Introduction to Motors for Drones

Motors for drones are fundamental components that significantly influence the overall performance, flight stability, and payload capacity of unmanned aerial vehicles (UAVs). These electric motors convert electrical energy into mechanical energy, enabling drones to generate lift, maneuver with precision, and achieve desired speeds. In the context of modern drones—ranging from aerial photography and industrial inspections to delivery drones—the choice of motor technology is critical for ensuring optimal performance and reliability. Motor size is indicated by a four-digit code, where the first two digits represent the stator’s diameter and the last two represent its height in millimeters. Whether you are a hobbyist or a professional in the drone industry, understanding the different types of drone motors and their key specifications is essential for selecting the right motor that meets your UAV application requirements.

Types of Drone Motors: Brushed vs. Brushless

Drone motors generally fall into two main categories: brushed motors and brushless motors. Brushed motors operate using carbon brushes that conduct current between stationary wires and the rotating armature. While these motors were traditionally used in smaller or less demanding UAV applications, they come with notable drawbacks such as lower motor efficiency, shorter motor lifespan, and increased maintenance due to brush wear and tear. Coreless motors are a notable variation of the brushed motor used in smaller drones.

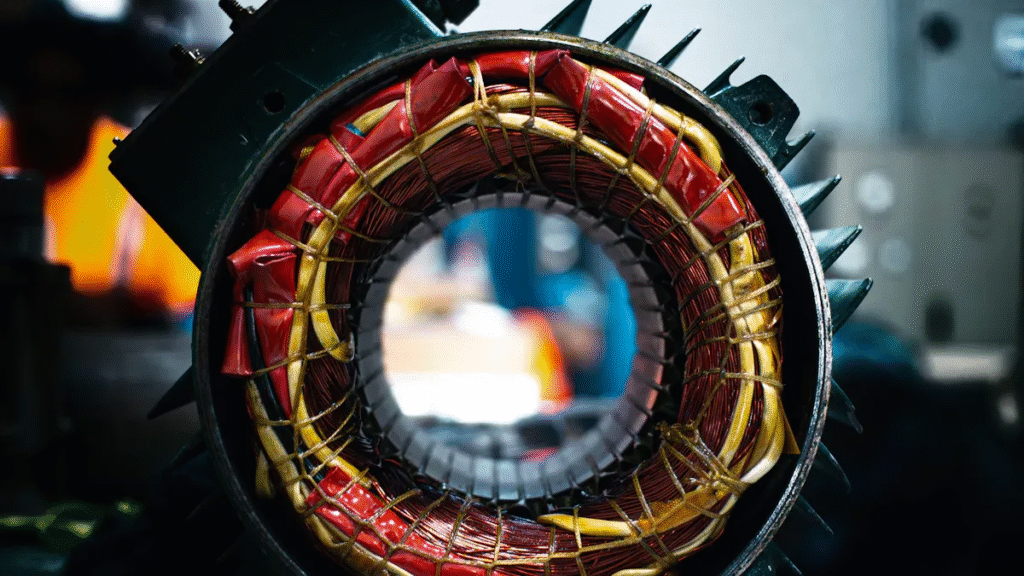

On the other hand, brushless DC motors (BLDC motors or BLDC motors) have become the industry standard for modern drones. Unlike brushed motors, brushless motors utilize a rotating magnetic field generated by electronic speed controllers (ESCs), eliminating the need for carbon brushes. Brushless motors have a stator with copper windings and a rotor with permanent magnets, eliminating the use of brushes. This design not only ensures zero vibration operation but also delivers higher efficiency and a longer motor lifespan. Brushless motors provide more torque and greater power output, making them ideal for high-performance drones, including heavy lift drones that require substantial thrust to carry heavier payloads.

Key Specifications of Drone Motors

Selecting the right motors for drones involves carefully considering several key specifications to guarantee sufficient power and optimal performance. The motor’s design encompasses critical factors such as power rating, voltage range, and kv rating, all of which directly affect motor speed and torque. The kv rating indicates how many revolutions per minute (rpm) the motor will turn per volt applied, serving as a guide to whether a motor is classified as a low-kv motor or a high-kv motor. The KV rating indicates how many revolutions per minute a motor will turn per volt of electricity without any load.

Low-kV motors typically generate greater torque and are well-suited for applications demanding more lift and heavier payloads, such as delivery drones and heavy lift drones. In contrast, high-kV motors provide higher speed and are favored in racing drones where rapid acceleration and precise control are paramount. Higher KV motors typically produce less torque than lower KV motors for the same current.

Other important considerations include motor efficiency, power output, and the motor’s ability to maintain stable flight in extreme weather conditions or harsh environments. Advanced cooling systems integrated into modern motor technology help manage heat dissipation, preserving the motor’s performance characteristics and preventing degradation in extreme temperatures. Integrated cooling systems within motors enhance performance during operations involving heavy lifting or demanding tasks. Propeller compatibility and size also play a vital role, as matching the right propeller to the motor’s power output and torque ensures maximum thrust and efficiency.

Motor Technology Advancements

Recent advancements in drone motor technology have led to the creation of powerful motors characterized by high power density and increased efficiency. Modern brushless DC motors, combined with sophisticated electronic speed controllers, offer precise regulation of motor speed, which enhances flight stability and overall drone performance. Brushless motors utilize an electronic speed controller (ESC) to switch current to the stator windings, creating a rotating magnetic field that spins the rotor. The smooth acceleration and deceleration enabled by ESCs contribute to stable flight and improved battery life, essential for extending flight times during UAV operations.

Innovations such as advanced cooling systems and optimized magnetic field designs have further boosted motor efficiency and durability. These technological improvements allow drone motors to operate reliably in challenging environments, including industrial inspections and vertical takeoff and landing (VTOL) aircraft applications, where consistent and exceptional performance is crucial. Environmental protection features in motors reduce the impact of sand, dust, and humidity on UAV operations.

Applications of Drone Motors in Various UAVs

Different UAV applications necessitate specific motor characteristics to fulfill their operational demands. Heavy lift motors are engineered to carry heavier payloads, making them indispensable for delivery drones and industrial drones used in aerial photography or inspections. These motors provide greater thrust and high torque to support increased payload capacity without sacrificing flight times. For a drone designed to lift heavy payloads, motors should ideally lift about 2.5 times the weight of the payload for good control and safety.

Fixed-wing drones, which require sustained high power for extended flight durations, benefit from motors optimized for high efficiency and stable power output. Racing drones, in contrast, prioritize high-kV motors that deliver high speed and rapid maneuverability. The motor’s design in racing drones focuses on achieving exceptional performance characteristics and precise control to navigate competitive environments effectively. Electric ducted fan motors are commonly seen in heavy lift applications due to their efficiency and compact size.

Optimizing Drone Performance with the Right Motor

Optimizing drone performance hinges on selecting the right motor by balancing key specifications such as power rating, kv rating, and voltage range with propeller compatibility. The size and type of propeller must correspond to the motor’s power output and torque to maximize thrust and efficiency. For example, pairing low-kV motors with larger propellers generates more lift and greater torque, which is essential for heavy lift applications.

Battery voltage, often supplied by LiPo batteries, directly influences motor speed and the overall power delivered to the drone. Ensuring that the motor’s voltage range aligns with the battery voltage is vital for achieving optimal performance and preventing damage to the motor or electronic speed controller. Additionally, understanding the motor’s power rating and how many revolutions the motor can achieve under specific voltage conditions helps in fine-tuning the UAV for maximum thrust and stable flight.

Conclusion

Motors for drones are the heart of UAV applications, directly impacting flight stability, payload capacity, and overall drone performance. The transition from brushed motors to brushless DC motors has revolutionized drone motor technology by offering higher efficiency, greater torque, and longer motor lifespan. By comprehending key factors such as motor speed, kv rating, power output, and motor specifications, drone enthusiasts and professionals can select the ideal motors tailored to their specific needs. Whether for heavy lift drones, racing drones, or delivery drones, leveraging advanced motor technology and ensuring proper motor-propeller pairing guarantees exceptional performance and reliable operation even in the most challenging environments.