Quadcopters require brushless DC motors (BLDC) for optimal performance. You might wonder why not use a brushed DC motor. Take a look at the main differences:

| Performance Aspect | Brushed DC Motors | Brushless DC Motors |

|---|---|---|

| Efficiency | Lower | Higher |

| Service Life | Shorter | Longer |

| Speed and Acceleration | Lower | Higher |

| Noise | Louder | Quieter |

Choosing the right motor helps your quadcopter fly longer, respond faster, and last much more.

Key Takeaways

- Brushless DC motors are the best choice for most quadcopters because they are more efficient, last longer, and run quieter than brushed motors.

- Choose motors with the right size and KV rating to match your quadcopter’s frame, propellers, and battery for better flight performance.

- Use a thrust-to-weight ratio between 2:1 and 3:1 to ensure your quadcopter lifts off easily and flies stably.

- Regularly inspect and maintain your brushless motors by cleaning and checking for damage to keep your quadcopter flying smoothly.

- Replace motors if you notice unusual noises, overheating, or loss of power to avoid crashes and keep your drone safe.

DC Motor Types

Brushed DC Motors

Brushed DC motors use a simple design. You will find brushes and a commutator inside. The brushes touch the spinning part of the motor, called the rotor, to deliver power. This contact causes friction, which leads to more heat and faster wear. Brushed motors usually have lower efficiency, around 75-80%. You need to replace the brushes after some time because they wear out. These motors also make more noise due to the friction between the brushes and the commutator.

You might see brushed DC motors in small or nano quadcopters. These tiny drones do not need much power, so the simple and cheap design works well. However, brushed motors do not last as long and need more maintenance. They also cannot deliver the quick speed changes that larger quadcopters require.

Brushless DC Motors

Brushless DC motors, often called BLDC motors, use a different design. They have a stationary part called the stator and a spinning part called the rotor, which holds magnets. There are no brushes, so you avoid friction and wear. This design gives you higher efficiency—often 85-90% or more. Brushless motors also run cooler and quieter. You get longer flight times and less maintenance.

| Feature | Brushed DC Motor | Brushless DC Motor |

|---|---|---|

| Structure | Brushes & Commutator | Stator & Rotor Magnets |

| Efficiency | 75-80% | 85-96.5% |

| Maintenance | High | Low |

| Noise | Higher | Lower |

| Typical Use | Nano quadcopters | Most quadcopters |

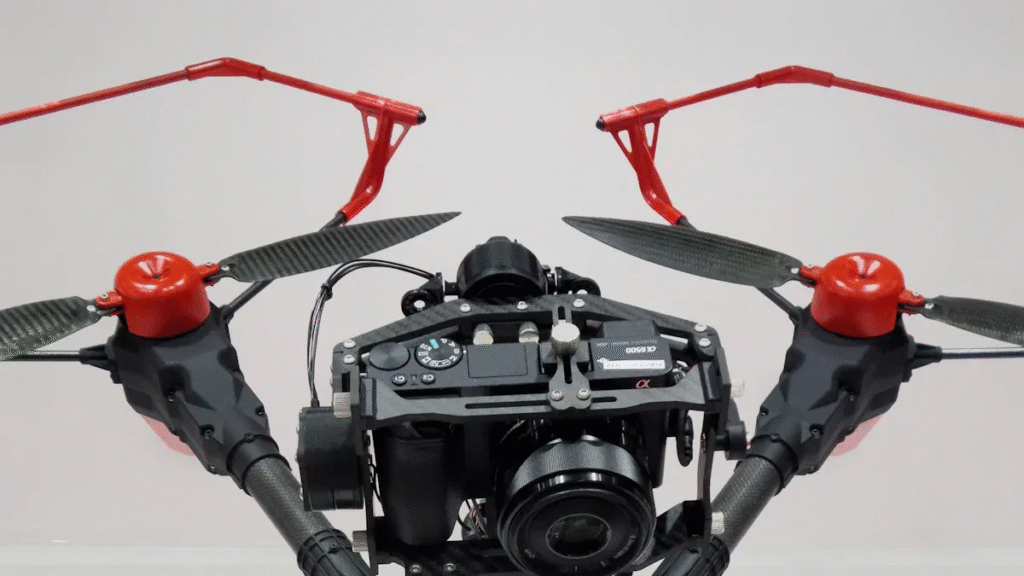

You will find brushless DC motors in almost all modern quadcopters. Their high power-to-weight ratio and precise speed control make them ideal for flight. Outrunner brushless motors can change propeller speed quickly, which helps your quadcopter stay stable and agile. The lack of brushes means less noise and a longer lifespan. For these reasons, brushless DC motors are the top choice for most quadcopter designs.

Tip: If you want a quiet, efficient, and long-lasting quadcopter, choose brushless DC motors. Nano drones may use brushed motors, but for anything larger, brushless is the way to go.

Why Choose Brushless DC Motors

Power and Efficiency

You want your quadcopter to fly longer and use less battery power. Brushless DC motors help you achieve this goal. These motors offer a higher power-to-weight ratio than brushed motors. This means you get more thrust without adding extra weight. The design of a brushless DC motor reduces friction and energy loss, so more of the battery’s energy goes directly into spinning the propellers.

Experimental data shows that a brushless DC motor, such as a 700 KV model, can reach efficiencies of about 62-64%. When you pair these motors with higher capacity batteries, like a 6000 mAh battery instead of a 3300 mAh one, you use less current and reach higher speeds. This combination lets your quadcopter carry more weight and stay in the air longer. Efficient motors also mean you do not have to recharge as often, which is great for longer flights or carrying cameras and sensors.

Note: The latest brushless DC motors use advanced designs, like coreless technology and permanent magnet synchronous motors. These features make your quadcopter even more responsive and extend flight time.

Durability and Maintenance

Brushless DC motors last much longer than brushed motors. The main reason is simple: they have no brushes that wear out. In a brushed motor, the brushes and commutator rub against each other, causing friction and heat. This leads to quick wear and frequent replacements.

Take a look at the difference in lifespan:

| Motor Type | Typical Lifespan in Quadcopter Use | Reason for Lifespan Difference |

|---|---|---|

| Brushed DC Motor | About 6 hours of flight time | Brushes wear down due to friction and commutator wear |

| Brushless DC Motor | Significantly longer | No brushes, less friction; durability limited by magnets/coils |

You will spend less time and money on repairs if you use brushless motors. Here are some key points about maintenance:

- Brushless motors have fewer moving parts and no brushes, so you do not need to replace worn-out parts often.

- Brushed motors need regular maintenance because the brushes and commutator wear out.

- Brushless motors are more reliable and cost-effective over time, even if they cost more at first.

You can trust a brushless DC motor to keep your quadcopter running smoothly for many flights.

Flight Performance

Flight stability and maneuverability matter a lot for quadcopters. Brushless DC motors give you the control and power you need for smooth, stable, and agile flight. Here’s how they help:

- The compact and lightweight design improves balance and lets you carry more payload.

- High efficiency and stable power output mean your quadcopter responds quickly to your commands.

- Electronic speed controllers (ESCs) work with brushless motors to provide precise speed and torque adjustments. ESCs take signals from the flight controller and turn them into three-phase power, letting you control each motor’s speed accurately.

- The combination of permanent magnets and electronic commutation ensures reliable operation, which is critical for stable flight.

ESCs play a key role in this system. They act as the bridge between your flight controller and the brushless DC motor. ESCs receive throttle commands and convert them into rapid power pulses that control the motor’s speed and direction. This precise control lets your quadcopter hover steadily, make sharp turns, and perform complex maneuvers.

Tip: If you want your quadcopter to fly smoothly and handle quick changes in direction, always choose brushless DC motors with quality ESCs.

Selecting the Right DC Motor

Choosing the right DC motor for your quadcopter means matching its specifications to your drone’s size, weight, and purpose. Let’s break down the key factors you need to consider.

Thrust-to-Weight Ratio

You want your quadcopter to lift off easily and stay stable in the air. The thrust-to-weight ratio tells you how much lifting power your motors provide compared to the total weight of your drone. For most quadcopters, aim for a thrust-to-weight ratio between 2:1 and 3:1. This means your motors should produce about twice as much thrust as your drone weighs. For example, if your quadcopter weighs 1 kg, your motors together should deliver at least 2 kg of thrust. Racing drones may need even higher ratios for quick acceleration, while larger or camera drones can fly with lower ratios if you limit their speed and maneuvers.

Tip: Use online tools like eCalc to calculate the best thrust-to-weight ratio for your build.

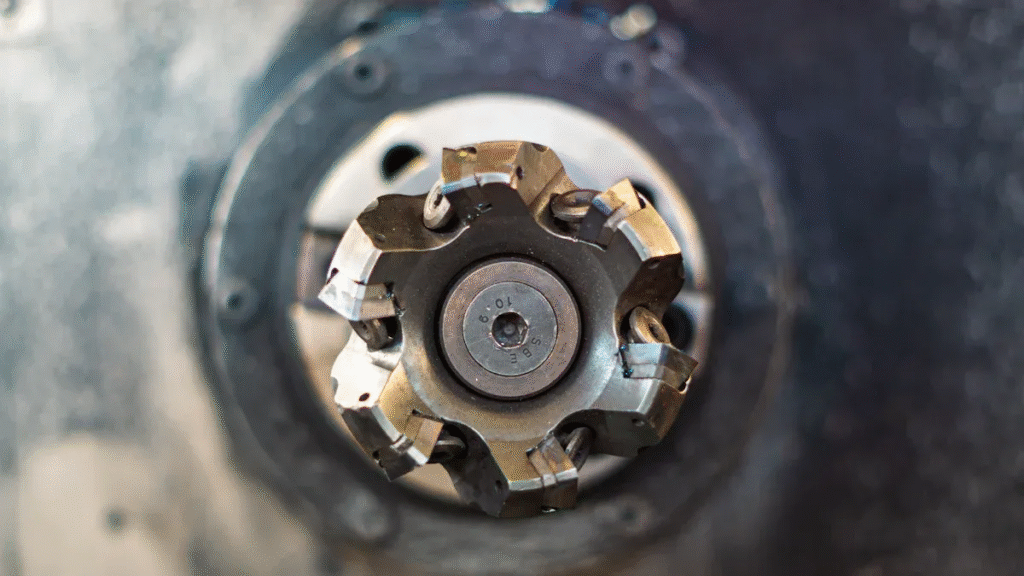

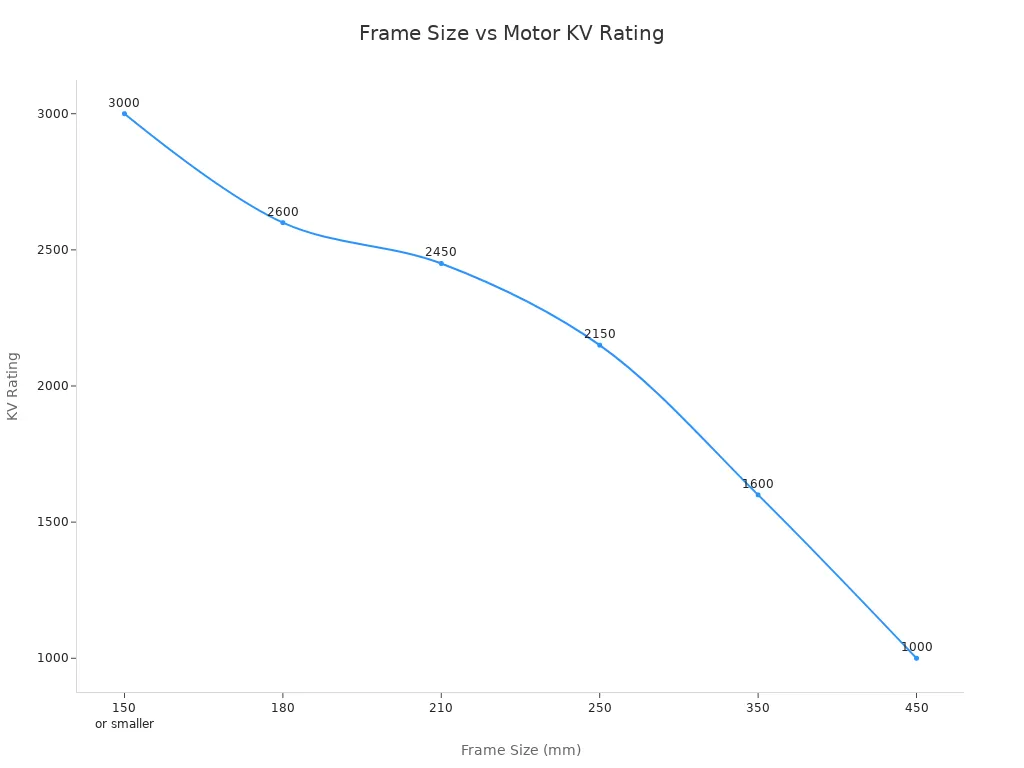

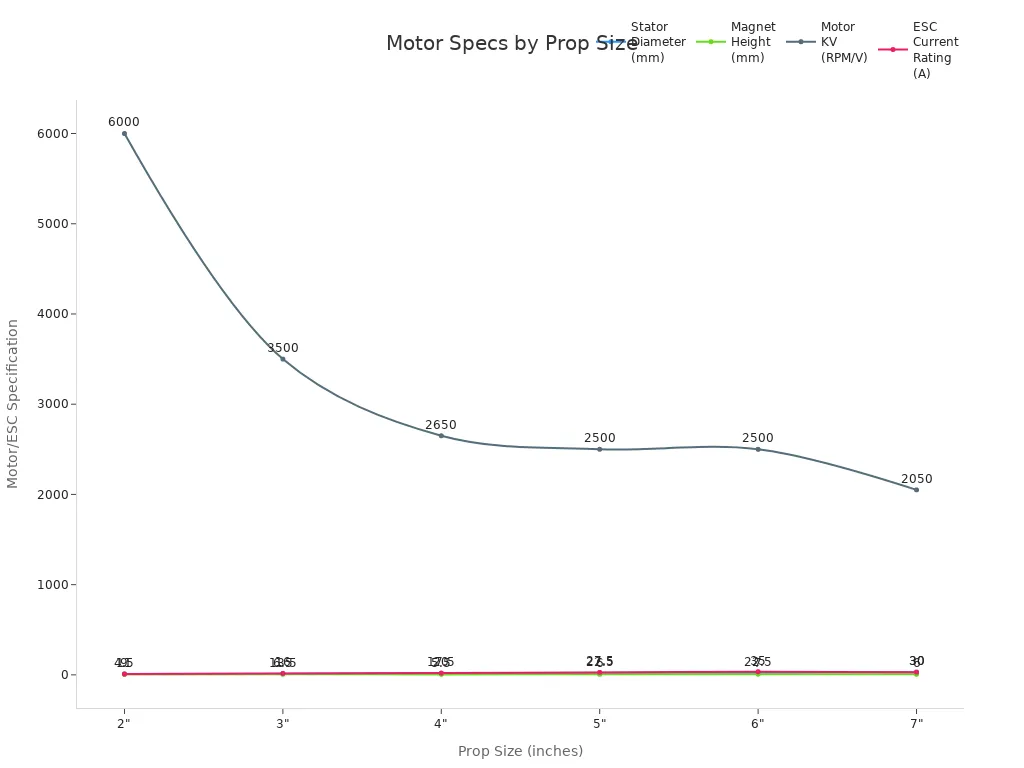

Motor Size and KV Rating

Motor size and KV rating affect how your quadcopter performs. The motor size (like 2204 or 2212) refers to the stator’s width and height. Larger motors create more torque, which helps lift heavier drones. The KV rating shows how fast the motor spins per volt. High KV motors spin faster but have less torque, making them good for small, light drones with small propellers. Low KV motors spin slower but provide more torque, which is better for bigger props and heavier drones.

Here’s a helpful table to match frame size, propeller, motor, and KV rating:

| Frame Size (mm) | Propeller Size (inch) | Motor Size | KV Rating |

|---|---|---|---|

| 150 or smaller | 3 or smaller | 1306 or less | 3000KV or higher |

| 180 | 4 | 1806 | 2600KV |

| 210 | 5 | 2204–2206 | 2300–2600KV |

| 250 | 6 | 2204–2206 | 2000–2300KV |

| 350 | 7 | 2208 | 1600KV |

| 450 | 8/9/10 | 2212 or larger | 1000KV or lower |

Propeller and ESC Compatibility

You must match your propellers and ESCs to your motors. The propeller’s bore size should fit the motor shaft. Use adapters if needed. Make sure you have two clockwise and two counterclockwise motors and props for stable flight. Your ESCs must handle the current your motors draw and work with your battery voltage. Brands like DJI and T-Motor offer matched sets for easy compatibility.

| Compatibility Aspect | Explanation |

|---|---|

| Mechanical Fit (Bore Size) | Propeller bore size must match the motor shaft size; adapters can be used if needed. |

| Rotational Direction (CW/CCW) | Use 2 clockwise and 2 counter-clockwise motors and props for balance. |

| ESC & Motor | ESCs must match motor specs for power and control. |

| Prop Size & Pitch | Larger props need more torque and power; smaller props spin faster. |

Weight Considerations

The weight of your motors affects how your quadcopter handles. Lighter motors help racing drones turn quickly and save battery life. Heavier motors can carry more, but they reduce agility. Always check that your frame can support the motor’s weight and mounting pattern. For racing, choose lightweight materials like aluminum. For heavy-lift or industrial drones, focus on durability and efficiency.

Remember: Test your setup with a thrust stand to measure real-world performance. Avoid common mistakes like using underpowered motors or mismatched ESCs, which can cause overheating or crashes.

Troubleshooting and Maintenance

Common Motor Issues

You may face several motor problems during your quadcopter’s life. Crashes often cause physical damage, such as ripped wires, bent shafts, or loose magnets. Overheating can happen if you use propellers that are too large or if your motors experience rapid RPM changes. Sometimes, using screws that are too long can create electrical shorts, which may lead to overheating or even burn out your motor. If you notice that one motor feels much hotter than the others, your quadcopter’s center of gravity might be off, making some motors work harder.

Here are some common issues you might encounter:

- Ripped wires or loose connections after a crash

- Bent motor shafts or damaged magnets

- Motors overheating from over-propping or rapid speed changes

- Electrical shorts caused by incorrect screw length

- Uneven motor temperatures due to balance problems

Tip: Always inspect your motors after a hard landing or crash to catch problems early.

Maintenance Tips

You can extend your brushless motor’s lifespan with regular care. Inspect your motors every three to six months for signs of wear, strange noises, or extra vibration. Clean the motor’s exterior and cooling fins to keep out dust, dirt, and moisture. Protect your motors from water, chemicals, and salt, which can cause corrosion. Check the bearings for grinding sounds or excess heat, and replace them if needed. Avoid overheating by keeping your motors cool and not overloading them. Using temperature sensors helps you spot abnormal heat before it causes damage.

Note: Every 10°C rise above the recommended temperature can cut your motor’s life in half. Keep your motors within safe limits for the best results.

When to Replace Motors

You should replace a motor if you notice any of these signs:

- Persistent grinding or rattling noises, even after cleaning

- Excessive vibration that does not go away

- Overheating that happens often, even with proper cooling

- Visible damage, such as bent shafts or cracked magnets

- Loss of power or inconsistent performance

If you keep up with inspections and cleaning, you will catch most problems before they get worse. Replacing worn or damaged motors keeps your quadcopter flying safely and smoothly.

You should choose brushless motors for most quadcopters because they offer better efficiency, longer lifespan, and smoother performance. When selecting a motor, focus on these key factors:

| Feature | Brushed DC Motor | Brushless DC Motor |

|---|---|---|

| Commutation | Mechanical brushes and commutator | Electronic commutation via ESC |

| Efficiency | 60-75% | 85-95% |

| Maintenance | Requires regular brush replacement | Minimal maintenance |

| Lifespan | Shorter due to brush wear | Longer lifespan |

| Noise & Vibration | Higher | Lower |

| Speed & Acceleration | Limited | Higher |

| Cost | Lower initial cost | Higher initial cost |

Before you decide, review this checklist:

- Match thrust-to-weight ratio for safe lift.

- Choose motor size and KV rating for your propeller and battery.

- Confirm ESC and frame compatibility.

Always consider your quadcopter’s size and what you want it to do for the best results.