Yes, many drones use servo motors. You will find that these motors help drones achieve precise control over movement and positioning. When you want a drone to adjust its camera angle or move a control surface, servo motors make this possible. Some drone designs rely on these motors for specific tasks that require accuracy.

Key Takeaways

- Servo motors give drones precise control for moving parts like cameras and flight surfaces, making them essential for tasks needing accuracy.

- Digital servo motors are common in drones because they offer fast response and high precision, improving stability and smooth camera shots.

- Servo motors provide benefits like quiet operation, consistent torque, and reliable positioning but add weight and use more battery power.

- Brushless motors power drone flight with high efficiency, while servo motors handle exact movements; choosing the right motor depends on the drone’s needs.

- Not all drones use servo motors; multirotors often rely on motor speed changes for control, but drones with moving parts like gimbals usually need servos.

What Are Servo Motors?

Definition

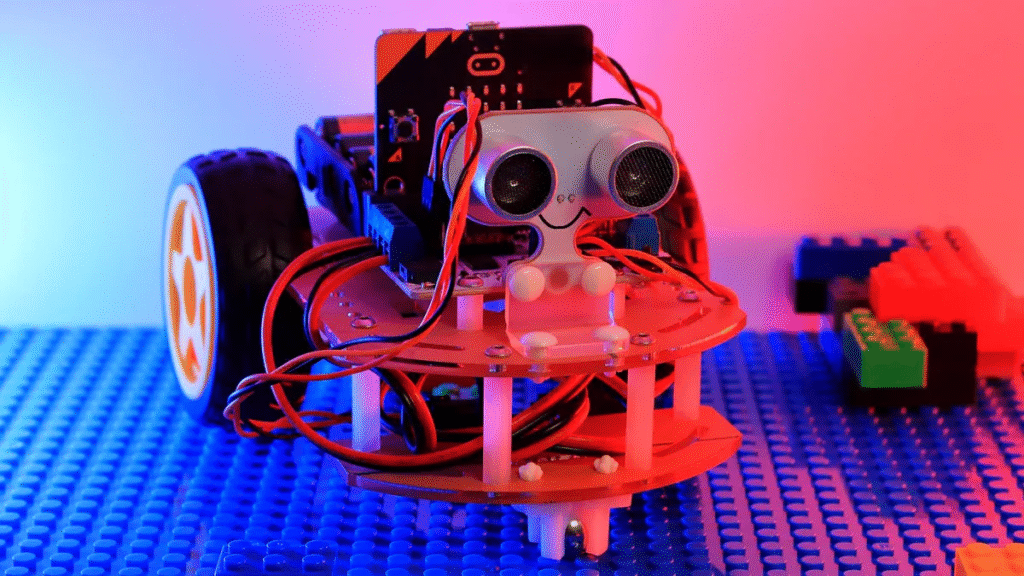

You may have heard the term “servo motor” in robotics or drone technology. A servo motor is a special type of motor that gives you precise control over movement. In robotics, you use servo motors to move arms, grippers, or even legs with accuracy and speed. In drones, these motors help stabilize cameras on gimbals, so you get smooth and steady shots even when the drone moves. This level of control makes servo motors important for tasks that need exact positioning.

Note: Servo motors stand out because they use a feedback system. This system checks the motor’s position and makes corrections if needed. Unlike stepper motors, which can lose their place under heavy loads, servo motors keep their position and deliver steady power. This makes them reliable for high-speed and high-precision jobs.

How They Work

A servo motor works by turning electrical signals into controlled movement. Inside the unit, you find a small DC motor, a potentiometer, and a control circuit. The potentiometer acts like a sensor, telling the control circuit the exact position of the motor shaft. When you send a signal to the servo, the control circuit compares the desired position to the current one. If the shaft is not in the right spot, the motor moves until it matches the signal.

The control circuit uses something called pulse width modulation (PWM) to decide how far and how fast the shaft should turn. The width of the pulse tells the servo where to move. Once the shaft reaches the target position, the motor stops, but the servo keeps checking its position and holds it steady. This feedback loop lets you achieve accurate and repeatable movements, which is why servo motors are so useful in drones and other electronic devices.

Servo Motors in Drones

、

Types of Servo Motors

You will find several types of servo motors used in drones. Each type has its own features and best use cases. The main types include analog, digital, and hybrid servo motors. These motors combine a DC motor, a driver, and an encoder. This setup gives you high precision and fast response, which is important for drone control.

Here is a table that compares the main types:

| Servo Motor Type | Feedback Mechanism | Precision | Cost | Controller Requirement | Typical Use Case in Drones |

|---|---|---|---|---|---|

| Analog | Optical sensor (LED + phototransistor) | Low | Low | Requires external controller | Low-cost applications, less precision needed |

| Digital | Optical sensor (LED + phototransistor) | High | Higher | No external controller needed | High-precision tasks, most common in drones |

| Hybrid | Potentiometer + optical sensor | Medium | Medium | Requires external controller | Medium precision applications |

Digital servo motors are the most common in drones. They offer better accuracy and faster response than analog types. Hybrid servos balance cost and performance for tasks that do not need the highest precision.

Main Applications

You will see servo motors in many parts of a drone. These motors help you control and adjust different components during flight. Here are some of the main applications:

- Flight Control Surfaces: Servo motors move the rudder, elevator, and ailerons. These parts help you steer the drone and keep it stable in the air.

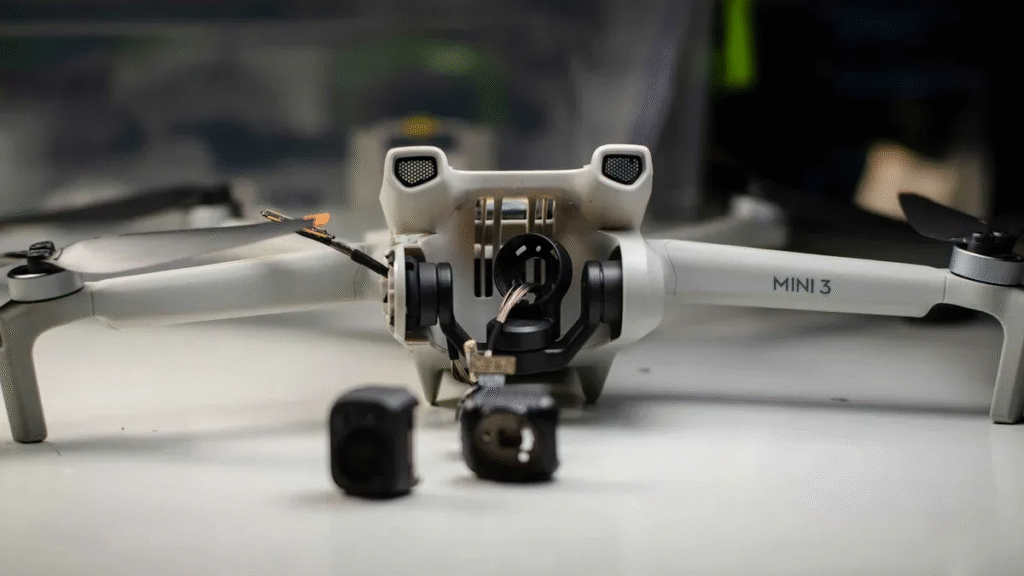

- Camera Gimbals: Servos control the rotation and tilt of cameras. This lets you capture smooth and steady images or videos, even when the drone moves.

- Payload Mechanisms: Some drones use servo motors to release or deploy items, such as sensors or small packages.

- Special Actuators: You might find servos in devices that throw objects or lock aprons for safety.

Tip: Servo motors use feedback systems like encoders or potentiometers. These systems send real-time data to the controller, which adjusts the motor’s position. This closed-loop feedback gives you precise and repeatable movements, which is key for stable flight and accurate camera work.

Military drones use servo motors for advanced tasks. They control flight surfaces, stabilize gimbals for sensors or weapons, and manage payloads. In consumer drones, servos help with camera stabilization and basic flight control. Both types rely on the feedback system to keep movements accurate and reliable.

Benefits and Limitations

Servo motors bring many benefits to drone design, but you should also know their limits.

Benefits:

- High precision control through closed-loop feedback. This helps you achieve accurate and repeatable positioning.

- Fast response and high torque-to-inertia ratio. You get agile and smooth movements, which is important for gimbal stabilization.

- Quiet operation. This is useful when you need to reduce noise, such as in wildlife monitoring.

- Consistent torque and speed under changing loads. This makes your drone more reliable in different conditions.

- Smooth running and high reliability. You will notice less vibration and lower maintenance needs.

- Advanced torque control. This allows your drone to adapt to different tasks and stay stable during flight.

Limitations:

- Added weight. Servo motors and their drives increase the drone’s weight, which can reduce flight time and payload capacity.

- Power consumption. Servos need continuous adjustment, which uses more battery power.

- Higher cost. Precision servo motors are more expensive than other types.

- Limited rotation range. Most standard servos can only turn about 180°, which may not fit every application.

- Increased complexity. You need extra control circuits and careful tuning for best performance.

- Environmental challenges. Servos must work well in different weather and conditions, which can be hard to achieve.

Note: When you add weight to a drone, such as with servo motors, you reduce flight time. Even a small increase in weight can have a big effect on how long your drone can stay in the air.

You must balance precision, power needs, cost, and battery life when choosing servo motors for your drone. This balance is especially important as drones become smaller, smarter, and more complex.

Servo Motors vs. Other Motors

Comparison

When you look at drone motors, you will see three main types: servo motors, brushless motors, and coreless motors. Each type has its own strengths and best uses. Servo motors give you precise control over position and movement. They use a feedback system, so you can make small, accurate adjustments. Brushless motors, on the other hand, use electronic commutation and sensors like Hall sensors or encoders. This design lets you control torque, speed, and position with high accuracy. Brushless motors are also smaller, lighter, and more efficient than brushed motors. They can reach very tight position control, sometimes as fine as ±0.004°, which is important for stable drone flight.

Coreless motors remove the iron core from the rotor. This makes them lighter and reduces inertia. You get better efficiency and longer battery life. Coreless motors work well for continuous, high-speed operation and have a high power-to-weight ratio. They also need less maintenance.

Here is a table to help you compare:

| Motor Type | Precision & Control | Efficiency Level | Typical Use Case |

|---|---|---|---|

| Servo Motor | High, with feedback system | High | Camera gimbals, control surfaces |

| Brushless | Very high, fast response | Very high | Propulsion, heavy-lift, racing drones |

| Coreless | Moderate, fast speed | Improved | Small drones, lightweight applications |

Tip: Brushless motors are best for drone propulsion because they offer high efficiency, durability, and precise speed control. Servo motors are not used for propulsion but excel in subsystems that need exact movement.

When to Use Each

You should choose your motor based on what you want your drone to do. Use brushless motors for the main propellers. They give you the power, speed, and efficiency needed for flight. These motors handle heavy loads and long flight times. If you need to move a camera or control a small surface, servo motors are the right choice. They let you make quick, precise adjustments, which is perfect for camera stabilization or moving control surfaces.

Coreless motors work well in small, lightweight drones. They save energy and keep your drone light. You will find them in micro drones or toys where high speed and low weight matter most.

Note: Servo motors shine in tasks that need rapid, precise positioning and smooth motion. Their closed-loop control system helps your drone stay stable and respond quickly to changes.

Are Servo Motors Essential?

Drones That Use Servos

You will find that some drones rely on servo motors for specific, high-precision tasks. These motors play a key role in drones that need to move parts with accuracy. For example, you might see them in drones that retract landing gear. This feature helps improve camera sightlines, reduces drag, and makes the drone look better in the air. Drones that carry cameras often use servo motors in gimbals. The gimbal keeps the camera steady, even when the drone shakes or faces strong wind. This stability is important for aerial photography, videography, and surveillance.

Many drones also use servo motors to control payload release. This allows you to drop supplies or deliver packages with great precision. You will see this in search-and-rescue, agriculture, and military drones. These examples show that servo motors are essential for drones that need reliable and precise movement.

Tip: If your drone needs to move or stabilize a part with accuracy, you should consider using servo motors.

Drones Without Servos

Not all drones need servo motors. Many popular multirotor drones, like quadcopters, do not use them at all. These drones use fixed-pitch rotors. The angle of the blades stays the same during flight. You control the drone by changing the speed of each rotor. The flight controller uses sensors, such as gyroscopes and accelerometers, to keep the drone stable. It balances the drone by adjusting motor speeds, not by moving parts with servos.

You will notice that quadcopters and similar drones do not have tilting rotors. Their symmetrical design and control system make servo motors unnecessary. Instead, they use advanced control algorithms to achieve precise movement. Coreless and brushless motors help by allowing quick changes in speed. This setup gives you sharp turns, fast stops, and smooth flight without the need for servo motors.

Note: Tricopters are an exception. They use a yaw servo to tilt the rear rotor for turning. Most other multirotors rely only on electronic speed control.

You have seen that not every drone needs servo motors, but many rely on them for precise control. When you compare motor types, you notice key differences:

| Motor Type | Rotation | Position Control | Price Range |

|---|---|---|---|

| Servo Motors | Limited | Closed-Loop | Low |

| Brushless DC | Continuous | Closed-Loop | Medium |

| Brushed DC | Continuous | Open-Loop | Low |

| Stepper | Continuous | Open-Loop | Medium |

Growing demand for lightweight, reliable motors drives innovation. If you want to learn more, companies like Hitec and Vertiq offer guides and support for drone motor integration.

FAQ

Do all drones need servo motors?

No, not all drones need servo motors. Many quadcopters use only brushless motors for flight. You will find servo motors in drones that require precise movement, such as camera gimbals or retractable landing gear.

Can you replace a servo motor with a brushless motor?

You cannot directly replace a servo motor with a brushless motor. Servo motors provide precise position control. Brushless motors work best for continuous rotation and propulsion. Each motor type serves a different purpose in drone design.

How do you know if your drone uses servo motors?

You can check your drone’s manual or look for moving parts like camera gimbals, control surfaces, or landing gear. If you see these features, your drone likely uses servo motors for precise movement.

What maintenance do servo motors need in drones?

You should keep servo motors clean and dry. Check for loose wires or connectors. Listen for unusual noises during operation. Regular inspection helps you catch problems early and keeps your drone running smoothly.