Introduction to Multirotor Motors

This guide is designed for drone enthusiasts, builders, and professionals who want to understand how to select the best multirotor motors for their specific needs. Choosing the right motor is crucial for achieving desired flight performance, efficiency, and reliability. Multirotor motors play a vital role in drones, influencing their power, speed, and efficiency. These motors have become increasingly popular in aerial photography and racing. For example, a drone with three motors is called a tricopter, while one with four motors is known as a quadcopter.

Most multirotor drones use brushless outrunner motors because of their efficiency, durability, and high torque output. Specifically, Brushless DC (BLDC) motors are the standard choice, offering clear advantages over traditional brushed motors.

The frame holds the motors and other components, and its design—whether ‘X’ or ‘Y’ shaped—affects flight performance and how components are arranged. The motor and propeller layout define the drone’s configuration, which impacts stability and overall performance.

Understanding motor basics is key to choosing the right motor for your drone’s purpose, whether it’s a fixed-wing or multirotor type. One critical metric is the thrust-to-weight ratio (TWR), which is the ratio of maximum thrust to total drone weight and helps assess maneuverability.

Motor size and type have a big impact on drone performance and cost. Larger motors generally provide more thrust but add weight and expense.

Typically, the first two digits of a motor’s name indicate its size, which helps determine if it fits a particular aircraft.

Motor Fundamentals and Types

There are different motor types, with brushless motors being the go-to choice for multirotors due to their excellent power-to-weight ratio and efficient internal cooling fans. Outrunner motors have magnets on the outer casing and spin around a stationary inner core, delivering high torque at lower RPMs—ideal for driving large propellers efficiently. Inrunner motors, which have the rotor inside the stator, achieve very high RPMs but lower torque and are less common in multirotors.

Key motor specs like KV rating, voltage, resistance (measured in ohms), and weight influence efficiency and performance. The stator in an outrunner BLDC motor consists of an iron core laminated from silicon steel sheets with copper coils wrapped around it, affecting torque and speed. The rotor usually contains high-performance permanent magnets, often neodymium iron boron (NdFeB). High-quality motors utilize heat-resistant N52H or superior magnets, featuring minimal air gaps to ensure strong magnetic fields and optimal efficiency.

Retek Motors is a trusted brand offering a range of high-quality multirotor motors for applications like racing and aerial photography. Ball bearings are standard in high-performance drone motors, reducing friction and ensuring precision.

The stator and rotor work together: the stator creates the magnetic field, and the rotor converts it into mechanical energy. Magnets and bearings are critical for reliable, efficient motor operation.

No-load current (Io) refers to the current a brushless motor draws at a given voltage without mechanical load, which helps evaluate efficiency. Motors face loads like prop strikes or side forces during use, which affect lifespan and mean time between failures (MTBF). Considering these loads is important when selecting motors.

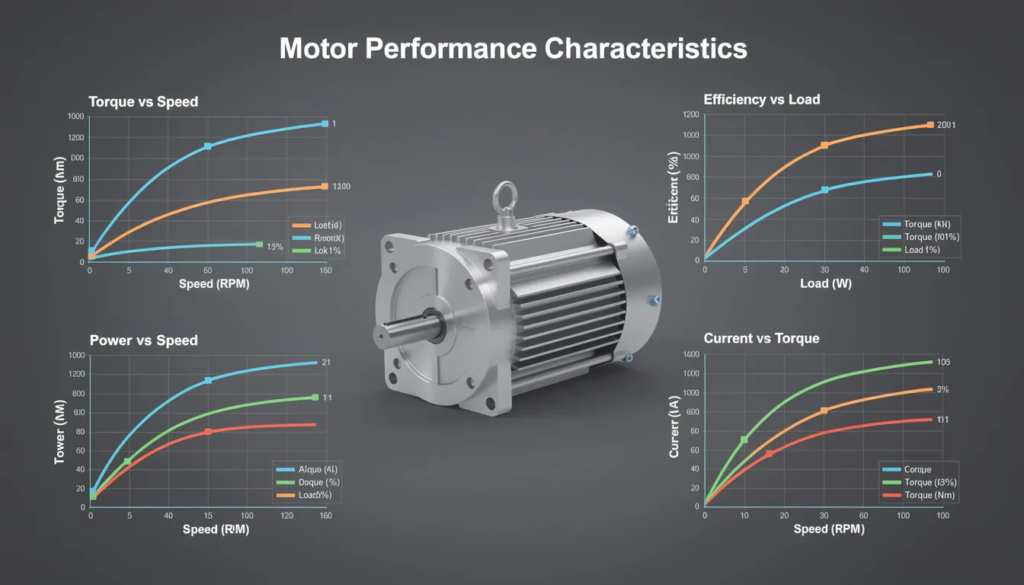

Motor Performance Characteristics

Motor performance is measured by thrust, efficiency, and power output. Efficient motors produce more thrust while consuming less power. Efficiency is commonly measured in grams per watt (g/W), indicating the effectiveness of converting electrical energy into thrust. Higher efficiency means longer flight times. Brushless motors excel here, offering longer flights and less maintenance by converting energy effectively.

KV rating indicates motor speed in RPM per volt; KV is defined as the increase in motor RPM for every 1 Volt increase in voltage, under no-load conditions. Higher KV means faster speeds.

Voltage and current affect power and thrust, but also increase risks of overheating and failure if not managed properly.

Thrust is the lift generated by the motor-propeller setup, and total thrust must exceed the drone’s weight for flight. The thrust-to-weight ratio (TWR) is crucial for maneuverability. For stable or cinematic flight, a TWR of 2:1 or 3:1 is typical, while racing drones often aim for 10:1 or higher to achieve extreme acceleration. A TWR around 2:1 is generally recommended for efficient hovering. To find the minimum thrust per motor, divide the total desired thrust by the number of motors, considering the drone’s weight and flight goals.

Propeller size and type also influence motor performance. Optimized props improve thrust efficiency and reduce motor overload risk.

Flight stability and maneuvering depend on precise motor speed adjustments. Multirotor drones control their motion by varying motor speeds, which is essential for balance and responsiveness.

Motor Size and Selection

Motor size is a key factor in choosing the right motor for your drone. Larger motors deliver more thrust but add weight and cost.

Motor size is usually denoted by a four-digit number representing the stator size, where the first two digits indicate the stator diameter in mm and the last two digits indicate the stator height in mm.

Choosing the right motor size involves considering payload, flight time, redundancy, and matching with the propeller and ESC. Using technical tables that list thrust, current, and efficiency for different motor and prop combos helps make informed decisions.

A stable, efficient motor depends on quality bearings, magnets, and internal cooling fans.

Motors should be replaced if you notice wear, damage, or performance drops to maintain safety and reliability. Replacement motors must match the system’s KV rating, voltage, and weight requirements.

Motor Applications

Motors serve various purposes like racing, freestyle flying, aerial photography, endurance, heavy-lift, and indoor flying, each needing specific motor traits.

Racing drones demand motors with high burst power and durability to handle high speeds and impacts, often using sizes like 2207 or 2306 with KV ratings between 1700 and 1950KV for 6S batteries. Racing drones must navigate sharp turns and obstacles quickly. Some racing setups push TWR beyond 10:1, turning drones into rockets with extreme vertical acceleration.

Aerial photography drones prefer low-KV motors paired with large propellers (800-1500KV) for smooth, vibration-free flight.

Long-endurance drones focus on efficiency, using low-KV motors around 1300KV for 7″ props to maximize flight time.

Heavy-lift drones need large motors with ultra-low KV (under 200KV) to drive big props, providing massive thrust and safety.

Indoor flying requires ultra-light, low-noise motors with very high KV (8,000-20,000+KV) to generate enough thrust with small props for safe maneuvering.

Fixed-wing aircraft also use motors, but have different requirements compared to multirotors.

Motor KV and voltage greatly influence suitability for each application.

Payload and flight time are critical; motors must provide enough thrust and efficiency for the load and desired duration.

Redundancy matters too—more motors add reliability and safety if one fails.

For custom motor sizes, KV ratings, or voltages, Retek Motors offers consultation and tailored solutions.

Motor and ESC Compatibility

- ESCs control motor speed and direction, so compatibility is essential.

- Timing and air gap between motor and ESC affect performance and efficiency. Optimized timing and air gap improve operation.Theg KV rating, voltage, current, propeller, and battery specs ensure smooth, reliable performance.

- Use example calculations to determine the right ESC based on motor size, prop, and battery.

- Incompatible motor-ESC pairs reduce efficiency and reliability and increase overheating and failure risk.

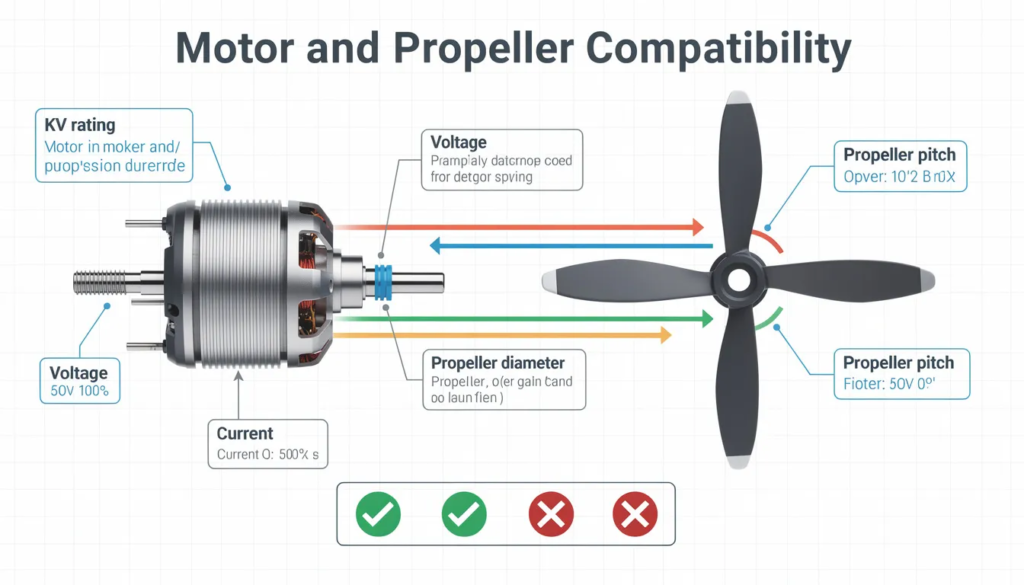

Motor and Propeller Compatibility

The propeller converts motor rotation into thrust, so motor-prop compatibility is critical. Multirotor motors are categorized by KV rating, indicating RPM increase per volt with no load.

Prop size and type affect motor performance and efficiency. Optimized props boost thrust and reduce overload risk. Matching prop size and pitch to the motor is crucial; mismatches can cause overheating or inefficiency.

High-KV motors suit small diameter, low-pitch props, delivering quick response and strong acceleration. Low-KV motors offer lower RPM with higher torque, ideal for larger, more efficient props.

Changing prop size also changes motor characteristics like KV and voltage requirements. Larger props produce more thrust but increase overload risk.

A compatible motor and prop improve performance, efficiency, reliability, and reduce failure risk.

Reliable operation depends on motor size, prop size, ESC type, battery, and aircraft type.

Motor and Battery Compatibility

Proper motor-battery matching is key for performance and safety. Motor KV, power use, and voltage must align with battery voltage, capacity, and discharge rate.

High-KV brushless motors, common in racing drones, need batteries that can supply high current at lower voltages to avoid overheating.

Low-KV motors handle higher voltage batteries better, preferred in aerial photography and freestyle drones for longer flights and stable power.

Retek Motors offers motors with varied KV ratings, so selecting the right battery is important.

Consider your drone’s use—racing, camera work, freestyle—to pick batteries matching motor specs.

Matching battery voltage and discharge rate to motor power needs ensures reliability, efficiency, and protects components.

Assessing Motor Quality

Evaluating motor quality is essential for building reliable drones. Top motors use advanced materials like heat-resistant magnets and precision bearings, enhancing performance and lifespan. Internal cooling fans are valuable, especially in racing motors, to dissipate heat and maintain efficiency.

Stator design, shaft smoothness, and bearing durability all affect motor performance. Features like curved magnets and improved winding techniques boost efficiency and power.

Brands like Retek Motors, T-Motor, EMAX, and iFlight have strong reputations for quality and innovation, offering reliable motors for racing and general use. When choosing a motor, consider both specs and brand reputation.

Motor Maintenance and Repair

Regular maintenance keeps motors running smoothly and extends their life. Tasks include:

- Inspect and clean bearings

- Clean shafts

- Clean stators

- Remove dust and debris that cause wear or reduce efficiency

Watch for wear signs like unusual noises or performance drops to catch problems early.

Repairs like replacing bearings or fixing stators require skill and tools. For example, rewinding a stator or straightening a bent shaft demands precision to avoid further damage.

Also consider replacement part availability and cost. Retek Motors provides support and maintenance guides to help users.

Proper maintenance and quality parts ensure consistent motor performance and reliability.

Emerging Trends and Technologies

Multirotor motor technology keeps evolving. Advances in materials and design have improved efficiency and power. Internal cooling fans are now common, boosting performance and reliability, especially in demanding uses.

Fixed-wing drones have driven the development of specialized motors suited to their needs.

Integration of AI and machine learning is enhancing drone autonomy, improving navigation, and obstacle avoidance.

Leading brands like Retek Motors, T-Motor, EMAX, and iFlight push innovation with more efficient, powerful, and reliable motors.

I’ve seen this fail when people ignore proper motor and ESC matching, so staying updated with technology and best practices is vital.

As the industry advances, expect more innovative propulsion and power solutions, making drones more capable and versatile than ever before.