Quadcopter motors are fundamental components that determine the performance, efficiency, and reliability of your drone. When it comes to building or upgrading a drone, selecting the right quadcopter motors is essential for achieving optimal results. Whether you’re flying an FPV drone for racing or operating industrial drones for delivery and logistics, understanding the different motor types, their specifications, and how they interact with other components like electronic speed controllers (ESCs) can significantly impact your drone’s flight capabilities. This guide by Retek Motion will walk you through everything you need to know about quadcopter motors, helping you make an informed decision that matches your drone’s demands.

Understanding Quadcopter Motors and Their Importance

Quadcopter motors are the heart of any drone, providing the necessary thrust and torque to lift the drone and maneuver it smoothly through the air. Drone motors convert electrical power into mechanical power, spinning the propellers to generate lift. The choice of motors directly influences the drone’s payload capacity, flight time, and overall performance.

Motors provide the torque and thrust needed to lift the drone, especially when carrying heavier payloads or flying longer distances. Efficient motors ensure longer flight times by optimizing power consumption, while high-performance motors are essential for delivering power, thrust, efficiency, and smooth handling for optimal drone performance in racing, freestyle, or cinematic flying. Therefore, selecting the right motor is crucial to match the specific application and flight requirements of your drone.

For more detailed information on drone motor technology, you can visit Grepow’s comprehensive guide. Additionally, to explore high-quality motor options for FPV drones, RaceDayQuads offers a great selection. For industrial applications, Unmanned Systems Technology provides valuable insights into heavy-lift drone motors.

Types of Quadcopter Motors: Brushless vs. Brushed

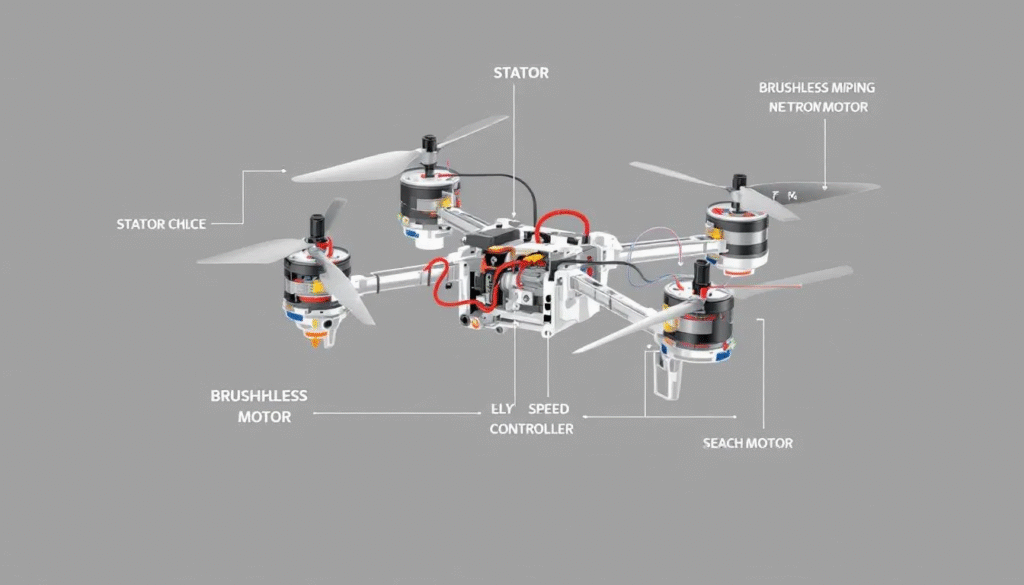

When selecting quadcopter motors, understanding the difference between brushless motors and brushed motors is vital. Brushless motors are widely preferred in modern drones due to their superior efficiency, durability, and power. These motors are designed without brushes, which reduces friction and heat, resulting in smoother operation and longer lifespan. Brushless motors have a stator with copper windings and a rotor with permanent magnets, which enhances their performance and reliability. Brushless motors also offer higher torque and thrust, making them suitable for drones that require high performance and reliability, such as industrial drones and FPV drones.

On the other hand, brushed motors are simpler and less expensive but tend to wear out faster because of the brushes that cause friction and overheating. The brushes make contact with the rotor to conduct electricity, which contributes to wear and reduces the motor’s lifespan. A variation of brushed motors, known as coreless motors, features a rotor without an iron core, making them extremely lightweight and low-inertia. Brushed motors are typically found in smaller, lighter drones or beginner models where cost is a significant factor. However, for applications demanding precision, high torque, and longer flight times, brushless motors are the better choice.

Key Specifications to Consider in Quadcopter Motors

When choosing quadcopter motors, several specifications determine their suitability for your drone’s needs:

- Size and Weight: Smaller motors are lighter and ideal for lightweight drones or racing configurations, while larger motors can handle heavier payloads and provide more thrust. Smaller motors are also more responsive but have lower thrust and power output.

- Torque and Thrust: High torque motors are essential for lifting heavier payloads and ensuring stable flight, especially in delivery drones or industrial applications.

- Power and Efficiency: Efficient motors consume less power, contributing to longer flight times and better battery life.

- Durability and Reliability: Motors should be built to withstand the operational stresses, including heat and mechanical wear, ensuring consistent performance during flight.

- Compatibility with ESCs: The electronic speed controller (ESC) must be compatible with the motor to ensure smooth control and responsiveness, preventing issues like overheating and motor failure.

- Weight Impact: The weight of the motor affects the overall weight of the drone, which in turn influences flight time and maneuverability.

Additionally, the number of poles and magnets in a motor can influence its performance and how quickly it can respond to control inputs, depending on the motor’s design and intended application. Higher pole and magnet counts generally increase the torque output of the motor. This relationship affects the agility and stability of your drone during flight.

ESC and Motor Compatibility: Ensuring Seamless Integration

When building or upgrading a drone, ensuring that your drone motors and Electronic Speed Controllers (ESCs) are perfectly matched is crucial for achieving smooth operation and high performance. The ESC acts as the bridge between your flight controller and the motors, regulating the power and speed delivered to each motor. This is especially important for brushless motors and high torque motors, which are commonly used in industrial drones and applications that demand maximum reliability and efficiency.

Selecting the right motor and ESC combination starts with understanding the power requirements of your drone. High torque motors, for example, require ESCs that can handle higher current loads without overheating or causing power loss. Using an ESC with insufficient capacity can lead to reduced performance, erratic motor behavior, or even permanent damage to your drone’s components. For industrial drones that carry heavier payloads or operate over long distances, the reliability of this pairing becomes even more critical.

Key factors to consider include the ESC’s current rating, voltage compatibility, and supported firmware. The ESC must be able to deliver consistent power to the motor, especially during demanding maneuvers or when lifting heavier payloads. Additionally, advanced ESCs offer features like smooth throttle response and precise control, which are essential for high performance and efficient operation. To ensure safety and prevent burnout, the ESC’s continuous current rating should be 20-30% higher than the motor’s maximum continuous current draw.

To ensure seamless integration, always review the manufacturer’s recommendations for both motors and ESCs, and consider testing your chosen combination under real-world conditions. This approach helps you achieve the best balance of power, efficiency, and reliability, ensuring your drone motors perform at their peak and your drone operates safely and effectively in any application.

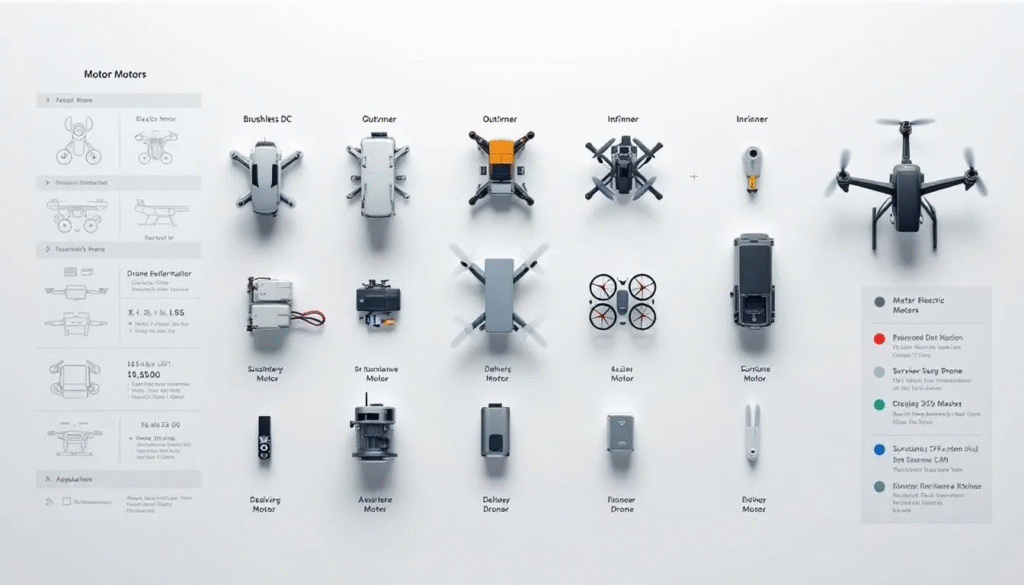

Matching Motors to Drone Applications

Different drone applications require different motor configurations and performance characteristics. For instance, FPV drones used in racing demand high-performance brushless motors that provide quick responsiveness and high thrust-to-weight ratios. These motors allow pilots to execute agile maneuvers and maintain precision control during freestyle flying. Lightweight motors with higher KV ratings offer faster response times and improved agility for FPV racing drones. For racing, thrust-to-weight ratios can be significantly higher, often 8:1 or 10:1, to achieve maximum agility and acceleration.

In contrast, delivery drones and industrial drones prioritize payload capacity and longer flight times. For these drones, high-torque motors combined with efficient ESCs are essential to handle heavier payloads and operate over long distances reliably. High-torque motors are specifically designed to maintain rotational force even at lower RPMs, making them suitable for lifting heavy loads. These motors provide the necessary power and durability to meet the demands of logistics and delivery operations.

Selecting the Right Motor: Tips and Tools

Choosing the right motor involves considering the drone’s size, weight, intended use, and performance goals. Here are some tips to help you find the perfect quadcopter motor:

- Assess Your Drone’s Requirements: Determine the payload capacity, desired flight time, and performance level needed.

- Choose the Motor Size and Type: Select brushless motors for high performance and durability, especially for heavier drones or demanding applications.

- Match Motors with ESCs: Ensure your ESCs are compatible with the motors to provide smooth operation and prevent overheating.

- Consider High Torque Motors: For applications requiring heavy lifting, prioritize motors designed to deliver high torque.

- Review Manufacturer Specifications: Brands like Retek Motion and T Motor offer a range of powerful and efficient motors designed for various drone configurations.

- Check Stock Availability: Before purchasing, check the stock availability of motors and related components, as popular models may have limited stock and sell out quickly.

- Test and Evaluate: Whenever possible, test motors in real-world conditions to evaluate their performance, responsiveness, and reliability.

Conclusion: Ensuring Optimal Drone Performance with the Right Quadcopter Motors

Selecting the right quadcopter motors is essential for building a drone that meets your specific flight and operational demands. Whether you are flying lightweight FPV drones for racing or operating industrial drones designed for delivery, understanding motor types, specifications, and compatibility with ESCs will help you optimize your drone’s power, efficiency, and reliability. By carefully reviewing options and matching motors to your drone’s design and application, you can ensure smooth operation, longer flight times, and the ability to handle heavier payloads with confidence. Make sure to continue exploring and testing different motors to find the perfect fit for your drone build and enjoy enhanced flight performance with Retek Motion’s trusted motor solutions.