Selecting the best drone motor is a critical decision that significantly influences your drone’s overall performance, efficiency, and lifespan. Whether you’re building an FPV drone, a racing drone, or a long-range aerial platform, understanding the intricacies of drone motors—from motor construction to motor KV and torque—is essential for optimizing flight characteristics.

The choice of motor directly impacts the drone’s performance, including efficiency, stability, and overall flight capabilities. Additionally, battery voltage compatibility, typically measured in cells (e.g., 3S, 4S, 6S), is a crucial factor to consider when selecting motors to ensure optimal performance and prevent damage. This article, brought to you by Retek Motion, delves into the key factors that determine the best drone motor for your specific needs and provides expert insights into motor performance, design, and compatibility.

Understanding Drone Motors: Brushless vs. Brushed Motors

When it comes to drone motors, the two primary types you will encounter are brushed motors and brushless motors. Brushed motors are simpler in design but generally less efficient and durable than brushless motors. A brushed motor uses mechanical brushes for commutation, which makes it less advanced in technology, lower in performance, and less reliable compared to brushless DC motors and AC motors, especially for demanding applications like heavy lift drones and other high-performance uses. Brushed motors are typically used in cost-effective toy drones due to their simpler design.

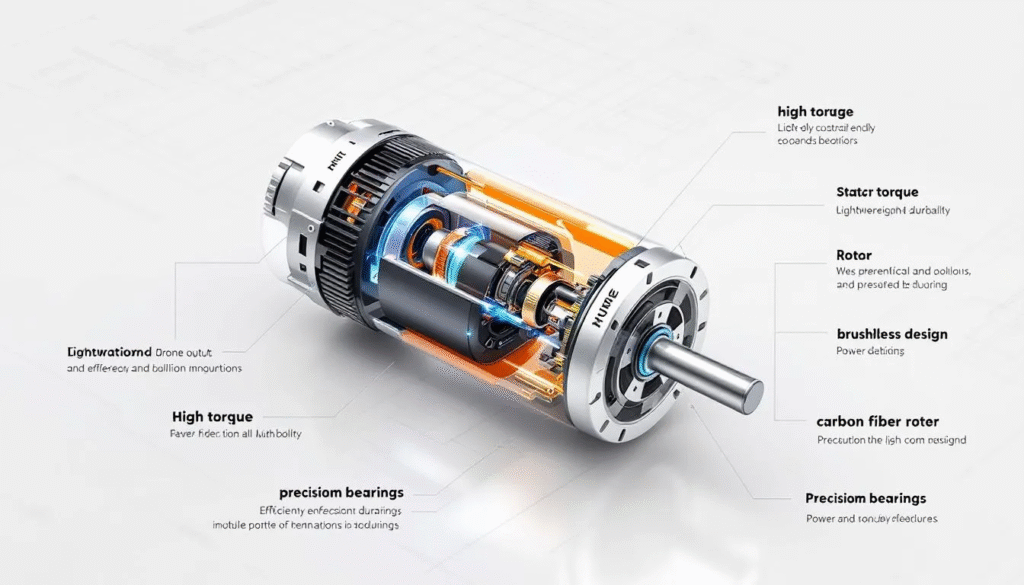

Brushless motors are generally more powerful and durable than brushed motors and have become the industry standard for drones due to their superior motor performance, longer lifespan, and ability to deliver higher torque and motor rpm. The absence of brushes reduces friction and heat generation, allowing brushless motors to maintain optimal performance during extended flights.

Brushless motors rely on a combination of permanent magnets and stator coils to generate rotation around the motor’s rotational axis. This motor construction ensures reliable performance and smoother operation, making brushless motors ideal for FPV drones, racing drones, and other high-performance applications. In contrast, brushed motors are typically found in micro drones or beginner models where cost and simplicity are prioritized over raw performance.

Drone Motor Applications

Drone motors are at the heart of a wide range of applications, each demanding a unique set of motor characteristics to achieve optimal performance. For racing drones, high-torque motors are essential for delivering the rapid acceleration and agility needed to navigate tight courses and sharp turns. These motors are engineered for quick response and high power output, making them the preferred choice for competitive pilots seeking an edge in speed and maneuverability.

In contrast, long-range drones prioritize efficiency and endurance, requiring motors that can deliver sustained power while minimizing energy consumption. Here, the focus shifts to motors designed for smooth, reliable performance over extended flight times, ensuring that the drone can cover greater distances without sacrificing stability or safety.

Commercial applications, such as aerial photography, surveying, and package delivery, often demand a robust combination of thrust, efficiency, and reliability. Selecting the right motors for these tasks ensures that payloads are lifted safely and that the drone can operate consistently in various conditions. By understanding the specific requirements of your application—whether it’s high-speed racing, long-range exploration, or professional-grade aerial work—you can choose motors that deliver the performance and reliability your drone needs.

Key Features of the Best Drone Motor

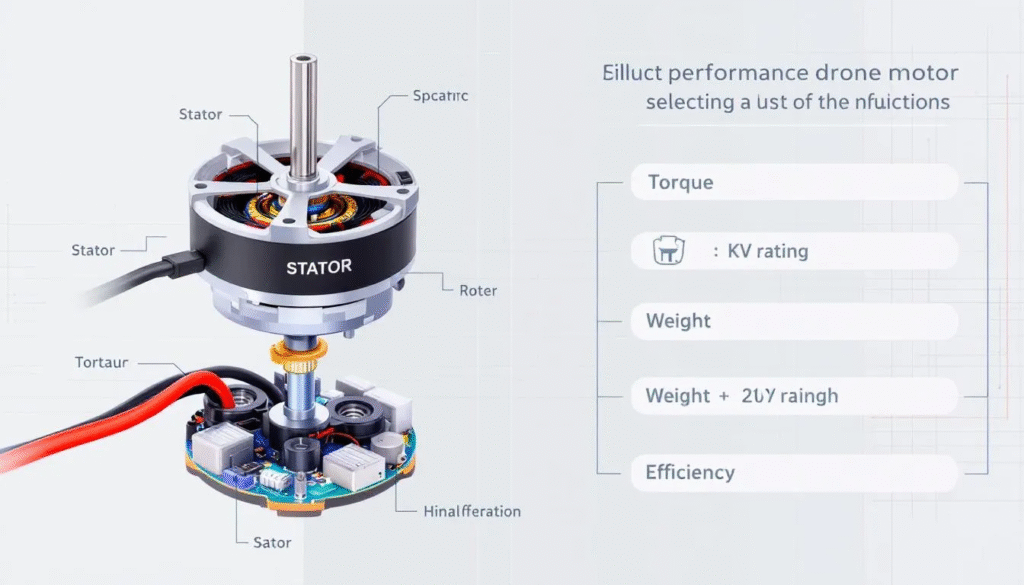

Choosing the best drone motor involves evaluating several critical factors that influence how the motor will perform in your specific drone setup. These key features include motor KV, motor torque, motor size, stator volume, and motor windings.

- Motor KV and Motor RPM: Motor KV represents the number of revolutions per minute (rpm) the motor will spin per volt applied without load. Higher kv motors spin faster, making them suitable for smaller propellers and racing drones where speed is paramount. Conversely, lower-kV motors generate more torque, which is essential for lifting heavier propellers and achieving a greater thrust-to-weight ratio. Higher kv motors spin propellers faster, generating more thrust-to-weight, consuming more current, which can impact efficiency and battery life. KV rating indicates the RPM a motor turns at 1V without a load, affecting power and thrust generation.

- Motor Torque and Torque Constant: Motor torque is the rotational force the motor produces, directly affecting the drone’s ability to lift and maneuver. High torque motors are advantageous for drones with heavier propellers or those requiring increased thrust. The torque constant is a measure of how efficiently the motor converts electrical power into torque, influencing overall motor efficiency. The motor’s ability to handle higher currents and generate greater torque is influenced by factors such as windings, wire thickness, and specific design features.

- Motor Size and Stator Volume: The motor size, particularly the stator volume (the combined width and height of the motor stator), is a critical determinant of motor performance. Stator size directly influences torque, power capacity, and responsiveness, making it a key factor when selecting motors for different drone applications. Larger motors with greater stator volume can house more stator coils and copper windings, allowing them to generate more torque and handle higher currents.

The best drone motors often balance stator width and stator height to optimize heat dissipation and maintain a robust combination of torque and rpm. Motors with the same stator volume but different physical dimensions (wider vs. taller) can behave differently in terms of cooling, responsiveness, and torque. When comparing different motor sizes, the number of poles and magnets also affects performance, smoothness, and control, with higher pole counts generally providing smoother operation and more precise control.

Even with the same kv rating, motors with different stator sizes or weights can have varying cooling and response characteristics. Using the same propellers with different motor types or dimensions can lead to variations in responsiveness, cooling, and efficiency. Motors with different stator geometries can maintain the same thrust output but differ in responsiveness, cooling, and torque. A heavier motor, due to larger stators and heavier windings, can provide greater torque but may impact weight efficiency and agility.

- Motor Bell and Bearings: The motor bell houses the permanent magnets and rotates around the stator. Motor bells made with high-quality materials and equipped with ceramic bearings contribute to smoother rotation, reduced friction, and longer motor lifespan. Larger bearings in wider and shorter motors can enhance durability and support heavier propellers.

- Motor Windings and Poles: The number of stator coils and poles affects the motor’s torque and rpm characteristics. Motors with fewer poles generally achieve higher rpm but lower torque, while those with more poles provide greater torque at lower rpm. Selecting the right winding configuration depends on your drone’s flying style and frame size.

Matching Motor Characteristics to Drone Requirements

To achieve optimal performance, the motor’s specifications must align with the drone’s total weight, frame size, and intended flying style.

- Estimated Total Weight and Thrust to Weight Ratio: The drone’s total weight, including the frame, battery, electronics, and payload, is a critical factor in motor selection. The motor’s ability to generate maximum thrust must exceed the drone’s weight to maintain a healthy thrust to weight ratio. Generally, a thrust to weight ratio of 2:1 or higher is thrust-to-weightile flight, and maneuvthrust-to-weightd starting thrust-to-weight ratio for drones is 2:1, with racing drones aiming for 4:1 or higher for aggressive maneuvers. A thrust-to-weight ratio of 2:1 is considered necessary for basic lift, while a 5:1 ratio is ideal for racing.

- Propeller Size and Motor Compatibility: Maximum propeller size is constrained by motor size and kv. Lower-kV motors paired with larger propellers deliver increased torque and thrust. Lower-kV for long-range or heavy-lift applications. When using low kv motors with larger props and higher voltage batteries, it is important to slow-kV low-kV motors to optimize thrust and power while minimizing the risk of overheating and motor damage. Air resistance causes the actual RPM to decrease when a propeller is mounted, which can lead to increased motor heating and impacts overall performance. Higher KV motors are better suited for lighter propeller racing drones that prioritize speed over raw thrust.

- Flying Style and Motor Recommendations: Racing drones require high kv motors with rapid motor rpm to achieve quick acceleration and high top speed. Long-range FPV drones benefit from lower kv motors that provide greater torque and efficiency, extending flight time and improving stability. Choosing the right FPV drone motor is essential for optimal performance, durability, and efficiency, as construction and design features influence responsiveness, weight, and power consumption. Key features and design considerations of FPV drone motors for racing and freestyle flying include windings, pole count, and securing methods, all of which affect motor responsiveness and reliability.

Motor Construction and Design Considerations

The internal design and materials used in drone motors significantly impact their performance and reliability.

- Stator Coils and Copper Windings: The quality and configuration of stator coils and copper windings affect the motor’s efficiency and heat dissipation. More copper windings can increase motor torque but may also increase resistance and heat generation. Managing heat and ensuring proper cooling are essential for extending the motor’s lifespan, as excessive heat can lead to magnet demagnetization and reduced durability. Optimal motor construction balances these factors to deliver consistent performance.

- Permanent Magnets and Magnetic Flux: High-quality permanent magnets enhance magnetic flux, which increases torque generated and motor efficiency. Motor manufacturers often use neodymium magnets in brushless motors for their strong magnetic properties.

- Motor Size: Taller vs. Wider Motors: Taller motors often have longer stator height and can accommodate more windings, resulting in higher torque. Wider and shorter motors, on the other hand, may feature larger bearings and better heat dissipation, which improves motor lifespan and reliability.

Electronic Speed Controller (ESC) Compatibility

The electronic speed controller (ESC) plays a vital role in managing motor rpm and rotation direction. Selecting an ESC compatible with your motor’s maximum current and kv rating ensures smooth throttle response and prevents overheating. Advanced ESCs also support features like bidirectional rotation, which is essential for certain flight controllers and drone configurations. For more details on ESCs, you can visit Oscar Liang’s ESC Guide.

Motor Cost and Value

When selecting drone motors, cost is an important consideration, but it should always be weighed against the value the motor provides. Basic brushed motors are available at a low price point, making them suitable for entry-level or micro drones where budget is a primary concern. However, for most drone enthusiasts and professionals, investing in a high-quality brushless motor is a smarter choice. Brushless motors offer superior performance, greater efficiency, and a much longer lifespan compared to brushed motors, justifying their higher initial cost.

The true value of a motor lies in its ability to deliver reliable performance over time. High performance brushless motors often feature advanced designs, premium materialHigh-performancedurability, which can reduce maintenance needs and minimize the risk of unexpected failures. When evaluating the cost of drone motors, consider not only the purchase price but also the total cost of ownership, including potential repair or replacement expenses. In many cases, a more expensive brushless motor will prove to be a better investment, offering consistent performance and a longer service life that ultimately saves money in the long run.

Motor Safety and Reliability

Ensuring the safety and reliability of your drone motors is crucial for both performance and peace of mind. A well-designed motor, featuring a robust motor bell and high-quality internal components, is less likely to suffer from mechanical failures that could compromise your drone’s operation. Reliable performance starts with proper installation—making sure that motors are securely mounted, connections are tight, and all components are free from damage or defects.

Regular inspection and maintenance of key parts, such as the motor bell, stator, and windings, helps prevent issues before they arise. Following manufacturer guidelines for usage and care is essential, as is choosing motors from reputable brands known for their quality and reliability. Pairing your motors with a high-quality electronic speed controller (ESC) further enhances safety, reducing the risk of electrical faults or overheating. By prioritizing safety and reliability in your motor selection and maintenance routines, you can enjoy worry-free flights and protect your investment in drone technology.

Drone Motor Maintenance and Repair

To keep your drone motors operating at peak efficiency, regular maintenance is essential. Simple tasks like cleaning dust and debris from the motor, checking for signs of wear on the bearings or motor bell, and ensuring that all connections remain secure can go a long way toward preserving optimal performance. Inspecting the stator and windings for damage or overheating is especially important for high-performance motors, which are often pushed to their limits during demanding flights.

When a motor does become damaged, the decision to repair or replace it depends on the severity of the issue and the value of the motor. For many drone motors, especially those used in high-performance applications, replacement is often more cost-effective than attempting complex repairs. However, for enthusiasts with the right skills and tools, tasks like rewinding stators or replacing bearings can extend the life of a favorite motor. By staying proactive with maintenance and addressing issues promptly, you can maximize the lifespan of your motors and ensure your drone continues to deliver reliable, high-quality performance.

Motor Manufacturers and Market Options

Several reputable motor manufacturers specialize in producing high-quality drone motors tailored to various applications. Brands like T Motor are renowned for their robust combination of motor size, performance, and reliability. Retek Motion proudly offers a selection of premium drone motors designed to meet the diverse needs of drone enthusiasts and professionals alike. Reputable brands in the FPV space include T-Motor, EMAX, iFlight, and RCinpower. The EMAX ECO II motors are considered some of the best budget FPV motors over the years. When selecting a motor, consider the manufacturer’s reputation, customer reviews, and availability of spare parts to ensure long-term support. For more insights on the best motors for drones, check Oscar Liang’s Motor Recommendations.

Future of Drone Motors

The future of drone motors is marked by rapid innovation and exciting advancements in motor performance, efficiency, and reliability. Researchers and engineers are continually exploring new materials, such as carbon fiber composites and nanomaterials, to create lighter and stronger motors that can withstand the rigors of modern drone applications. These advancements not only reduce the overall weight of drone motors but also enhance their durability and power output. Stronger magnets in brushless motors enhance torque and responsiveness in performance, further pushing the boundaries of what drone motors can achieve.

Innovations in motor design, including more efficient stator and rotor configurations, are pushing the boundaries of what drone motors can achieve. The integration of artificial intelligence and machine learning into motor control systems promises to revolutionize how motors respond to changing flight conditions, enabling real-time optimization for maximum efficiency and performance. As drone technology evolves, we can expect to see motors that are not only more powerful and efficient but also smarter and more adaptable, opening the door to new applications in areas like high-speed racing, long-endurance surveillance, and beyond. The ongoing evolution of drone motors will continue to drive the capabilities of drones to new heights, making them an even more integral part of our technological landscape.

Conclusion: Choosing the Right Motor for Optimal Drone Performance

Selecting the best drone motor is a balance of understanding motor KV, torque, size, and construction in relation to your drone’s total weight, frame size, and flying style. Brushless motors dominate the market for their superior motor performance, longer lifespan, and ability to handle higher currents and torque. Whether you need high torque motors for heavier propellers or higher kv motors for speed-focused racing drones, prioritizing key features like stator volume, motor windings, and motor bell quality will lead to optimal performance.

By carefully matching motor characteristics to your drone’s requirements and ensuring compatibility with your electronic speed controller, you can achieve a robust and reliable setup. This not only enhances flight efficiency and thrust to weight ratio but also extends the motor’s lifespan, ensuring your drone’s thrust-to-weight in every flight. For more tips on drone building and motor selection, visit Retek Motion’s Drone Resource Center.