Brushless motors power a wide variety of modern devices because they deliver high efficiency, strong reliability, and impressive versatility. Key application areas include industrial automation, transportation, home appliances, medical devices, consumer electronics, HVAC, and robotics. Retek Motion supplies advanced solutions for these demanding fields.

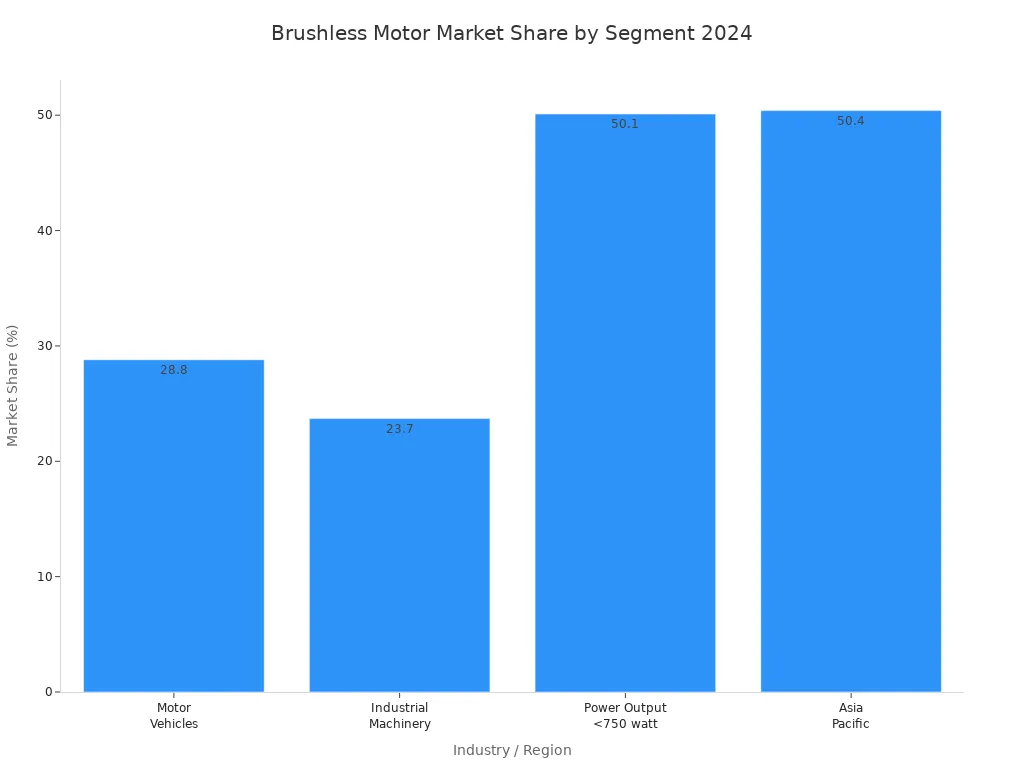

| Industry/Application Area | Key Devices/Uses | Market Share (2024) |

|---|---|---|

| Motor Vehicles (Automotive) | Automatic windows, HVAC, seats, wipers, doors | 28.8% |

| Industrial Machinery | Robotics, CNC machines, extruders, conveyors | >23.7% |

| Medical Sector | Dental tools, surgical instruments, lab equipment | N/A |

| Consumer Electronics & Automation | Energy-efficient motors for precise control | Included in overall market |

| Power Output <750 watt | Fans, pumps, compressors, home appliances, electric cars, HVAC, power tools, robots | 50.1% revenue share |

Key Takeaways

- Brushless motors power many devices because they are efficient, reliable, and versatile across industries like automotive, industrial machinery, medical devices, and consumer electronics.

- In industrial settings, brushless motors provide precise control, reduce maintenance, and last longer, making them ideal for machines, robotics, and automation.

- Electric vehicles, e-bikes, and scooters use brushless motors for better speed, quiet operation, and longer battery life, supporting cleaner and efficient transportation.

- Home appliances and power tools benefit from brushless motors by saving energy, running quietly, and lasting much longer than older motor types.

- Medical devices like ventilators and surgical tools rely on brushless motors for precise, quiet, and durable performance, improving patient care and device reliability.

Industrial Applications

Motion Control

Many industrial machines depend on precise motion control to operate efficiently. Brushless motors play a key role in these systems because they offer high accuracy, fast response, and low maintenance. Common equipment using these motors includes:

- Machine tools for cutting and forming

- Material handling systems and warehouse automation

- Packaging equipment

- Pumps and valves

- Robotics

- Security and access systems

- Vending and locker automation

- Agriculture machinery

- Autonomous guided vehicles (AGVs) and mobile robots (AMRs)

- Commercial food equipment

- HVLS fans

These motors use advanced electronic controllers and sensors to deliver smooth and stable speed regulation. This design reduces friction and wear, which means less downtime and longer service life. Retek Motion provides tailored solutions for OEMs and manufacturers who need reliable and efficient motion control.

Note: Brushless motors achieve higher precision and efficiency than brushed motors. Their electronic commutation allows for rapid and accurate adjustments, making them ideal for demanding industrial environments.

| Feature | Brushed Motors | Brushless Motors |

|---|---|---|

| Commutation | Mechanical, causes friction and wear | Electronic, enables precise current switching |

| Speed Regulation | Less precise, slower response | Highly precise, stable speed control |

| Efficiency | 75-80% | 85-90% |

| Lifetime | Shorter, more maintenance | Longer, less maintenance |

| Heat and Noise | More heat and noise | Less heat and quieter operation |

CNC Machines

CNC machines require motors that can deliver both speed and precision. Brushless DC motors are often used in CNC spindle drives, especially in high-end machines. These motors can reach spindle speeds up to 60,000 RPM, which improves productivity and surface finish quality. They also provide more torque, allowing the machine to cut tougher materials without losing accuracy. The lack of brushes means less vibration, lower maintenance, and a longer lifespan. Their compact size and high power density help manufacturers build smaller, more efficient machines. Retek Motion supports CNC manufacturers with motors that integrate easily into advanced control systems.

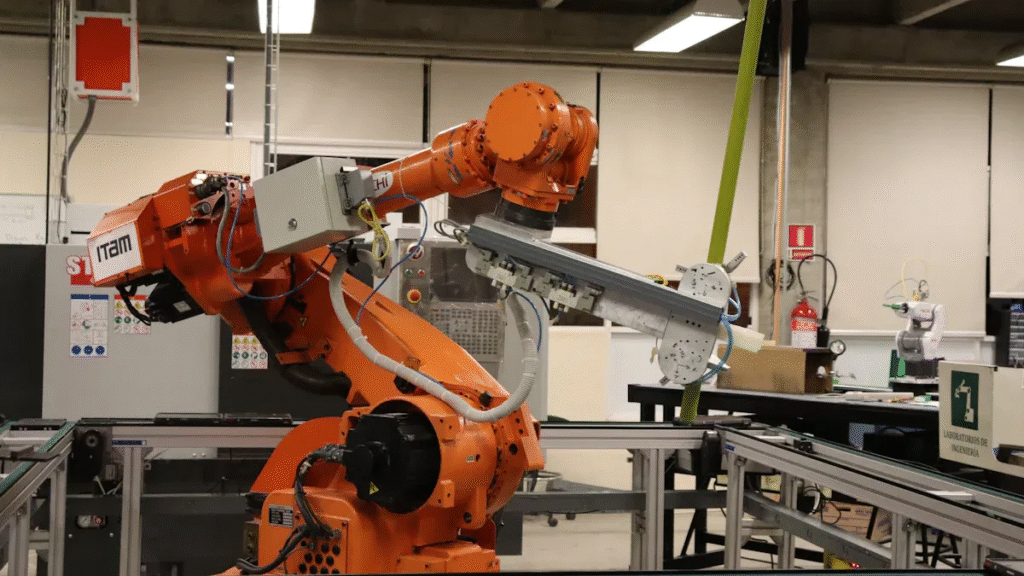

Robotics

Industrial robots rely on brushless motors for their durability and precise control. These motors power robots that perform delicate tasks in automated manufacturing, as well as equipment like conveyors and pumps. The main benefits include:

- Longer operational life due to reduced wear

- Less maintenance, which reduces downtime

- Higher efficiency with minimal energy loss

- Enhanced precision and responsiveness

- Compact size for space-saving designs

These features make brushless motors the preferred choice for high-performance robots. Retek Motion’s expertise ensures that robotic systems run smoothly and reliably, even in demanding industrial settings.

Transportation

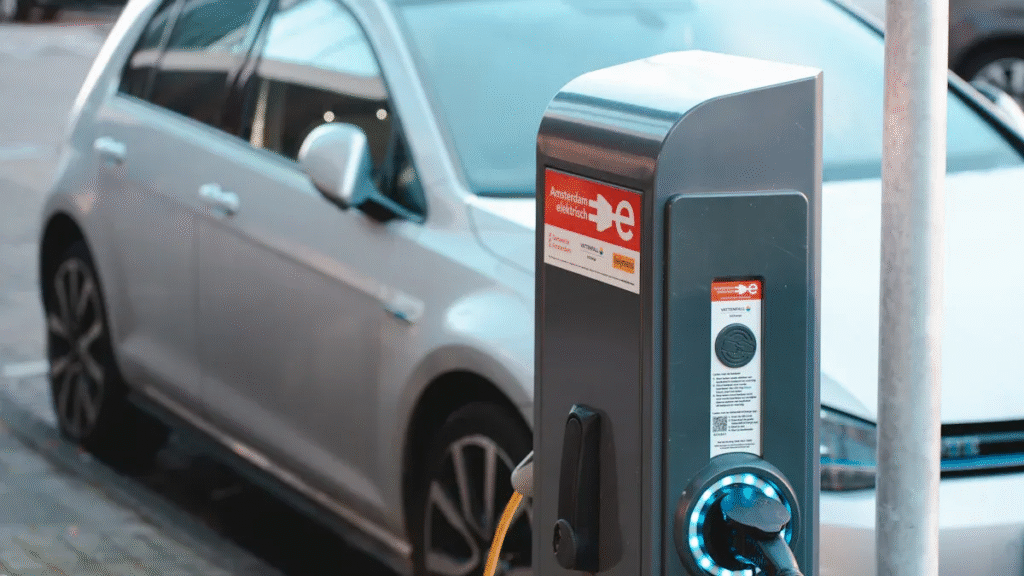

Electric Vehicles

Electric vehicles (EVs) rely on advanced motor technology to deliver smooth and efficient performance. Brushless motors now dominate the EV motor market, holding about 44% of the market share in 2024. These motors provide higher speed ranges, quiet operation, and fast dynamic response. Drivers benefit from better speed-to-torque ratios, high efficiency, and minimal maintenance. Major EV manufacturers choose brushless motors because they help vehicles accelerate quickly and operate quietly. Traditional internal combustion engine vehicles do not use electric motors for propulsion, which highlights a major difference between EVs and gasoline-powered cars. This shift marks a clear move toward cleaner and more efficient transportation.

E-Bikes and Scooters

E-bikes and electric scooters have become popular choices for urban mobility. Manufacturers prefer brushless DC motors for these vehicles because they offer several key advantages:

- Higher efficiency and longer range per charge

- Lower maintenance needs due to the absence of mechanical brushes

- Improved torque density for better acceleration and climbing ability

- Compact and lightweight design, which improves agility and aerodynamics

- Strong torque at low speeds, ideal for stop-and-go city travel

The Asia Pacific region leads the market for electric scooter motors, with rapid growth and major investments in research and development. Most new models use brushless DC motors, especially in the power segment under 1.5 kW. This trend supports the shift toward sustainable and efficient urban transportation.

Rail and AGVs

Rail transport and automated guided vehicles (AGVs) also benefit from brushless motor technology. In electric trains, motor controllers regulate traction motors for starting, stopping, maintaining speed, and regenerative braking. AGVs use these controllers to manage speed, movement, and energy use during material transport in warehouses and factories.

- Battery-powered mobile robots, including AGVs, achieve energy efficiency rates of 85–90% because of effective power conversion.

- Energy-optimized motion planning can reduce robotic energy consumption by 10–40%, making operations more sustainable.

These features help rail systems and AGVs operate reliably while saving energy and reducing costs.

Home and Consumer Devices

Appliances

Many modern home appliances now rely on advanced motor technology for better performance and energy savings. Brushless motors have become more common in household devices because they offer higher efficiency, longer service life, and lower maintenance compared to older brushed designs. These motors can last up to 20,000 hours, while brushed motors often last only 5,000 hours. Homeowners benefit from quieter operation and more precise control.

Common appliances featuring brushless motors include:

- Kitchen devices: mixers, juicers, coffee machines, rice cookers, food processors, electric knives, egg beaters, grain grinders, meat crushers

- Intelligent home devices: exhaust fans, circulating fans, humidifiers, dehumidifiers, air purifiers, electric doors and windows, smart door locks, soap dispensers, curtain systems

- Floor care: vacuum cleaners, carpet cleaners, handheld vacuums, floor grinders

- White goods: washing machines, air conditioners, refrigerators, dishwashers, microwave oven cooling fans, range hoods, tumble dryers, freezers

Manufacturers choose brushless motors for these products because they help save energy and improve reliability.

Power Tools

Power tools have seen a major shift toward brushless motor technology. Over 60% of consumers now prefer battery-powered cordless tools, which often use brushless motors for their efficiency and durability. These motors deliver up to 50% greater efficiency than brushed types, resulting in longer runtimes and less heat. Users experience less maintenance and longer tool life, making them ideal for demanding tasks.

- Popular power tools with brushless motors:

- Electric drills

- Angle grinders

- Handheld electric saws

- Portable power tools

Advances in battery technology and increased awareness of cordless tool benefits have driven this trend. Brushless motors support longer work sessions and reduce the need for frequent repairs.

Computer Peripherals

Brushless motors play a key role in computer peripherals, especially in devices that require quiet and reliable operation. Cooling fans in computers use these motors to provide low noise, high efficiency, and long life. Hard drives and CD-ROM drives also depend on brushless motors for precise disk rotation and minimal maintenance.

- Key benefits in computer peripherals:

- Quiet operation, ideal for noise-sensitive environments

- Compact size and longer lifespan

- Electronic control for speed variation and programmable features

These qualities make brushless motors essential for modern electronics, where performance and reliability matter most.

Medical Devices

Ventilators

Ventilators play a vital role in supporting patients who need help breathing. Many modern ventilators use advanced DC motors to drive high-speed micro-turbine blowers. These motors allow the ventilator to generate airflow and pressure without relying on a hospital’s compressed air supply. Key benefits include:

- High performance and long life, with some motors lasting over 15,000 hours.

- Quiet operation, which is important in medical settings.

- Speeds up to 60,000 RPM and rapid response due to low inertia designs.

- Precise control to match each patient’s breathing needs.

- Compact size and increased efficiency, allowing for smaller ventilators and batteries.

- Safe operation in high-oxygen environments.

These features make ventilators more reliable and portable. Patients can receive care in different settings, including during transport or at home.

Surgical Tools

Surgeons depend on reliable and precise tools for delicate procedures. Many surgical robots, shavers, debriders, morcellators, bone saws, drills, and high-speed handpieces use advanced DC motors. The main advantages in medical settings include:

- High efficiency, which supports battery-powered devices and reduces energy loss.

- Low maintenance and longer lifespan, since there are no brushes to wear out.

- Smooth and accurate control, critical for delicate surgical tasks.

- Quiet operation, which helps maintain a calm environment in the operating room.

- Compact design, allowing for smaller and lighter tools.

- Easy integration with modern control systems.

These tools are common in orthopedics, gynecology, ENT, dentistry, neurosurgery, and spine surgery. They help shorten treatment and recovery times, increase patient safety, and support minimally invasive procedures.

CPAP Machines

CPAP machines treat sleep apnea by delivering a steady stream of air to keep airways open during sleep. Advanced DC motors improve the performance and reliability of these machines. Notable features include:

- Low inertia rotors for high dynamic performance and quiet operation, even at speeds up to 90,000 RPM.

- Extended bearing life, often exceeding 30,000 hours.

- Low vibration and noise, which helps users sleep better.

- High efficiency, supporting continuous operation.

- Integrated controllers that precisely regulate airflow.

These qualities make CPAP machines more comfortable and effective for users, while also reducing the need for repairs.

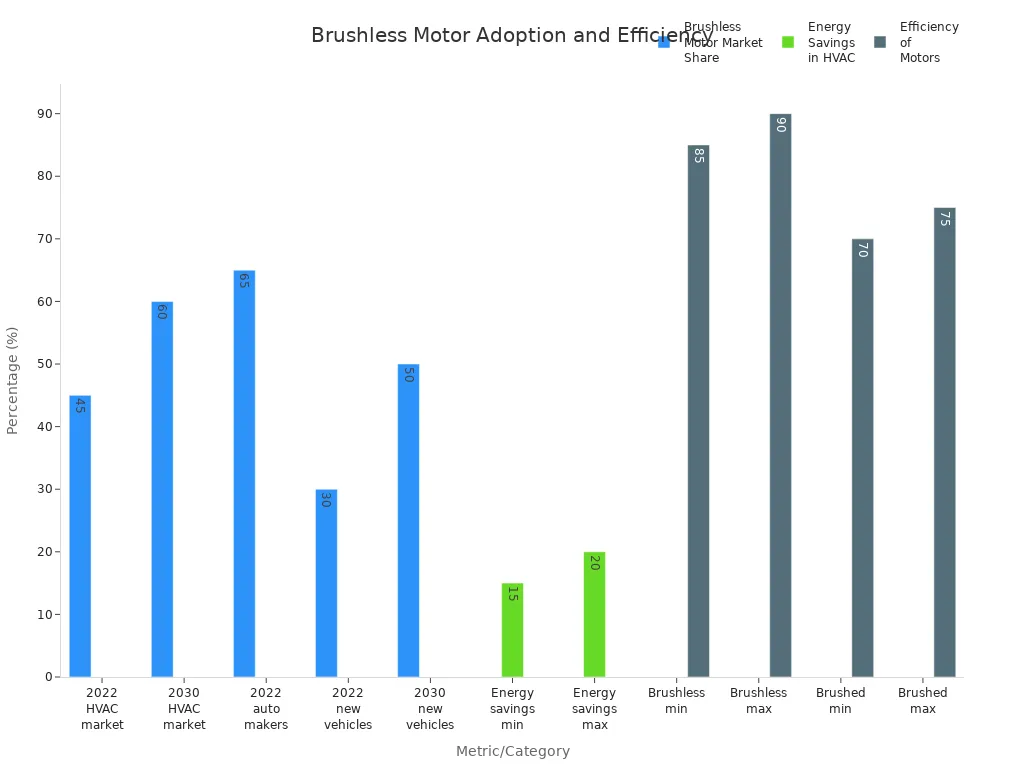

HVAC and Fans

Air Conditioners

Modern air conditioners rely on advanced motor technology to improve comfort and efficiency. Variable frequency technology, paired with electronically controlled motors, allows air conditioners to adjust speed and power based on cooling needs. This results in significant energy savings and quieter operation.

- Electronic commutation enables precise speed control, which reduces wasted energy.

- Smoother operation lowers mechanical noise, making indoor environments more comfortable.

- Most noise comes from internal components, but advanced motors help reduce it further.

Air conditioners with these motors can achieve up to 30% higher efficiency than those using traditional brushed motors. The U.S. Department of Energy reports that switching to high-efficiency motors can cut energy use by up to 30%. This leads to lower electricity bills and less strain on power grids.

Heat Pumps

Heat pumps use advanced motors to convert electrical energy into mechanical energy with minimal waste. These motors eliminate brushes, which reduces friction and heat. As a result, the system experiences less wear and lasts longer.

A table below highlights the main benefits and their impact on system longevity:

| Benefit Category | Explanation | Impact on Longevity |

|---|---|---|

| Reduced Mechanical Wear | No brushes, less friction | Longer lifespan, fewer repairs |

| Lower Heat Generation | Cooler operation | Prevents heat damage |

| Higher Efficiency | Better energy conversion | Less stress on components |

| Advanced Electronic Control | Precise speed and torque management | Reduces mechanical stress |

| Reduced Maintenance | Fewer wear parts | Lower costs, less downtime |

These features make heat pumps more reliable and cost-effective over time.

Blowers

Blowers in HVAC systems often use electronically commutated motors (ECMs), a type of advanced motor with integrated electronic controls. ECMs convert AC power to DC and manage speed electronically.

- ECMs provide precise variable speed control and maintain consistent airflow.

- They operate about 40% more efficiently than traditional permanent split capacitor (PSC) motors.

- ECMs produce less noise and vibration, which improves comfort in homes and vehicles.

- Their compact design allows for flexible installation in tight spaces.

The chart below shows the growing market share and efficiency gains of these motors in HVAC systems:

Brushless Motors in Robotics

Industrial Robots

Industrial robots depend on advanced motor technology for precise and reliable movement. Over 60% of robotic systems use brushless motors for motion control. These motors deliver high torque at low speeds, which is important for robotic joints and positioning systems. Electronic commutation and sensor feedback allow for accurate speed, torque, and position control. The absence of brushes reduces mechanical wear, leading to longer lifespans and less maintenance. Servomotors with brushless designs use closed-loop systems, which help robots perform stable and repeatable tasks. Factories use these robots in conveyor systems, automated assembly lines, and material handling. The high power density and compact size of brushless motors make them ideal for modern industrial robots.

Note: Regulatory agencies encourage the use of energy-efficient motors in robotics. This focus on sustainability and reliability drives the adoption of brushless technology in manufacturing.

Drones

Drones rely on brushless motors for propulsion and maneuverability. These motors provide strong torque, high efficiency, and precise speed control. The drone motor market reached about $1.5 billion in 2024 and is expected to grow rapidly. Inner rotor brushless motors hold over 60% of the market share because they offer a compact design and high power density. Drones benefit from longer service life, reduced maintenance, and quieter operation. These features support demanding uses such as aerial photography, racing, agriculture, and military applications. Technological advances, including AI integration and improved materials, continue to enhance drone performance.

| Segment/Category | Market Share / Value / Benefit | Explanation / Reasoning |

|---|---|---|

| Inner Rotor Segment | 60.9% market share | Preferred for higher power density and compact design |

| Power Output < 750W | 50.1% revenue share | Long operating life and high voltage tolerance |

| Efficiency | Often exceeds 80% | Superior efficiency compared to brushed motors |

| Key Benefits | Longer life, less maintenance, strong torque | Ideal for FPV racing, aerial photography, and industry |

Model Aircraft

Model aircraft use brushless motors to achieve high efficiency and reliable performance. These motors convert more electrical energy into motion, resulting in longer flight times and better payload capacity. The absence of brushes means less friction, quieter operation, and minimal maintenance. Model aircraft can fly faster and carry heavier loads because brushless motors generate more torque and allow for rapid acceleration. The table below compares brushless and brushed motors in model aircraft:

| Feature/Aspect | Brushless Motors | Brushed Motors |

|---|---|---|

| Efficiency | Higher, less energy loss | Lower, more friction |

| Lifespan | Longer, minimal maintenance | Shorter, brushes wear out |

| Noise Level | Quieter | Noisier |

| Torque and Speed | Superior control and acceleration | Consistent at lower speeds |

| Heat Generation | Less heat, longer operation | More heat, shorter operation |

| Flight Performance | Longer flight, better payload | Shorter flight, less reliable |

Tip: Miniaturization and smart motor controllers are making model aircraft even more efficient and easier to control.

Brushless motor technology has transformed many industries with its efficiency, precision, and reliability.

- High efficiency ratings, long life, and quiet operation support sensitive environments like hospitals and advanced manufacturing.

- In robotics and automation, these motors enable fast response and silent operation, powering collaborative robots and automated vehicles.

- The automotive sector leads adoption, while industrial automation and healthcare continue to grow. Retek Motion advances this field by offering high-quality, customizable solutions for both industrial and consumer needs. As technology improves, new applications and smarter systems will continue to emerge.