Introduction to Large Brushless Electric Motors

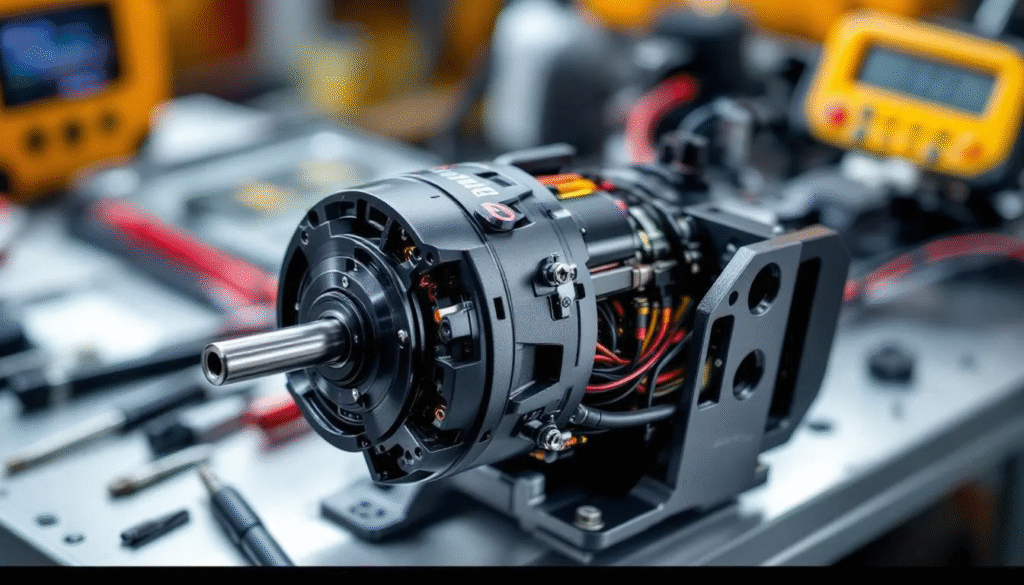

Large brushless electric motor technology has revolutionized various industries by offering superior performance and reliability. Unlike traditional brushed DC motors, brushless motors eliminate the need for brushes, which reduces friction and wear, resulting in longer service life and enhanced efficiency. Retek Motion specializes in providing high-quality, large brushless electric motors designed to meet the demands of a diverse range of applications.

Large brushless electric motors, including BLDC motor models, are engineered for high-performance and reliability in demanding environments. These motors are particularly valued for their ability to deliver high power output and torque while maintaining a compact and durable design. Their brushless design makes them suitable for applications demanding high efficiency, reliability, and robustness under diverse operating conditions.

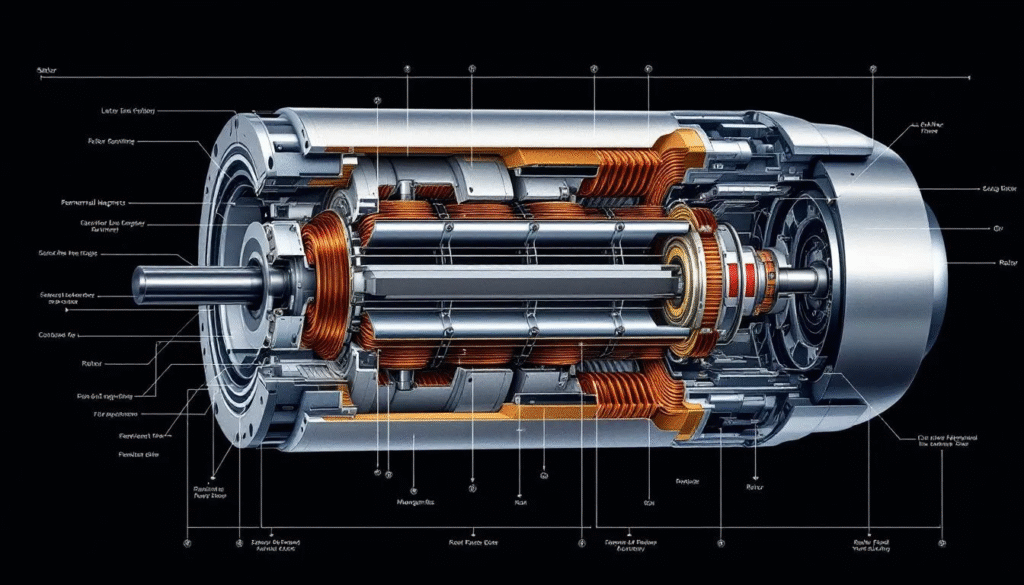

How Brushless DC Motors Work

Brushless DC motors, often referred to as BLDC motors, represent a significant advancement in electric motor technology, especially for applications demanding high efficiency, reliability, and robust performance. Unlike traditional brushed DC motors, which rely on physical brushes to transfer current to the rotor, brushless DC motors utilize a brushless design that eliminates mechanical contact, reducing friction and wear. This fundamental difference not only extends the service life of the motor but also enhances its overall efficiency and reliability.

At the heart of a brushless DC motor are two main components: the stator and the rotor. The stator, which remains stationary, is composed of multiple windings arranged to create a rotating magnetic field when energized. The rotor, typically embedded with high-strength permanent magnets, responds to this magnetic field, generating the torque necessary to drive the motor shaft. This interaction between the stator’s electromagnetic field and the rotor’s permanent magnets is what enables BLDC motors to deliver high power output and precise speed control.

One of the standout features of BLDC motors is their ability to operate at very high speeds while maintaining high efficiency. Thanks to innovative winding technology and the use of advanced materials, these motors can achieve maximum thrust and sufficient power for demanding applications such as heavy lift drones, electric aircraft, and unmanned aerial vehicles. The absence of brushes also means that BLDC motors can reliably operate in harsh environments and extreme temperatures, making them suitable for a wide range of operating conditions.

The performance of a brushless DC motor is closely tied to its operating parameters, including voltage, current, and temperature. Proper management of these factors ensures optimal power output, torque, and speed, while also safeguarding the motor’s long service life. Motor efficiency affects the flight time and payload capacity of drones, making it a critical consideration in applications where performance and endurance are paramount. Bearings play a crucial role in supporting the rotor and enabling smooth, high-speed rotation, further contributing to the motor’s durability and reliability.

While the initial price of a brushless DC motor may be higher than that of a brushed DC motor, the investment is often justified by the longer service life, reduced maintenance, and superior performance. For example, high-performance models like the T-MOTOR U15II KV80 can deliver up to 8580W of power and 36.5 kg of thrust, while the SUPER-E S150 boasts a maximum power output of 42kW and a maximum thrust of 160 kg. These capabilities make BLDC motors the preferred choice for applications where high power, efficiency, and reliability are paramount.

In summary, brushless DC motors combine advanced engineering with a robust, brushless design to meet the specific needs of modern electric motor applications. Their ability to deliver high efficiency, operate at very high speeds, and withstand extreme conditions makes them indispensable in fields ranging from heavy lift drones to electric aircraft and beyond.

Advantages of Brushless DC Motors

Brushless DC motors (BLDC motors) offer several advantages over their brushed counterparts. One of the primary benefits is their high efficiency, which translates to reduced energy consumption and better performance. Power ratings, typically measured in watts, are essential for ensuring that the motor meets the thrust and lifting requirements of demanding applications.

The absence of brushes means less mechanical wear, leading to a longer service life and lower maintenance costs. Additionally, brushless motors provide precise speed control and can sustain very high speeds, making them ideal for applications requiring variable speed operation and high torque. Because brushless motors do not have brushes, they have lower noise emissions compared to brushed motors.

Their robust design also enables them to operate reliably in harsh environments and extreme temperatures, further expanding their range of use. For more detailed information, you can visit How Brushless Motors Work and learn about the inner workings and benefits of brushless motor technology.

Design Features of Large Brushless Electric Motors

A large brushless electric motor typically features a four-pole motor configuration, which contributes to its ability to deliver high torque and stable operation. The motor’s stator and rotor are designed with innovative winding technology that enhances power output and efficiency. Bearings used in these motors are selected to maximize bearing life, ensuring longer service life even under heavy loads. The motor length and shaft dimensions are optimized to balance weight and performance, making the motor suitable for applications where both power and compactness are critical.

Cooling systems are often integrated to maintain optimal operating temperatures, supporting continuous power delivery and preventing overheating. The maximum voltage for these motors is limited by mechanical and insulation safety considerations to ensure reliable performance and durability. For technical specifications and purchasing options, Retek Motion offers a wide selection of units equipped with advanced cooling and durable materials.

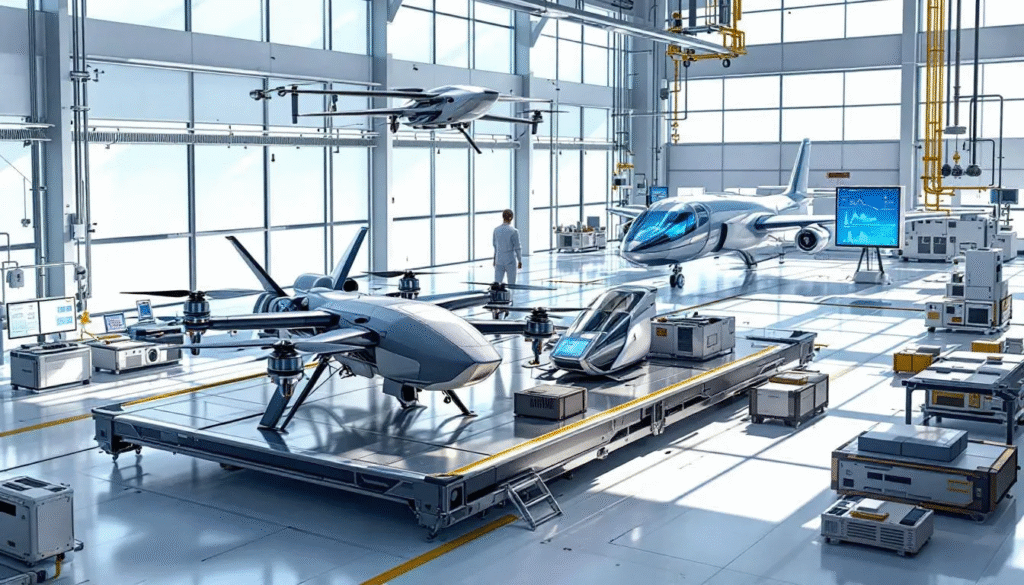

Applications in Heavy Lift Drones and Electric Aircraft

In the rapidly growing market of unmanned aerial vehicles (UAVs), large brushless electric motors are indispensable. Heavy lift drones, which require motors capable of providing maximum thrust and sufficient power, rely heavily on brushless motors to achieve high efficiency and reliability. The most common type of motor used in heavy lift drones is the electric brushless DC motor, preferred for its efficiency. These heavy lift motors must operate within a specific voltage range and deliver both max power and continuous power to sustain flight under various conditions.

The propeller plays a critical role in the propulsion system, and selecting the right propeller size to match the motor specifications is essential for optimal lift capacity and efficiency. Similarly, electric aircraft benefit from the high power and torque capabilities of brushless electric motors, enabling them to operate at very high speeds while maintaining durability and long service life. The robust design of these motors ensures they can withstand the demanding operating conditions encountered in aviation and are suitable for various applications in the aviation and UAV sectors. For an example of such motors in aviation, see magniX electric aircraft motors.

Performance Metrics and Specifications

When selecting a large brushless electric motor, key information such as max voltage, peak power, and continuous power ratings is critical. The voltage range of these motors determines their compatibility with different power systems, while the max power and peak power ratings indicate their capability to handle transient loads and deliver bursts of energy when needed. Thrust requirements should be calculated based on the total weight of the drone and its payload.

Efficiency is a crucial performance metric, as it affects the overall energy consumption and heat generation. Torque and speed specifications must align with the specific needs of the application to ensure sufficient power and optimal performance. Additionally, the motor’s resistance and load current characteristics influence its thermal management and reliability.

Market Availability and Purchase Considerations

The market offers a wide range of large brushless electric motors tailored to diverse applications, including industrial machinery, electric vehicles, and aerospace systems. Prices for these motors vary based on factors such as power output, materials used, motor length, and additional features like cooling systems. When purchasing a brushless motor, it is important to consider the delivery time, warranty, and after-sales support.

Buyers should also evaluate the motor’s compatibility with their system requirements, including voltage, speed, and load capacity. Durable and reliable motors that can operate efficiently in harsh environments and extreme temperatures are highly sought after for long-term use. Retek Motion provides expert consultation to assist in selecting the ideal motor unit for your specific needs.

Conclusion: Large Brushless Electric Motor Advantages and Future Outlook

Large brushless electric motors represent a significant advancement in electric motor technology, offering high efficiency, durability, and robust performance across a wide range of applications. Their brushless design, combined with innovative winding technology and optimized mechanical components, ensures long service life and reliable operation even under demanding conditions. The absence of physical contact components in brushless motors leads to a significantly extended operational life, often tens of thousands of hours.

Whether used in heavy lift drones, electric aircraft, or industrial systems, these motors provide the necessary power, torque, and speed control to meet specific needs. As the market continues to evolve, the demand for high-quality brushless electric motors capable of delivering maximum thrust and continuous power will only increase, making them a vital component in modern electric motor systems.