only need to check bearings and prevent moisture or debris from entering the motor. Maintenance intervals for brushless motors are much longer, often exceeding 5,000 hours. Brushed motors require frequent servicing, sometimes every 500 to 1,000 hours. The absence of brushes in a brushless drone motor means less mechanical noise, lower wear, and minimal maintenance.

| Aspect | Brushless Motors | Brushed Motors |

|---|---|---|

| Maintenance Frequency | Minimal maintenance required | Regular maintenance needed |

| Key Maintenance Tasks | Inspect bearings, prevent moisture, and check for debris | Replace brushes, monitor wear, and noise |

| Mechanical Wear | Minimal due to no brushes or commutators | High due to brush and commutator wear |

| Lifespan | Longer | Shorter |

Note: Brushless motors save you time and money on maintenance, making them ideal for drones that demand precision and reliability.

Motor Selection for Drones

KV Ratings

Selecting the right KV rating is crucial for your drone’s performance. KV stands for “RPM per volt,” which tells you how fast the motor spins when you apply one volt with no load. For example, a 2300 KV motor on a 14.8V battery can reach up to 34,040 RPM. High KV motors spin faster but produce less torque, making them ideal for racing drones. Low KV motors spin slower but generate more torque, which helps lift heavier payloads.

| Aspect | Explanation |

|---|---|

| Definition of KV | KV rating is RPM per volt, indicating how fast the motor spins per volt applied. |

| Speed vs KV | Higher KV = higher RPM (speed), suitable for racing drones with small props. Lower KV = lower RPM, higher torque, suitable for heavy drones with large props. |

| Torque vs KV | Higher KV motors produce less torque due to fewer windings; lower KV motors produce more torque with more windings. |

| Propeller Size | High KV motors work best with small, light propellers to avoid overheating. Low KV motors are paired with large propellers for efficient thrust. |

| Battery Voltage | Must be matched with KV to optimize performance and avoid motor damage. Higher voltage with low KV prevents excessive RPM. Lower voltage with high KV compensates for speed. |

| Practical Impact | Selecting the correct KV rating balances speed, torque, and efficiency, ensuring stable and efficient drone operation. |

Tip: Always match your motor’s KV rating with the right propeller and battery to avoid overheating and get the best flight results.

Voltage and Size

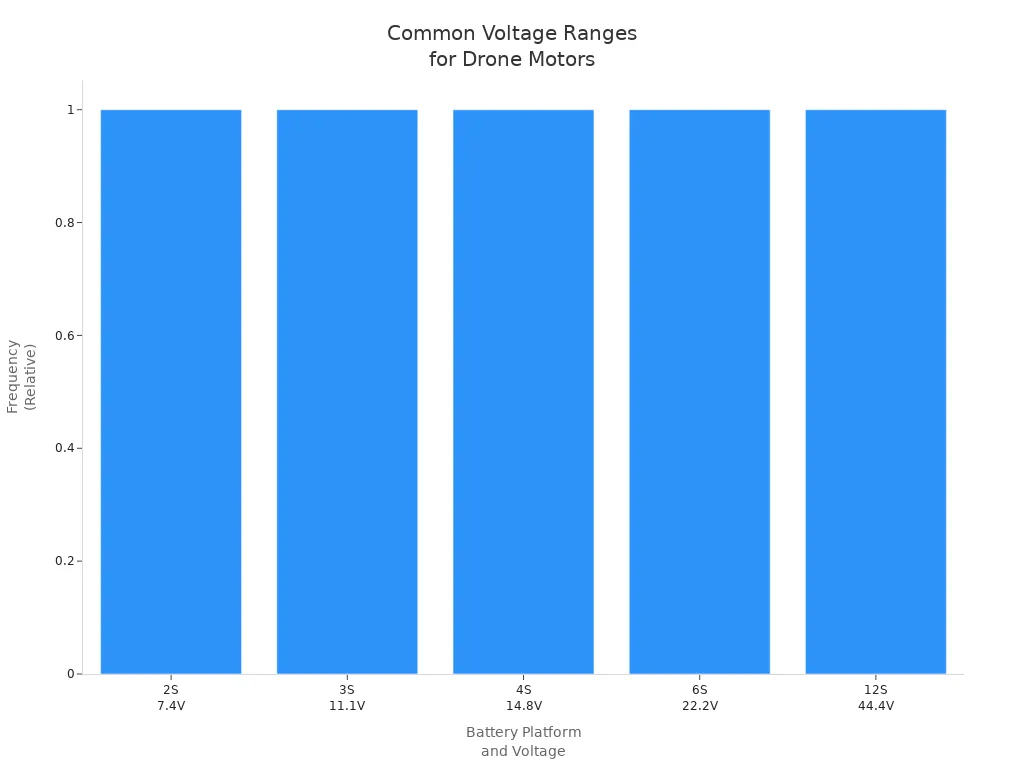

You must consider both voltage and motor size when choosing a motor. Most consumer drones use batteries from 2S (7.4V) to 6S (22.2V). Higher voltage systems, such as 12S (44.4V), are common in industrial drones. Matching the battery voltage with the motor’s KV rating ensures safe operation and prevents damage.

Motor size also affects performance. Larger motors provide more torque and can spin bigger propellers, which is essential for lifting heavy loads. However, bigger motors add weight and use more power, which can reduce flight time. Smaller motors are lighter and spin faster, making them perfect for racing or acrobatic drones.

| Battery Platform | Voltage Range (V) | Typical KV Range | Common Motor Sizes / Applications |

|---|---|---|---|

| 2S | 7.4 | 3000–5000KV | Small FPV drones (1104/1306) |

| 3S | 11.1 | 1600–3200KV | Leisure flying, micro FPV (1806/2205) |

| 4S | 14.8 | 900–2800KV | 5-inch racing, aerial photography (2306/2207/2212) |

| 6S | 22.2 | 400–1900KV | Racing, heavy-lift, industrial (2207/2306/3510) |

| 12S | 44.4 | 280–450KV | Large-scale, eVTOL, inspection |

Application Suitability

You should always match your motor choice to your drone’s purpose:

- Racing Drones: Use high KV motors (above 2000KV) and small, lightweight motors like 2204. These spin fast and respond quickly, giving you speed and agility.

- Heavy-Lift and Professional UAVs: Choose low KV motors (60–900KV) with larger stators. These provide high torque for lifting heavy payloads, such as in delivery or agricultural drones. A thrust-to-weight ratio of at least 3:1 is recommended for safe lifting.

- Photography and Survey Drones: Select mid-range KV motors (800–1200KV) with medium-sized propellers. This setup balances stability, efficiency, and flight time for smooth aerial shots.

Note: Always test your motor and propeller combination to ensure your drone meets your performance goals. Proper selection improves efficiency, flight time, and safety.

Advantages and Disadvantages

Pros

You gain several important benefits when you choose brushless motors for your drone:

- Higher energy efficiency means you get more flight time from each battery charge. The design eliminates friction from brushes, so more power turns into thrust.

- Longer operational life comes from less wear and tear. No brushes means fewer parts that can break down.

- Maintenance needs drop significantly. You spend less time and money on repairs, which keeps your drone in the air longer.

- Quieter and smoother operation helps you capture better audio and video. This also makes your drone less disruptive in sensitive environments.

- Compact and lightweight builds become possible. Brushless motors deliver more power in a smaller package, which supports advanced drone designs.

- Recent advances, like sensorless motor drives, reduce manufacturing costs and make these motors more affordable over time.

- Improved reliability and precise control support demanding commercial and professional applications.

Tip: If you want a drone that lasts longer, flies farther, and needs less upkeep, brushless motors offer the best value for most users.

Cons

You should also consider some drawbacks before making your decision:

- Brushless motors cost more upfront than brushed motors. The complex construction and need for electronic speed controllers (ESCs) increase the initial investment.

- Installation and wiring are more complicated. You must connect each motor to an ESC, which requires more technical skill.

- These motors may not suit low-cost or entry-level drones. For beginners or budget-conscious users, brushed motors remain a popular choice.

- The higher initial price can be a barrier for hobbyists or those building simple drones.

- Some repairs or replacements may require specialized knowledge or tools, especially if you use advanced features.

| Aspect | Brushless Motors | Brushed Motors |

|---|---|---|

| Initial Cost | Higher | Lower |

| Installation | More complex | Simple |

| Maintenance | Minimal | Frequent |

| Suitability | Professional, commercial | Entry-level, hobbyist |

Note: While brushless motors offer better long-term value, you should weigh the upfront cost and complexity against your specific needs and experience level.

You gain significant benefits when you choose the right motor for your drone. Brushless motors deliver higher speeds, better efficiency, and longer service life than brushed motors. You also enjoy quieter flights and less maintenance. The table below highlights these differences:

| Performance Aspect | Brushed Motors | Brushless Motors |

|---|---|---|

| Speed and Acceleration | Lower, due to friction | Higher, minimal friction |

| Efficiency | More energy is lost as heat | More power converted to thrust |

| Service Life | Shorter brushes wear out | Longer, fewer parts to wear out |

| Maintenance | Frequent brush replacement | Virtually maintenance-free |

| Noise | Noisier, brush contact | Quieter, less electrical noise |

When you select motors, consider structure, efficiency, and matching components. These choices improve reliability, flight time, and safety for every mission.

FAQ

What does the KV rating mean for a brushless drone motor?

KV rating tells you how many revolutions per minute (RPM) the motor spins for each volt you apply. Higher KV means faster spinning but less torque. Lower KV gives you more torque for lifting heavier payloads.

How do you maintain a brushless drone motor?

You should check the bearings for smooth rotation and keep the motor free from dust and moisture. Lubricate the bearings if needed. Avoid letting debris enter the motor. Regular inspection helps you catch issues early.

Can you use any ESC with a brushless drone motor?

Always match your ESC’s current rating and voltage range with your motor’s specifications. Using the wrong ESC can cause overheating or damage. Check the manufacturer’s recommendations before connecting components.

Why do brushless motors last longer than brushed motors?

Brushless motors have no brushes to wear out. You get less friction and heat, which means fewer parts fail over time. This design gives you a much longer operational life and reduces the need for frequent repairs.