When you choose a drone motor, you need to match the revolutions per minute (RPM) to your drone’s purpose. Racing drones often reach 30,000–50,000 RPM for high speed, while camera drones use moderate RPM for stability. Toy drones use low RPM, while professional models need powerful motors with lower RPM but higher torque. The right RPM depends on your drone’s size, weight, propeller, motor KV, and battery voltage. Matching RPM to your drone type improves both performance and safety.

| Drone Type | Typical RPM Range |

|---|---|

| Toy Drones | Low RPM |

| Racing Drones | 30,000–50,000 |

| Camera (Aerial) Drones | Moderate RPM |

| Professional/Industrial | Lower RPM, High Torque |

Retek Motion delivers quality drone motors and expert guidance for every application.

Key Takeaways

- Choose the right motor RPM based on your drone’s type, size, and purpose to ensure safe and efficient flight.

- Use the formula RPM = KV × Voltage to estimate motor speed, but always check actual loaded RPM for accuracy.

- Match motor KV, battery voltage, and propeller size carefully to balance speed, thrust, and motor health.

- Higher RPM increases thrust but also raises heat and power demands; avoid mismatches to prevent damage.

- Test your drone setup on the ground and adjust based on flight data to optimize performance and reliability.

RPM and Drone Motor Basics

What Is RPM

Revolutions per minute (RPM) measures how fast the shaft of a drone motor spins. You can think of RPM as the number of complete turns the motor makes in one minute. This value connects directly to the motor’s KV rating. For example, if you use a motor with a KV rating of 1000 and supply it with 1 volt, the shaft will spin at 1000 RPM. The actual RPM depends on both the voltage you provide and the design of the motor. When you increase the voltage, you increase the RPM. The KV rating also affects the balance between speed and torque, which plays a key role in how your drone performs.

Brushless outrunner motors have become the standard for drones. These motors offer high torque, excellent efficiency (often between 80% and 95%), and long lifespans. They achieve higher RPMs and reduce heat by eliminating brushes, which means less friction and better thermal management. This technology supports a wide range of drone sizes and applications, from small toys to heavy-duty industrial models.

Why RPM Matters

RPM is not just a number—it shapes how your drone flies. The speed at which your drone motor spins determines how much thrust and lift your drone can generate. Engineering research shows that:

- RPM depends on the motor’s KV rating and the battery voltage.

- Thrust increases rapidly as RPM rises. If you double the RPM, you get about four times more thrust.

- High RPM under load requires enough power from your battery and motor.

- These principles come from real-world motor testing and align with core engineering concepts.

Recent advances in magnet materials, such as improved neodymium-iron-boron alloys, have boosted motor power and efficiency. Better thermal management and lighter motors help your drone fly longer and handle higher speeds. Some new motors even use smart magnets with sensors for real-time monitoring, making your drone safer and more reliable.

Choosing the right RPM for your drone motor ensures you get the performance, efficiency, and reliability you need for your specific drone type.

Factors Affecting Drone Motor RPM

Drone Type and Size

The type and size of your drone play a major role in determining the ideal RPM for your motors.

- Small racing drones need very high RPM motors, often reaching 30,000–50,000 RPM. These require specialized miniature bearings that can handle extreme speeds and reduce overheating.

- Medium-sized drones use lighter, thin-section bearings to balance weight and load, supporting moderate RPMs.

- Large drones or heavy-lift UAVs rely on robust bearings with higher load capacity, but these operate at lower RPMs due to their size.

- High-performance racing drones may use hybrid ceramic bearings to minimize friction and heat, allowing for higher RPMs and better efficiency.

Selecting the right bearing and motor combination for your drone type ensures smooth power delivery and prevents premature wear.

Weight and Payload

As you add more weight or payload to your drone, you increase the demand for thrust. The motors must spin faster to lift heavier loads. For example, if you attach a camera or cargo, the total weight rises, and your drone motor must generate more thrust by increasing RPM.

| Factor | Explanation | Impact on RPM and Stable Flight |

|---|---|---|

| Payload Weight | Extra equipment or cargo | Requires more thrust, so higher RPM |

| Total Weight | Drone plus payload | Demands higher RPM for lift |

| Thrust | Force from motors and propellers | Must exceed weight; increases with RPM |

| Motor Torque | Motor’s ability to maintain RPM under load | Higher torque needed for heavier payloads |

| Propeller Size & Pitch | Larger or higher-pitch props | Need more torque and RPM |

| Thrust-to-Weight Ratio | Total thrust divided by total weight | Must be >1; heavier drones need higher RPM |

When you place payloads below the drone, airflow can become disturbed, reducing thrust efficiency. Always consider both the weight and its position for stable flight.

Propeller Size and Pitch

Propeller size and pitch directly affect how fast your motors need to spin.

- Larger diameter propellers running at lower RPMs (around 1400–2200 RPM) are more efficient than smaller props at higher RPMs.

- Higher pitch and thicker blades at lower RPMs reduce noise and improve efficiency.

- Lower RPM props require more torque from the motor.

- The ideal pitch speed (pitch × RPM) for maximum efficiency is about 55–60 km/h at full throttle.

- Propeller design, including blade thickness and number of blades, also impacts performance and noise.

Choosing the right propeller helps you achieve the best balance between efficiency, thrust, and noise.

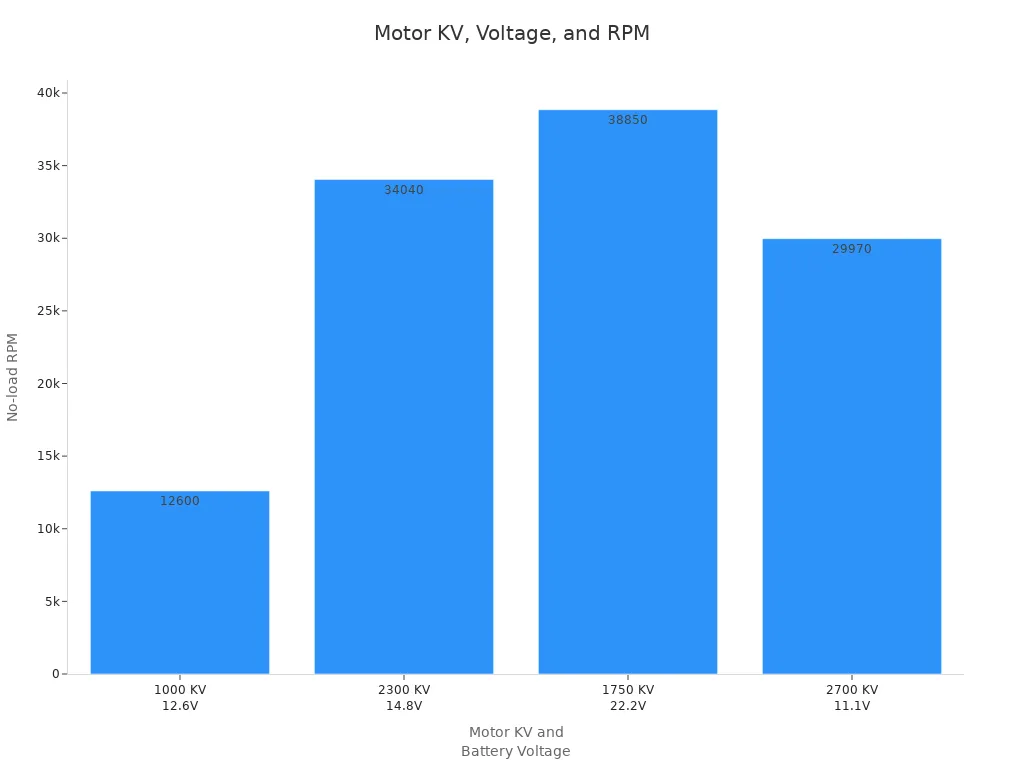

Motor KV Rating

The KV rating tells you how many revolutions per minute your motor will spin for each volt applied with no load. To estimate the no-load RPM, use the formula:

RPM = KV × Voltage

A high KV motor spins faster per volt but draws more current and generates more heat. For example, a 2300KV motor on a fully charged 3S battery (12.6V) will reach about 28,980 RPM (2300 × 12.6). However, when you attach a propeller, the actual RPM drops due to load.

| Motor KV | Battery Voltage (V) | No-load RPM (KV × V) |

|---|---|---|

| 1000 KV | 12.6V | 12,600 RPM |

| 2300 KV | 14.8V (4S) | 34,040 RPM |

| 1750 KV | 22.2V (6S) | 38,850 RPM |

| 2700 KV | 11.1V (3S) | 29,970 RPM |

Battery Voltage

Battery voltage sets the upper limit for your motor’s RPM. Higher voltage batteries allow your drone motor to spin faster, but only if the motor and propeller can handle the speed. Modern Lithium Polymer (LiPo) batteries provide high energy density and fast discharge rates, supporting reliable motor startup and sustained high RPMs. Advanced battery management systems monitor voltage and temperature, protecting both the battery and the motor. As battery technology improves, you gain more consistent and efficient performance at higher speeds.

Calculating the Right RPM

Step-by-Step Guide

To determine the ideal RPM for your drone, you need to follow a systematic approach. This process ensures that your drone motor delivers the right balance of thrust, efficiency, and safety for your specific application.

- Understand the RPM Formula

Use the basic formula:RPM = KV × VoltageKV represents the motor’s revolutions per minute per volt. Voltage refers to your battery’s output.

- Select Motor KV and Battery Voltage

Choose a motor KV rating and battery voltage that match your drone’s weight, flight style, and propeller size. Heavier drones benefit from lower KV motors with larger propellers. Racing drones require higher KV motors and smaller props for speed. - Evaluate Thrust-to-Weight Ratio

Calculate the thrust-to-weight ratio. For stable flight, aim for a ratio above 1:1. Racing drones often exceed 5:1, while camera drones may operate efficiently at 2:1 or 3:1. - Consider Propeller Characteristics

Larger diameter and lower pitch propellers need lower RPM for efficient thrust. Smaller, higher pitch props require higher RPM for agility. - Account for Loaded vs. No-Load RPM

The formula gives you the no-load RPM. In real-world conditions, the actual RPM drops due to propeller load. Use loaded KV values or measure RPM under load for accuracy. - Bench Test Your Setup

Use a motor thrust stand, wattmeter, and tachometer to measure thrust, current, temperature, and RPM with your chosen propeller and battery. - Perform a Pre-Flight Checklist

Inspect your motor and propeller, verify battery voltage, balance your propellers, and monitor current and temperature during operation. - Iterate and Optimize

Test different combinations of motors, propellers, and batteries. Adjust based on flight time, stability, and efficiency. - Monitor System Limits

Ensure your ESC and battery can handle the current draw at your target RPM. Avoid overheating or overloading components. - Fine-Tune Based on Flight Data

Adjust your setup after real-world flights. Use efficiency metrics and flight observations to achieve the best balance of thrust, power consumption, and motor longevity.

Tip: Always use loaded RPM values for more accurate predictions. Real-world propeller load reduces actual RPM compared to theoretical no-load RPM.

Example Calculations

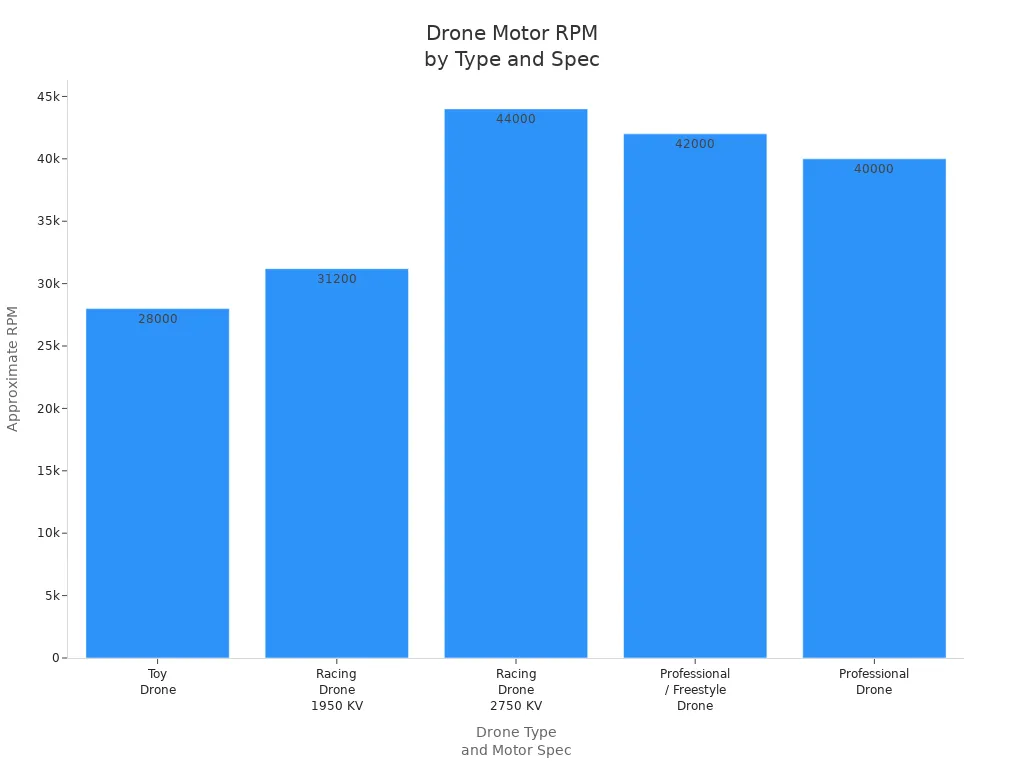

You can use the RPM formula to estimate the performance of different drone types. The following table shows real-world examples using actual motor KV ratings and battery voltages:

| Drone Type | Motor Model | KV Rating | Battery Voltage (V) | Propeller Size | Approx. RPM (KV × Voltage) | Thrust per Motor (kg) | Total Thrust (kg) | Thrust-to-Weight Ratio Example |

|---|---|---|---|---|---|---|---|---|

| Toy Drone | MEPS 2306 | 1750 KV | 16 (4S) | Smaller props | 1750 × 16 = 28,000 | ~0.85 | ~3.4 (4 motors) | Lower thrust, efficient flight |

| Racing Drone | MEPS 2207 | 1950 KV | 16 (4S) | 5 inch | 1950 × 16 = 31,200 | >1.0 | ~4.0 (4 motors) | ~6.7:1 (for 1 kg drone) |

| Racing Drone | MEPS 2207 | 2750 KV | 16 (4S) | 5 inch | 2750 × 16 = 44,000 | Higher thrust | Higher total thrust | Higher thrust-to-weight ratio |

| Professional / Freestyle Drone | MEPS 2207 | 1750 KV | 24 (6S) | 5 inch | 1750 × 24 = 42,000 | Efficient thrust | N/A | Longer flight efficiency |

| Professional Drone | MEPS 2408 | 2500 KV | 16 (4S) | 6 inch | 2500 × 16 = 40,000 | ~2.0 | N/A | Suitable for heavier payloads |

Note: Battery voltages correspond to LiPo cell counts. For example, 4S = ~16.8V fully charged, 6S = ~25.2V fully charged.

You can see that calculated RPM values align closely with recommended ranges for each drone type. For example, a toy drone with a 1750 KV motor and a 16V battery achieves about 28,000 RPM, which supports efficient, stable flight. Racing drones with higher KV motors and similar voltage can reach 44,000 RPM or more, delivering the speed and agility needed for competition. Professional drones often use lower KV motors with higher voltage batteries to achieve high thrust and efficiency at moderate RPM, supporting heavier payloads and longer flight times.

- Use the formula RPM = KV × Voltage to estimate your motor speed, but always verify with loaded RPM for accuracy.

- Select motor KV and battery voltage based on your drone’s weight and flight style.

- Adjust propeller size and pitch to match your target RPM and thrust requirements.

- Test your setup on the ground before flying to ensure all components work together safely.

By following these steps and calculations, you can optimize your drone motor selection for your specific needs, whether you fly for fun, race competitively, or capture professional aerial footage.

Common Issues and Solutions

High KV Problems

When you select a motor with a high KV rating, you may encounter several challenges. High KV motors spin propellers at greater speeds, which increases the demand for torque and draws more current from your battery. This extra current causes the motor to heat up quickly. If the motor overheats, the protective coating on the coils can break down, leading to electrical shorts or even complete motor failure. Using a high KV motor with a large propeller makes these problems worse, as the motor must work even harder. High KV motors also have lower resistance, which means they cannot handle high voltage as well and are more likely to overheat. You should always match your motor KV to your battery voltage and propeller size to avoid these issues.

- High current draw can shorten flight time and damage batteries.

- Overheating risks permanent damage to the motor and ESC.

- Large propellers with high KV motors increase the chance of failure.

Tip: Choose a motor KV that fits your drone’s size and purpose. Racing drones benefit from high KV, while larger drones need lower KV for stability.

Propeller Mismatches

Selecting the wrong propeller for your drone motor leads to poor performance and possible damage. Experts often see these mistakes:

- Pairing high KV motors with large propellers causes excessive current draw and overheating.

- Using small propellers with low KV motors results in weak thrust and sluggish flight.

- Ignoring the balance between propeller size, pitch, and motor KV reduces efficiency and flight time.

- Failing to match the propeller to the drone’s weight and purpose can cause unstable flights.

You should always match smaller propellers with high KV motors for speed and agility. Larger propellers work best with low KV motors, providing more torque for heavy payloads.

Efficiency and Overheating

Running your drone motor at high RPM and voltage increases both iron and copper losses inside the motor. This leads to rapid heat buildup, even if the motor is not under heavy load. Doubling the voltage can double the iron losses, pushing the motor closer to its thermal limits. High RPM can also cause the ESC to lose sync with the motor, especially if electrical noise or sudden speed changes occur. This desync can stall the motor or damage the ESC.

- Select ESCs that match your motor’s KV and commutation speed.

- Use low ESR capacitors to reduce electrical noise.

- Adjust firmware settings to improve ESC timing and prevent desync.

- Ensure your drone motor has proper cooling and is protected from dust and moisture, especially in agricultural or industrial drones.

Note: Always monitor motor temperature during flight. If you notice excessive heat, reduce RPM or improve cooling to protect your equipment.

Typical RPM Ranges by Drone Type

Selecting the right RPM range for your drone ensures optimal performance, safety, and efficiency. Each drone category has a distinct RPM range based on its design and intended use. Use the following guide to match your drone’s needs with the correct motor speed.

A quick reference table helps you compare RPM ranges at a glance, making it easier to choose the right motor and avoid issues like overheating or poor efficiency.

| Drone Type | Typical RPM Range | Application Focus |

|---|---|---|

| Toy Drones | 10,000 – 15,000 | Entry-level, indoor/outdoor fun |

| Racing Drones | 30,000 – 50,000+ | High-speed, agility, competition |

| Camera Drones | 10,350 – 41,400 | Stable flight, aerial imaging |

| Professional Drones | 20,000+ (often lower) | Heavy-lift, endurance, industry |

Toy Drones

You will find that toy drones typically operate between 10,000 and 15,000 RPM. Manufacturers design these motors to balance safety, efficiency, and ease of use. Many toy drones share technology with small racing models, using bearings rated for speeds up to 53,000 RPM. This high-speed capability ensures smooth operation, even during quick maneuvers.

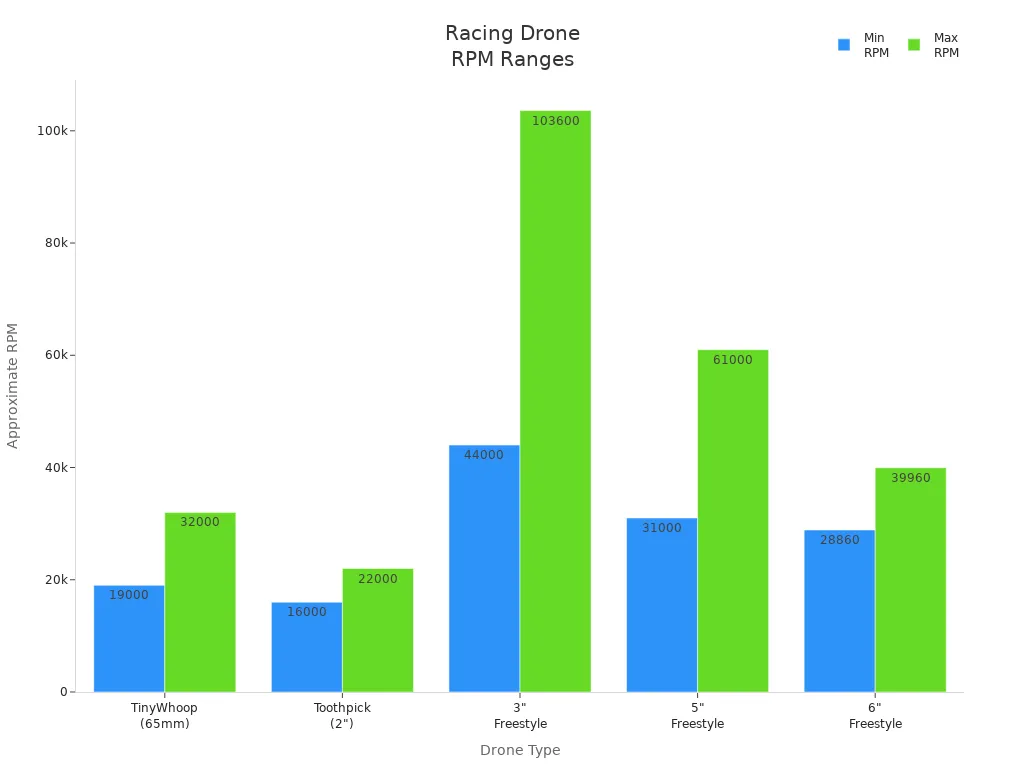

Racing Drones

Racing drones demand the highest RPMs, often reaching 30,000 to 50,000 RPM or more. For example, a 5-inch FPV racing drone with a 2500 KV motor and a 6S battery can achieve up to 55,500 RPM. This high speed delivers rapid acceleration and sharp turns, which are essential for competitive racing. The table below highlights how different racing drone classes compare:

| Racing Drone Class | Motor KV Range | Battery (S) | RPM Range |

|---|---|---|---|

| TinyWhoop (65mm) | 19,000–32,000 | 1S | 19,000–32,000 |

| Toothpick (2″) | 16,000–22,000 | 1S | 16,000–22,000 |

| 3″ Freestyle/Racing | 4,000–7,000 | 3S–4S | 44,000–103,600 |

| 5″ Freestyle/Racing | 2,100–2,750 | 4S–6S | 31,000–61,000 |

| 6″ Long Range | 1,300–1,800 | 6S | 28,860–39,960 |

Camera Drones

Camera drones usually run their motors at 10,350 to 41,400 RPM. This range provides enough thrust for stable flight while minimizing vibration and noise. Lower RPMs help you capture sharp images and smooth video by reducing jerky movements. Precision bearings in both the motors and gimbals further isolate the camera from vibrations, ensuring professional-quality aerial photography.

Professional Drones

Professional drones use lower KV motors with higher voltage batteries to achieve stable flight and carry heavy payloads. These motors often operate above 20,000 RPM, but the focus shifts to torque and efficiency rather than maximum speed. For heavy-lift or industrial applications, you benefit from lower RPMs paired with larger propellers, which provide the thrust needed for safe and reliable operation.

Tip: Always check your drone’s specifications and intended use before selecting a motor. Matching the RPM range to your application extends component life and improves flight performance.

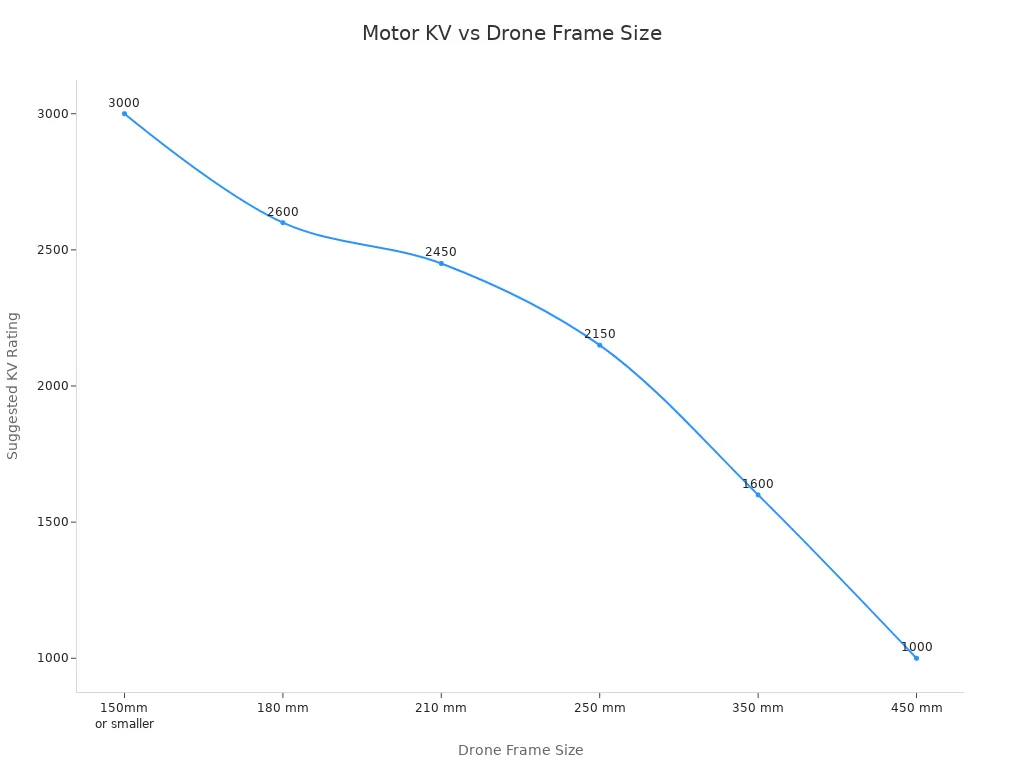

Choosing the right RPM for your drone ensures safe, efficient, and powerful flight. You should always match motor KV, propeller size, and battery voltage to your drone’s frame and purpose. Use calculation guides and reference tables to select the best setup for your needs. The table below shows how to pair frame size, propeller, and KV for optimal results:

| Frame Size | Propeller Size | Motor Size | KV Range |

|---|---|---|---|

| 150mm↓ | ≤3 inch | 1306↓ | 3000+ |

| 180mm | 4 inch | 1806 | ~2600 |

| 210mm | 5 inch | 2204–2206 | 2300–2600 |

| 250mm | 6 inch | 2204–2206 | 2000–2300 |

| 350mm | 7 inch | 2208 | ~1600 |

| 450mm | 8–10 inch | 2212+ | ≤1000 |

Retek Motion delivers certified quality, expert support, and a wide range of motors for every drone application. For deeper optimization, explore resources on motor matching, propeller testing, and tuning throttle response.