Drone Motor diameter limits define the range of motor sizes that fit a drone’s frame and propeller setup. Selecting the correct diameter ensures stable flight and efficient power delivery. For example, a 7-8mm motor typically pairs with a 1.2-1.6 inch propeller on a Tinywhoop, while a 20-24mm motor supports a 5-6 inch propeller for freestyle or racing drones. The right match prevents wasted energy, overheating, and poor performance.

Key Takeaways

- Choose a motor size that fits your drone’s frame and propeller to ensure stable flight and good performance.

- Larger motors provide more thrust and better cooling but add weight; smaller motors are lighter but may overheat under heavy use.

- Match the motor’s KV rating with the propeller size and battery voltage for efficient power use and longer flight times.

- Check your drone frame’s motor mounting pattern and recommended motor size before buying to avoid fit and vibration problems.

- Regularly inspect motors and propellers to prevent failures and keep your drone flying safely and reliably.

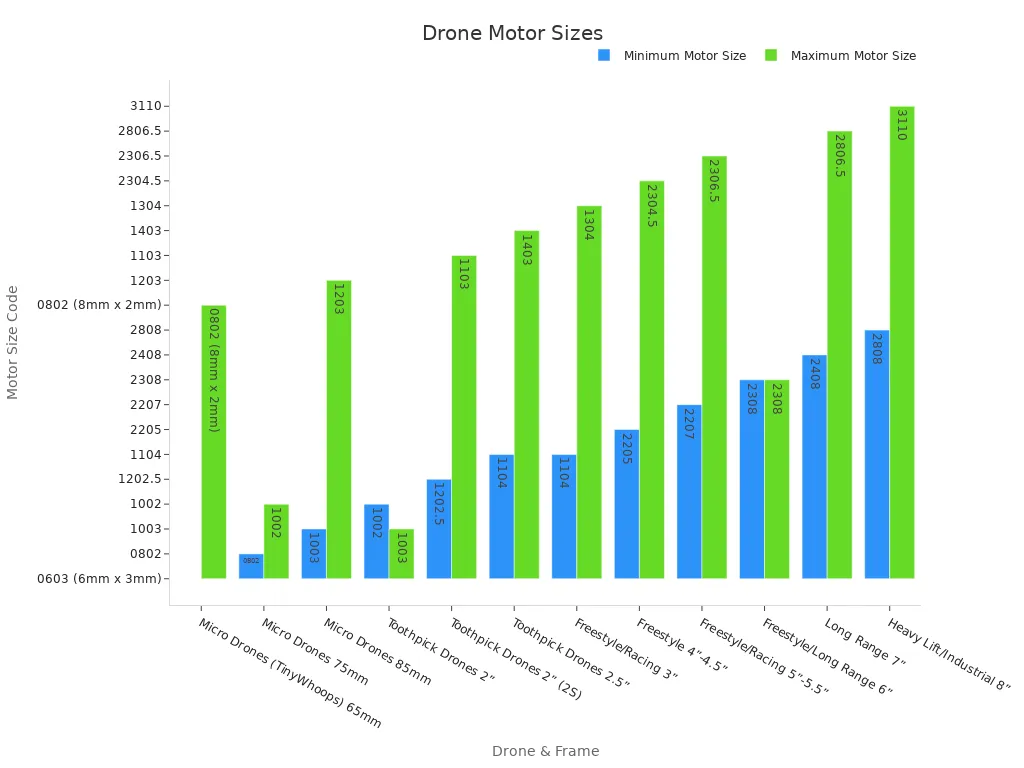

Drone Motor Diameter Limits

Minimum and Maximum Sizes

Frame size and propeller size set the practical boundaries for Drone Motor diameter. A motor that is too large for the frame will not fit or will add unnecessary weight, while a motor that is too small cannot deliver enough thrust for stable flight. Manufacturers use a four-digit code to describe motor size, such as 2207, where the first two digits represent the stator width in millimeters and the last two indicate the stator height. For example, a 2207 motor has a 22mm wide and 7mm tall stator.

The following table outlines the minimum and maximum motor sizes commonly used for different drone classes:

| Drone Class | Frame Size / Prop Size | Minimum Motor Size | Maximum Motor Size | Typical Use Case / Notes |

|---|---|---|---|---|

| Micro Drones (TinyWhoops) | 65mm | 0603 (6mm x 3mm) | 0802 (8mm x 2mm) | Indoor FPV, racing; 0603 for chunkier builds |

| Micro Drones | 75mm | 0802 | 1002 | Indoor/outdoor FPV; balance of power and efficiency |

| Micro Drones | 85mm | 1003 | 1203 | Outdoor capable ducted whoops; 2S battery compatible |

| Toothpick Drones | 2” | 1002 | 1003 | Lightweight outdoor freestyle/racing |

| Toothpick Drones | 2” (2S) | 1202.5 | 1103 | High-speed outdoor flying |

| Toothpick Drones | 2.5” | 1104 | 1403 | Powerful outdoor freestyle/racing; 2S-3S battery |

| Freestyle/Racing | 3” | 1104 | 1304 | High-performance freestyle and racing; 3S-4S battery |

| Freestyle | 4” – 4.5” | 2205 | 2304.5 | Light and agile freestyle FPV |

| Freestyle/Racing | 5” – 5.5” | 2207 | 2306.5 | Standard FPV drones; freestyle and racing |

| Freestyle/Long Range | 6” | 2308 | 2308 | Mid-range freestyle/cruising |

| Long Range | 7” | 2408 | 2806.5 | Long-range FPV, endurance flights |

| Heavy Lift/Industrial | 8” | 2808 | 3110 | Cinematic filming, mapping, industrial use |

Tip: Always check the frame’s motor mounting pattern before selecting a Drone Motor. A mismatch can lead to mounting issues or vibration problems.

The smallest motors, such as 0603, power micro drones for indoor racing. At the other end, industrial drones use motors as large as 3110 for heavy lifting and mapping. Most hobbyist drones fall between these extremes.

Typical Ranges by Drone Type

Different drone types require different motor diameters to achieve the right balance of thrust, efficiency, and durability. Micro drones, such as TinyWhoops, use motors between 6mm and 12mm in diameter. These small motors keep the drone lightweight and agile for indoor flight. Toothpick drones, designed for outdoor freestyle or racing, use motors from 10mm to 14mm. This range provides enough power for quick maneuvers without adding excess weight.

Freestyle and racing drones with 5-inch propellers typically use motors in the 22mm to 23mm diameter range, such as 2207 or 2306. These motors deliver high thrust and fast response, which are essential for acrobatic flight. Long-range drones and heavy-lift platforms require even larger motors, sometimes up to 31mm in diameter, to handle bigger propellers and heavier payloads.

Industrial drones can use motors larger than 31mm, but these are rare in consumer applications. Most drone builders select a Drone Motor that matches the frame and propeller size, ensuring the motor operates within its optimal range. Oversized motors may offer more power, but they also increase weight and reduce efficiency.

Note: The stator’s width and height both influence performance. Wider stators improve cooling and low-speed handling, while taller stators provide higher speed and better control at low RPM.

Selecting the right Drone Motor diameter involves understanding the drone’s intended use, frame size, and propeller requirements. By following these guidelines, builders can avoid common pitfalls and achieve reliable, efficient flight.

Performance Impact

Thrust and Efficiency

Motor diameter plays a key role in determining how much thrust a drone can generate and how efficiently it uses power. The thrust-to-power ratio measures how well a motor and propeller convert electrical energy into thrust. A higher ratio means the drone produces more thrust for each watt consumed, which improves flight time and performance.

Larger diameter motors often provide more torque. This allows them to spin bigger propellers at lower speeds, which increases efficiency and reduces battery drain. Heavy-lift drones use motors with large diameters and low KV ratings (below 400KV) to achieve stable, high thrust output. Aerial photography drones typically use moderate motor diameters and low KV values (300-500KV) to balance thrust and endurance. Racing drones, on the other hand, rely on smaller diameter motors with high KV ratings (above 600KV) for quick acceleration and agility, even if it means sacrificing some efficiency.

Tip: Matching the motor diameter to the propeller size and drone type helps optimize the thrust-to-power ratio, leading to longer flight times and better overall performance.

Heat and Durability

Motor diameter also affects how well a drone motor manages heat. Larger motors have more surface area and bigger windings, which help dissipate heat more effectively. This feature supports sustained thrust output and prevents overheating during demanding flights.

- Larger diameter motors improve efficiency and cooling, making them suitable for long-duration or heavy-lift flights.

- Smaller motors may heat up quickly under heavy loads, which can shorten their lifespan and reduce reliability.

Durability depends on both the motor’s ability to handle heat and the quality of its construction. Pilots who push their drones to the limit, such as racers or heavy-lift operators, benefit from motors with robust designs and effective cooling. Proper motor selection ensures the drone remains reliable, even during intense use.

Design Considerations

Frame and Mounting

Selecting the right motor diameter begins with the drone’s frame. Each frame supports a specific range of motor sizes, determined by the arm width, mounting hole pattern, and overall geometry. Designers often rely on scaling laws and dimensional analysis to estimate the optimal relationship between frame size and motor diameter. This approach assumes geometric similarity between components, allowing for regression models that guide early-stage decisions. While no single formula links frame dimensions directly to motor diameter, these frameworks help designers understand how changes in one parameter affect the others.

Mounting patterns play a crucial role in compatibility. Most frames specify a bolt circle diameter and hole spacing for motor installation. Choosing a motor that matches these specifications ensures a secure fit and reduces vibration. A mismatch can cause mechanical stress or even failure during flight. Cooling also depends on the frame’s design. Wider arms and open structures allow better airflow around the motor, helping dissipate heat during demanding flights.

Tip: Always verify the frame’s recommended motor size and mounting pattern before purchasing a Drone Motor. This step prevents costly mistakes and ensures a smooth build process.

Propeller Compatibility

Matching the motor diameter to the propeller size is essential for efficient and reliable performance. Engineering tests show that thrust and torque increase with propeller diameter and speed. However, beyond a certain point, larger propellers provide only marginal gains in thrust unless paired with a more powerful motor. If the motor cannot handle the increased load, it may overheat or suffer from mechanical resonance.

- Thrust increases with both propeller diameter and rotational speed.

- Torque rises sharply as propeller diameter grows, placing greater demands on the motor.

- Performance charts illustrate that each motor diameter has an optimal propeller size range.

Selecting the correct propeller involves more than just diameter. The pitch, blade count, and material also affect performance. Mechanical compatibility matters as well. The motor shaft must fit the propeller hub securely to avoid vibration and power loss. Designers should always match the motor’s power and diameter to the propeller’s requirements for safe and efficient operation.

KV and Battery Match

The KV rating of a motor describes how many revolutions per minute it produces per volt applied. This value must align with both the propeller size and the battery voltage. Different KV ratings suit different propeller sizes and pitches. A mismatch can waste power or overload the motor, leading to inefficiency or damage.

- Low KV motors pair well with large-diameter propellers and high-voltage batteries. These setups deliver high thrust at lower speeds, ideal for heavy-lift or endurance drones.

- High KV motors work best with smaller propellers and lower-voltage batteries. They provide rapid acceleration and agility, which suits racing drones.

Proper matching of KV, battery, and propeller size ensures the Drone Motor operates within its optimal range. This balance maximizes thrust-to-weight ratio, extends flight time, and improves reliability. Mechanical compatibility between the motor shaft and propeller hub also prevents vibration and inefficiency.

Note: Always consult manufacturer charts and test data when selecting a motor, propeller, and battery combination. This practice helps avoid common pitfalls and supports safe, high-performance drone builds.

Drone Motor and Propeller Matching

Sizing Guidelines

Selecting the right combination of motor and propeller ensures a drone operates efficiently and safely. Builders should consider payload, frame size, and flight goals when choosing components. The following ordered list provides practical matching examples for different payloads:

- Lightweight Payload (up to 1kg): Motor 2204 Brushless (~1400KV), Propeller 5-inch diameter, 4×4 pitch, 2-3 blades.

- Mid-Range Payload (1-1.5kg): Motor 2206 Brushless (~1800KV), Propeller 5.5-inch diameter, 5×4.5 pitch, 3 blades.

- Moderate Payload (2kg): Motor 2306 Brushless (~1500KV), Propeller 6-inch diameter, 6×5 pitch, 3-4 blades.

- Heavy Payload (2.5kg): Motor 2806 Brushless (~1300KV), Propeller 6.5-inch diameter, 7×5 pitch, 3-4 blades.

- Extended Range & Light Payload (up to 1kg): Motor 2204 Brushless (~1100KV), Propeller 6-inch diameter, 5×4 pitch, 2 blades.

A table can also help match frame size, propeller, and motor:

| Frame Size | Propeller Size | Motor Size Range | KV Range |

|---|---|---|---|

| ≤150mm | ≤3″ | 1105-1306 or smaller | 3000KV and higher |

| 180mm | 4″ | 1806, 2204 | 2600KV – 3000KV |

| 210mm | 5″ | 2205-2208, 2305-2306 | 2300KV-2600KV |

| 250mm | 6″ | 2206-2208, 2306 | 2000KV-2300KV |

| 350mm | 7″ | 2506-2508 | 1200KV-1600KV |

| 450mm | 8″ or larger | 26XX and larger | 1200KV and lower |

High KV motors spin faster and suit smaller, lighter propellers, which benefits racing drones. Low KV motors provide more torque for larger propellers, making them ideal for cinematic or heavy-lift drones. Simulation tools and thrust tests help optimize these combinations for specific needs.

Common Mistakes

Many drone builders make sizing errors that affect performance and safety. One frequent mistake involves selecting a propeller that exceeds the frame’s wheelbase. If the propeller blades are too long, they may strike each other during flight, causing mechanical failure or loss of control.

Another common issue arises from mismatched motor and propeller combinations. Using a high KV motor with a large, heavy propeller can overheat the motor and drain the battery quickly. Conversely, pairing a low KV motor with a small propeller may not generate enough thrust for stable flight.

Technical reports show that motor and propeller faults, such as damage or aging, lead to instability. Propeller failures, including breakage or debris, cause thrust fluctuations and imbalance. Drones with two-blade propellers achieve higher fault detection accuracy than those with three-blade propellers, which means propeller configuration also affects reliability.

Tip: Always check that the propeller size fits within the frame’s limits and matches the Drone Motor’s recommended range. Regular inspection of both motors and propellers helps prevent unexpected failures.

Selecting the correct Drone Motor diameter shapes drone performance, efficiency, and reliability. Builders should always match motor size to the frame and propeller. They can follow these steps for best results:

- Check the frame’s recommended motor range.

- Pair the motor with a compatible propeller.

- Consider the drone’s intended use and payload.

A balanced approach leads to safer flights and longer-lasting equipment.