Introduction to RC Electric Motors

RC electric motor sizes are key to how well your RC vehicles perform and how efficiently they run. This guide is for RC hobbyists and enthusiasts looking to understand and select the best electric motor size for their vehicles. Picking the right motor size means your RC car or aircraft will deliver the power and speed you want without wasting energy or risking damage. The RC hobby has come a long way thanks to advances in motor technology and design. Choosing the correct motor size ensures optimal performance, efficiency, and reliability for your RC car or aircraft.

There are two main types of electric motors in RC vehicles: brushed and brushless motors. Each has its own strengths. Brushless motors have become especially popular because they offer better efficiency and require less upkeep than brushed motors.

Knowing important specs like motor KV, voltage, and current helps you choose the right motor for your RC car. It’s also crucial to understand how the motor works with components like electronic speed controllers (ESCs) and batteries to get the most out of your power system.

Choosing the right motor size and type can make a big difference in your RC experience, improving performance, efficiency, and reliability.

Types of RC Electric Motors

Brushed Motors

- Brushed motors are straightforward, affordable, and easy to maintain, but don’t deliver as much power or efficiency. They use brushes and an armature with wire windings to operate. Brushed motors run smoothly at low speeds, which is why they’re still common in RC crawlers. They’re a good choice for beginners, though the brushes wear out over time and need replacing.

Brushless Motors

- Brushless motors offer higher power, better efficiency, and a longer lifespan. Without brushes, they reduce friction and heat buildup. These motors need a specialized ESC to run properly. Brushless motors come with different KV ratings, so you can pick one that fits your needs.

- Lower-kV brushless motors provide more torque, which is great for vehicles like short-course trucks. Higher KV motors are tuned for speed. For more detailed information, check out this comparison: What is better, a brushed or a brushless drone motor? – Retek Motors.

Understanding Brushless Motor Design

Brushless motors have changed the RC world with their efficient, reliable, and powerful design. Unlike brushed motors that rely on physical brushes to transfer electricity, brushless motors use a stationary stator with windings and a rotor with permanent magnets. This cuts down friction and wear, resulting in smoother operation, less maintenance, and higher efficiency.

ESCs manage power delivery to the stator precisely, optimizing performance and control. Knowing how brushless motors work helps you pick the right motor size and type for your RC vehicle, improving speed, efficiency, and overall enjoyment.

Brushless Motors for High Performance

- Brushless motors convert electrical energy into mechanical power with minimal loss, which means less heat and better performance. That’s why they’re the go-to choice for high-performance RC vehicles.

- Their design includes a stator and rotor, removing brushes and cutting down friction. The rotor spins inside the magnetic field created by the stator windings, allowing for high rpm and speed—perfect for racing and flying.

- When picking a brushless motor, pay attention to kv rating, voltage, and current to get the best performance and efficiency. Brushless motors also last longer since they don’t have brushes that wear out.

RC Car Motor Selection

Choosing the right motor size for your RC car depends on power, torque, and battery capacity. Consider your vehicle’s type, weight, and the top speed you want.

Factors to Consider

The power and torque needed vary with the vehicle’s weight, terrain, and speed goals. Larger motors generally provide more power and torque but add weight, which can affect handling and efficiency. A motor that can deliver the needed power without pushing its limits will run more reliably and perform better.

Power System Considerations

ESC and Battery Matching

- Voltage: Look at voltage, current (amps), and power (watts) ratings.

- ESC Rating: The ESC’s current rating should be at least 20% higher than the motor’s maximum current draw.

- Battery Capacity: Battery capacity and type affect overall efficiency and runtime.

- Compatibility: Using the same battery with different motors can lead to different performance and heat levels, so matching motor and battery specs is important.

- Temperature Monitoring: Keep an eye on motor temperature during use to avoid overheating and damage.

Flite Test and Motor Performance

A flight test is a practical way to check motor performance. Using a motor stand, you can measure rpm, current, and voltage with different propeller sizes to see how efficient your motor is.

Flite testing helps you figure out if a motor suits your RC vehicle and guides you on adjustments to improve performance. Choosing the right propeller size is crucial for matching the motor’s capabilities to what your vehicle needs.

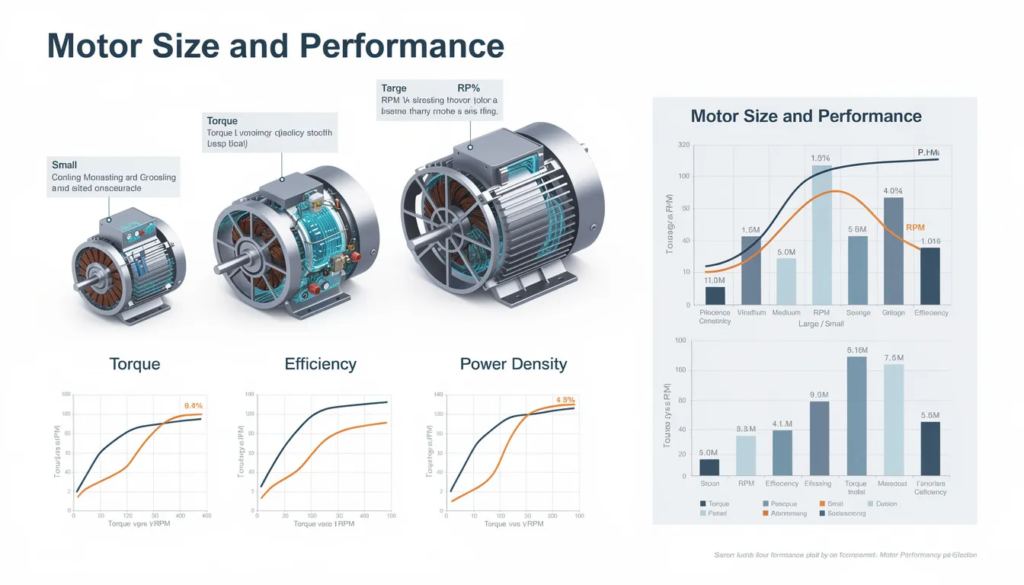

Motor Size and Performance

RC electric motors are designated by their physical dimensions, typically measured in diameter and length in millimeters. Many motors are referred to by a number that indicates their dimensions, such as 540, 4068, or 4076. Motor sizes are commonly identified by a four-digit number representing diameter and length, such as 3650 for a 36mm diameter and 50mm length motor.

Motor size affects power and torque directly. RC electric motor sizes are usually shown by diameter and length in millimeters, often as a four-digit number (for example, 3650 means 36mm diameter and 50mm length).

Here are some common examples of motor sizes and their typical applications:

- 370 / 380: Used in micro and mini vehicles.

- 540: Common in most 1/10 scale cars.

- 4068, 4076: Used in larger or more powerful RC vehicles.

Motor sizing can be confusing since manufacturers don’t always follow the same standards.

Larger motors generally produce more torque, which heavier vehicles and off-road models need, but they also add weight and cost. The diameter and length influence torque and speed characteristics—longer motors tend to offer more torque, while shorter motors favor speed.

Motors with the same KV rating can differ in size and performance depending on the brand. Brands like Cobra and Turnigy SK3 offer motors that handle higher power outputs for various RC vehicles.

To help you quickly compare, here’s a summary table of common RC electric motor sizes and their typical applications:

| Motor Size | Typical Application | Notes on Sizing Conventions |

|---|---|---|

| 370/380 | Micro and mini vehicles | Sizing conventions can vary by manufacturer |

| 540 | Most 1/10 scale cars | Standard for many RC cars |

| 3650 | 1/10 scale cars, boats | 36mm diameter, 50mm length |

| 4068 | Large 1/8 scale vehicles | 40mm diameter, 68mm length |

| 4076 | Large, high-power vehicles | 40mm diameter, 76mm length |

Turn/KV and Motor Performance

The motor KV rating impacts performance: higher KV motors spin faster, while lower KV motors provide more torque. KV is a velocity constant that indicates how many RPM a motor turns per volt with no load. KV is measured in rpm per volt with no load.

For every kilovolt, a motor turns one rpm per volt applied. Higher kv motors use battery power faster and produce less torque, which can cause overheating if not managed well.

Choosing the right kv rating depends on your vehicle’s use and performance goals. The right kv balances speed and torque for efficient operation.

Poles and Motor Performance

The number of poles in a brushless motor refers to the number of magnets on the rotor, affecting torque and RPM control. More poles mean more torque, which is helpful for vehicles like short-course trucks and buggies that need strong pulling power.

However, more poles can impact smoothness at high rpm, important for racing and aircraft models. Typically, 2-pole motors suit speed-focused vehicles, while 4-pole or 6-pole motors offer better torque and control for heavier loads and rough terrain.

Picking the right pole count ensures your RC vehicle performs well for its intended use.

Sensored vs. Sensorless Motors

Sensored motors have sensors that give feedback to the ESC for precise control and better efficiency. Sensorless motors rely on the ESC to estimate rotor position and speed.

Sensored motors usually cost more and are more complex, but deliver superior performance. Your choice depends on the vehicle type, how you plan to use it, and the performance you want.

Timing and Motor Performance

Adjusting motor timing changes power output and efficiency. Increasing timing can boost power and top speed, but also raises heat and lowers efficiency.

Finding the right timing balance is key to avoiding overheating and keeping your motor reliable. Monitoring motor temperature and adjusting timing as needed helps you get the best speed, torque, and efficiency.

Conclusion: Choosing the Right RC Electric Motor Sizes for Optimal Performance

Choosing the right RC electric motor sizes is essential for getting the best performance and efficiency from your RC vehicle. By considering factors like power, torque, battery capacity, and motor KV rating, you can find a motor that fits your needs.

In my experience, matching motor size and specs to your vehicle’s weight, use, and goals makes all the difference (pros and cons of servo motors). Using quality components from trusted manufacturers like Retek Motion helps ensure reliability and smooth operation.

For more guidance on motor selection and RC power systems, check out resources at RC Superstore, Innov8tive Designs, and Common Sense RC for expert advice and detailed guides.