You will find that most drones rely on DC motors, especially brushless DC motors. These motors run on direct current, but electronic commutation makes them work in a way similar to AC motors. When you look at a drone motor, you might notice this unique blend of DC power and AC-like operation. Choosing the right motor type affects how your drone performs and how much maintenance you need.

Key Takeaways

- Most drones use brushless DC motors because they are light, efficient, and easy to control with batteries.

- Brushless motors last longer, need less maintenance, and provide smoother, quieter flight than brushed or AC motors.

- Brushed motors are cheaper and simpler but wear out quickly and suit only beginner or toy drones.

- AC motors are heavy, need extra parts, and respond slowly, making them unsuitable for battery-powered drones.

- Check your drone’s motor type by looking for three wires and an electronic speed controller for brushless motors.

AC vs DC Motors

How AC Motors Work

AC motors use alternating current to create motion. When you power an AC motor, the current flows through coils in the stator. This creates a rotating magnetic field. The rotor, which sits inside the stator, follows this field and spins. Many AC motors, like those in factories, run best at constant speeds. Some advanced types, such as brushless DC (BLDC) motors, use electronic commutation. This means they switch the current electronically instead of using brushes. You get less wear and tear, which leads to longer life and less maintenance.

Note: BLDC motors use electronic controllers to manage the timing of current. This allows for precise speed and torque control, which is important for drones.

Here is a quick comparison of AC and DC motors:

| Feature | AC Motors | DC Motors (including Brushless DC) |

|---|---|---|

| Power Source | Operate on alternating current (AC) from mains | Operate on direct current (DC), often from batteries |

| Speed Control | Speed adjusted via input frequency (VFD needed) | Precise and smooth speed control by varying voltage/current |

| Efficiency | High efficiency at constant speeds | Higher efficiency at variable speeds, especially BLDC types |

| Maintenance | Lower maintenance, no brushes or commutators | Brushed types require maintenance; BLDC reduces this issue |

| Size and Weight | Bulkier and heavier | Compact and lightweight, favorable for portable devices like drones |

| Application Fit | Better for constant speed, industrial uses | Preferred for battery-powered, variable speed, lightweight applications like drones |

How DC Motors Work

DC motors run on direct current, which you usually get from batteries. In a brushed DC motor, brushes and a commutator switch the current direction in the rotor. This keeps the rotor spinning. Brushless DC motors, which are common in drones, use electronic controllers instead of brushes. The controller switches the current in the stator windings. This creates a rotating magnetic field that spins the rotor.

Coreless DC motors remove the iron core from the rotor. This makes them lighter and more efficient. You get quick and precise control, which is perfect for drone flight. Electronic speed controllers (ESCs) connect the battery, flight controller, and motors. ESCs convert DC battery power into the three-phase AC that brushless motors need. This setup lets you adjust each motor’s speed independently, which is key for stable and responsive drone movement.

Why DC for Drones

You need a motor that is light, efficient, and easy to control for a drone. DC motors, especially brushless types, fit these needs. They work directly with batteries, which power most drones. You can control their speed smoothly by changing the voltage or current. This gives you precise control over each propeller.

Although AC motors often last longer and run cooler, they are bulky and need a steady AC power source. This makes them impractical for drones, which must stay light and run on batteries. DC motors, on the other hand, offer better speed control and quick response. This is essential for flight stability and maneuverability.

Tip: Brushless DC motors use electronic commutation, which combines the best features of AC and DC motors. You get high efficiency, low maintenance, and precise control—all important for drone performance.

When you choose a drone motor, you benefit from the compact size, low weight, and excellent control that DC motors provide. This is why almost every modern drone uses a brushless DC motor system.

DC Drone Motor Types

Brushed Motors

You will often find brushed motors in entry-level drones and toy models. These motors use brushes and a commutator to switch the direction of current inside the motor. The design is simple and low-cost, making it easy for you to replace or repair them. Brushed motors do not need a controller to operate, so you can connect them directly to a battery.

However, brushed motors have several drawbacks. The brushes and commutator wear out quickly, which means you need to replace them often. They also create more noise and electrical interference because of the constant contact between the brushes and the commutator. Brushed motors usually last only a few hours of flight time before performance drops. Their efficiency is lower, around 75-80%, and they generate more heat. These motors work best in small, lightweight drones where cost matters more than performance.

Tip: If you want a drone for learning or simple indoor flying, a brushed drone motor can be a good start. Just remember that you may need to replace it sooner than other types.

Brushless Drone Motor

Brushless motors have become the standard for most modern drones. You will see them in racing drones, aerial photography drones, and even heavy-lift industrial models. Brushless motors use electronic speed controllers (ESCs) to switch the current electronically, so they do not need brushes or a commutator. This design reduces friction and wear, making the motor last much longer.

A brushless drone motor offers higher efficiency, usually between 85-90%. It can spin faster and provide more power and torque than a brushed motor. You get smoother and quieter operation, which helps with stable flight and better video quality. Brushless motors also handle heat better and require less maintenance. You can find different types of brushless motors, such as inrunner and outrunner designs, each suited for specific drone roles like racing, photography, or carrying heavy loads.

| Component | Brushed Motor Construction | Brushless Motor Construction |

|---|---|---|

| Stator | Contains permanent magnets | Contains multiple windings arranged in slots |

| Rotor | Wound coils connected to a segmented commutator | Equipped with permanent magnets |

| Commutation Method | Mechanical commutation via brushes and commutator | Electronic commutation managed by an external ESC |

| Brushes | Present; maintain electrical contact with commutator | Absent; replaced by electronic control |

| Friction & Wear | High due to brush-to-commutator contact | Reduced due to absence of brushes and commutator |

| Maintenance | Requires regular maintenance due to brush wear | Virtually maintenance-free |

| Efficiency & Lifespan | Lower efficiency and shorter lifespan due to friction and wear | Higher efficiency and longer lifespan due to reduced friction and electronic control |

Brushed vs Brushless

When you compare brushed and brushless motors, you will notice big differences in performance, durability, and cost. Brushed motors are cheaper and easier to use, but they wear out quickly and need frequent maintenance. You might use them in small, budget-friendly drones, but they cannot match the power or efficiency of brushless motors.

Brushless motors give you more power and a higher thrust-to-weight ratio. For example, racing drones with brushless motors can reach thrust-to-weight ratios as high as 13:1, while brushed motors rarely go above 2:1. This means your drone can accelerate faster, carry heavier loads, and fly longer on a single battery charge. Brushless motors also last much longer—sometimes tens of thousands of hours—because they do not have brushes that wear out.

Here is a quick comparison:

| Feature | Brushed Motor Characteristics | Brushless Motor Advantages in Drone Use |

|---|---|---|

| Lifetime | Shorter due to brush and commutator wear | Longer lifespan with minimal maintenance |

| Maintenance | Requires regular brush replacement | Minimal maintenance needed |

| Speed & Acceleration | Limited by brush contact and rotor inertia | Higher speeds and quicker acceleration |

| Efficiency | Lower due to friction and energy loss | Higher efficiency with less heat generation |

| Noise & Vibration | Higher mechanical and electrical noise | Lower noise and reduced torque ripple |

| Torque | Moderate | Higher torque enabled by electronic control |

| Cost | Lower upfront cost | Higher initial cost but better long-term value |

Note: If you want a drone that lasts longer, flies faster, and needs less maintenance, choose a brushless drone motor. Most high-performance drones use brushless motors for these reasons.

You can find many types of drone motors, each designed for a specific purpose:

- Brushed motors: Simple, low-cost, used in toys and beginner drones.

- Brushless motors: Used in racing, photography, and industrial drones.

- Heavy-lift motors: Built for drones that carry large payloads.

- Racing motors: High-speed, lightweight, and optimized for quick response.

- Mini drone motors: Small and light for indoor or micro drones.

- Permanent magnet synchronous motors: Advanced, efficient, and precise for professional drones.

Choosing the right drone motor depends on your needs. For most users, brushless motors offer the best mix of power, efficiency, and durability.

Benefits of Brushless Motors

Efficiency

You get more flight time and better performance from a brushless motor. These motors convert more electrical energy into mechanical power, so less energy turns into heat. This means your drone can fly longer on the same battery charge. Here are some reasons why brushless motors are so efficient:

- They do not have brushes, which reduces mechanical energy loss.

- High-quality materials and optimized winding designs help produce more torque with less heat.

- The motors are lightweight, which improves flight time and lets you carry heavier payloads.

- Efficient speed controllers use advanced algorithms to minimize energy loss.

- Less heat generation means the motor lasts longer and stays reliable.

When you use an efficient drone motor, you save battery power and extend your drone’s flight time. Efficient motors also help your drone stay cool and perform better during long flights.

Control

Brushless motors give you precise control over your drone. You can change speed and direction quickly, which helps you make sharp turns or hover in place. These motors respond fast to your commands because they use electronic commutation. This technology allows for smooth and accurate adjustments in speed and torque.

You will notice that your drone feels more stable and agile. The motor’s high torque and quick response let you perform rapid maneuvers. Advanced controllers use techniques like Field-Oriented Control (FOC) to regulate speed and torque with great accuracy. This means your drone can handle sudden changes in direction and maintain steady flight, even in windy conditions.

Maintenance

You spend less time on maintenance with brushless motors. These motors have fewer moving parts and no brushes to wear out. You do not need to replace brushes or worry about commutator wear. This makes brushless motors more reliable and cost-effective over time.

- No brushes mean no brush replacement or related maintenance.

- Fewer wearing parts lead to a longer service life.

- You may need specialized knowledge for electronic repairs, but these are rare.

- Brushless motors generally last much longer than brushed motors.

With a brushless drone motor, you enjoy longer service life and lower maintenance costs. This lets you focus on flying instead of fixing your drone.

Why Not AC Motors

Technical Barriers

You might wonder why you do not see AC motors in drones. The main reason comes from the way AC motors work. AC motors need a steady supply of alternating current. Most drones use batteries, which provide direct current (DC). If you want to use an AC motor, you need extra electronics to convert DC from the battery into AC. This process adds weight and complexity to your drone.

AC motors also need special controllers called inverters. These controllers are larger and heavier than the electronic speed controllers (ESCs) used with brushless DC motors. You want your drone to stay light and efficient. Heavy controllers make your drone harder to fly and reduce flight time.

Note: AC motors often run best at constant speeds. Drones need motors that can change speed quickly for stable flight and sharp maneuvers. AC motors cannot respond as fast as brushless DC motors.

Here is a quick comparison:

| Feature | AC Motor in Drones | Brushless DC Motor in Drones |

|---|---|---|

| Power Source | Needs AC (not from battery) | Uses DC (from battery) |

| Controller Size | Large and heavy | Small and lightweight |

| Speed Response | Slow | Fast |

| Efficiency | Lower in variable speed | High in variable speed |

Design Limits

You want your drone to be light, agile, and easy to control. AC motors do not fit these needs. They are usually bigger and heavier than DC motors. This extra weight makes your drone less efficient and harder to maneuver.

AC motors also create more heat. You would need larger cooling systems, which add even more weight. Most drone frames do not have space for these bulky parts. You want a compact design, and AC motors make this difficult.

- AC motors limit your drone’s flight time.

- They make your drone less responsive.

- You face more maintenance because of extra parts.

🚁 Tip: If you want the best performance, always choose brushless DC motors for your drone. They give you the right mix of power, control, and efficiency.

You can see why drone makers avoid AC motors. The technical and design limits make them a poor choice for modern drones. Brushless DC motors remain the top pick for almost every drone you will find today.

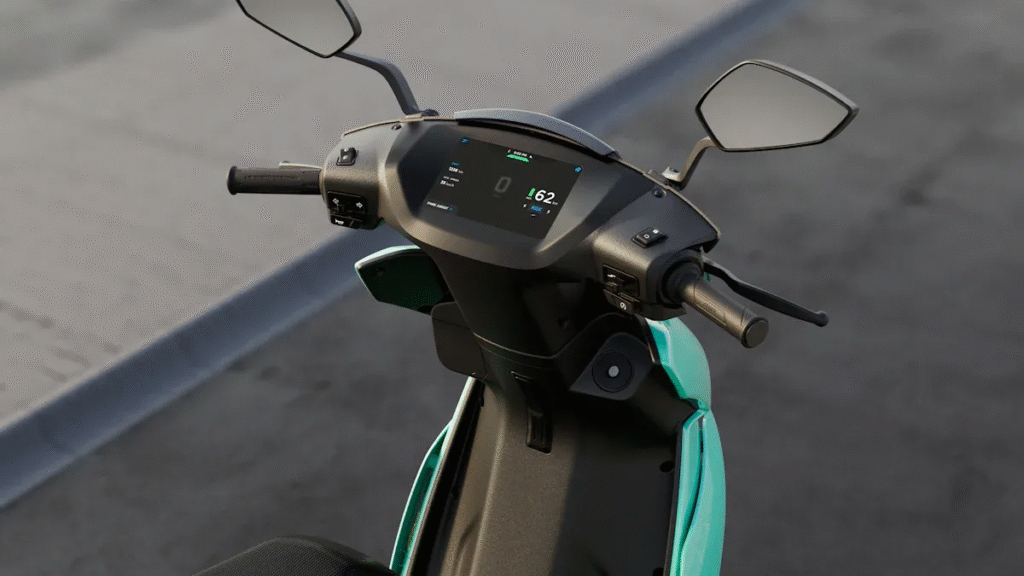

Identify Your Drone Motor

Visual Clues

You can often tell what type of motor your drone uses just by looking at it. Here are some signs to help you:

- Brushed motors usually have a metallic casing. You might spot small brushes and a commutator inside, which are parts that touch and wear down over time.

- Brushless motors look more compact. You will not see any brushes or commutators on the outside.

- Brushed motors often come with only two wires attached. These wires supply power directly to the motor.

- Brushless motors usually have three or more wires. These extra wires connect to an electronic speed controller (ESC) that manages the motor’s power.

- If you see a small electronic device near the motor, it is likely an ESC. This is a strong sign that your drone uses a brushless motor.

🛠️ Tip: If you want a motor that lasts longer and needs less maintenance, look for brushless motors with three wires and an ESC nearby.

Specs Check

You can also check your drone’s specifications to learn more about its motor. Follow these steps:

1. Find out if your drone uses a brushed or brushless motor. Brushless motors give you better efficiency and last longer. 2. Look at the KV rating. This number tells you how fast the motor spins for each volt of electricity. 3. Check your drone’s weight and size. Bigger drones need more powerful motors. 4. Think about how much weight your drone will carry. Make sure the motor can handle any extra load. 5. Calculate the thrust you need. Your motor should provide enough force to lift the drone and any payload. 6. Match the propeller size to the motor’s specs. The right match helps your drone fly smoothly. 7. Make sure your battery voltage fits the motor’s range. Using the wrong voltage can damage the motor. 8. Review the motor’s efficiency rating. Higher efficiency means longer flight times. 9. Confirm that the motor fits your drone’s frame. Check the mounting holes and size. 10. See how well the motor cools itself. Good cooling prevents overheating. 11. Check that your ESC matches the motor’s current needs. 12. Think about special needs, like quiet operation or quick response. 13. Test your setup before flying. This helps you catch any problems early.

🔍 Note: Always review your drone’s manual or product page for detailed motor specs. This helps you make the best choice for your flying needs.

You now know that most drones use brushless DC motors for their high efficiency, long lifespan, and low maintenance. These motors help your drone fly longer and handle tough jobs in fields like agriculture and media. When choosing a motor, check for features like good bearings, proper fit, and the right propeller size.

- Always inspect your motors for damage or dirt.

- Clean and oil bearings regularly.

- Replace worn parts to keep your drone reliable.

🛠️ Remember: The right motor choice and regular care keep your drone flying safely and smoothly.