When you consider running a DC drone Motor nonstop, safety depends on the motor’s type, design, and upkeep. Brushless motors last longer and need less maintenance than brushed motors, which often fail due to worn brushes. Proper cooling, smart load management, and routine checks keep your equipment reliable. Retek Motion offers trusted solutions.

Key Takeaways

- Choose brushless DC motors for nonstop drone use because they last longer, run cooler, and need less maintenance than brushed motors.

- Keep your motor cool and clean by ensuring proper ventilation, avoiding overload, and regularly inspecting for dust, debris, or wear.

- Follow best practices like selecting motors with continuous duty ratings, matching motor specs to your drone, and scheduling regular downtime for checks to extend motor life and ensure safe operation.

DC drone Motor Risks

Overheating

Continuous operation puts your DC drone Motor at risk of overheating. When you run a motor 24/7, heat builds up quickly, especially if you push the motor beyond its rated voltage or current. Brushless DC motors often overheat due to overvoltage and overcurrent. High voltage increases iron losses, while high current is the main cause of heat. If you overload your drone or operate it at high speeds, the motor draws more power and generates more heat. Poor ventilation or blocked airflow makes the problem worse, trapping heat inside the motor housing.

Tip: Always check that your drone has proper cooling and that you do not exceed the recommended load or speed. Avoid running your DC drone Motor in dusty or humid environments, as these conditions can cause corrosion and clog the motor, leading to even more heat buildup.

Common overheating issues include:

- Overloading the motor with heavy payloads

- Running at high speeds for long periods

- Insufficient cooling or blocked vents

- Using the wrong voltage or current settings

- Confined spaces that trap heat

If you ignore these risks, your motor may fail suddenly, causing your drone to crash or lose power.

Wear and Tear

Mechanical wear is a major concern, especially for brushed DC drone Motors. Brushed motors use physical brushes and a commutator, which wear down over time. This wear leads to sparking, noise, and reduced performance. You might notice your motor making grinding or screeching sounds, or see a drop in power output. Excessive debris and worn brushes can cause the motor to stop working altogether.

| Sign or Indicator | Description |

|---|---|

| Excessive Sparking | Worn brushes or commutator damage from long use or poor maintenance. |

| Reduced Power Output | Motor struggles to deliver normal load performance. |

| Unusual Noises | Grinding or screeching sounds above 70 dB, signaling mechanical wear. |

| Brush Length Reduction | Brushes worn down to less than a quarter of original length need replacement. |

| Commutator Surface Damage | Dirt or damage on the commutator affects electrical contact and friction. |

| Debris Accumulation | Carbon debris buildup accelerates wear and causes electrical issues. |

| Brush Holder/Slip Ring Wear | Damage leads to poor brush contact and increased wear. |

| Spring Tension Loss | Reduced spring pressure causes rapid brush wear and poor contact. |

Brushless motors, on the other hand, do not have brushes or commutators. This design reduces mechanical wear, lowers maintenance needs, and extends the motor’s lifespan. If you want to run your drone continuously, brushless motors are the better choice.

Electrical Issues

Electrical failures can stop your DC drone Motor without warning. You may face problems like the motor not starting, unstable speed, or sudden overheating. These issues often result from unstable power supplies, controller failures, or wiring problems. Overloading the motor or using an underrated controller can also cause short circuits and rapid overheating.

- Motor may not start due to low or unstable voltage, controller failure, or wiring faults.

- Speed may become unstable if the controller cannot regulate power or if internal parts wear out.

- Overheating often results from long-term overload or poor cooling.

- Abnormal noises can signal rotor imbalance or damaged bearings.

Brushless motors use electronic commutation, which eliminates arcing and reduces electrical noise. This design provides smoother operation and less interference with sensitive drone electronics. Brushed motors, however, suffer from arcing, higher electrical noise, and more frequent maintenance.

| Feature | Brushed DC Motors | Brushless DC Motors |

|---|---|---|

| Electrical Switching | Mechanical via brushes and commutator, causes arcing and noise | Electronic switching, no arcing, less noise |

| Mechanical Wear | Brushes and commutator wear out, limiting lifespan | No moving electrical contacts, longer life |

| Maintenance | Requires regular brush replacement and cleaning | Minimal maintenance needed |

| Performance at High Speed | Brush arcing increases, limiting speed and reliability | Electronic commutation allows higher speeds and smoother operation |

Note: For continuous operation, always choose motors designed for continuous duty (S1 rating). Look for certifications like ISO 9001-2015 and RoHS, which ensure quality, safety, and environmental compliance. Motors built for continuous duty use thicker windings, larger bearings, and advanced controllers for better performance and durability.

Lifespan & Care

Motor Lifespan

Continuous operation puts any motor to the test. When you run a DC drone Motor around the clock, you need to consider how long it will last. Brushless motors stand out for their durability. Most brushless DC motors can operate for over 10,000 hours without major issues. Some even reach 25,000 hours or more. This is about five times longer than what you get from brushed motors. The main reason is simple: brushless motors do not have brushes that wear out. You avoid friction, sparking, and the constant need for replacements. Only the bearings limit the lifespan, so you get quieter and more reliable performance. If you want your drone to work nonstop, brushless motors are the best choice.

Several factors can shorten the life of your DC drone Motor during continuous use:

- High ambient temperatures above 40°C speed up power loss and motor wear.

- Vibration from mismatched propellers or poor mounting causes early failure.

- Incorrect motor parameters, such as the wrong KV rating or phase resistance, lead to overheating.

- Differences in phase resistance create extra heat, which can push the motor past safe temperature limits.

- Overpowered motors or mismatched loads add mechanical and thermal stress.

You should always select the right motor for your drone and monitor its environment to maximize lifespan.

Maintenance

Proper maintenance keeps your DC drone Motor running safely 24/7. You need to set up a regular inspection schedule. Check for dust, debris, and signs of wear. Clean the motor housing and cooling vents to prevent overheating. Avoid overloading the motor, as this puts extra stress on all components. Make sure your power supply stays stable and reliable. If you notice any strange noises, vibrations, or drops in performance, act quickly. Diagnose faults and repair them before they cause bigger problems.

Maintenance tips for extending motor life:

- Inspect and clean the motor and controller regularly.

- Avoid running the motor at maximum load for long periods.

- Keep the cooling system free of dust and blockages.

- Use professional repair services if you are unsure about a problem.

- Monitor the controller for signs of overheating or instability.

By following these steps, you reduce the risk of sudden failures and keep your drone in the air longer.

Cooling

Effective cooling is essential for any DC drone Motor that runs nonstop. Heavy-lift drone motors generate a lot of heat, so you need advanced cooling features. Look for motors with heat sinks, cooling fins, and well-designed airflow channels. These features help move heat away from the motor quickly. Some high-end motors use silver windings to cut heat generation by up to 30%. Waterproof and corrosion-resistant designs also help, especially if you fly in harsh environments.

You can use several cooling methods:

- Air cooling is simple and common, but it has limits because air does not carry heat away very well.

- Heat pipe technology offers better results. It moves heat quickly and keeps the motor at a safe temperature. Placing heat pipes at the bottom of the stator slot improves cooling even more.

- Composite air-heat pipe systems can lower winding temperatures by nearly 20 degrees Celsius and extend safe operation time by over 12%. This makes a big difference for continuous use.

Tip: Always keep cooling vents clear and check for dust or debris. If you operate in hot or humid conditions, consider motors with advanced cooling systems.

Retek Motion provides expert guidance and solutions for maximizing motor life and safety. Their products include motors designed for continuous duty, with advanced cooling and robust construction. By choosing the right equipment and following best practices, you ensure safe and reliable operation for your drone.

Best Practices

Duty Cycles

You should always select motors with an S1 duty cycle rating for continuous operation. This rating means the motor can run at its rated power, torque, and speed without overheating or suffering damage. The table below shows typical S1 duty cycle values:

| Parameter | Value | Explanation |

|---|---|---|

| Continuous duty cycle (S1) power | 120 W | Nominal power the motor can sustain continuously without overheating or damage. |

| Continuous duty cycle (S1) torque | 0.38 Nm | Nominal torque the motor can maintain indefinitely under load. |

| Continuous duty cycle (S1) speed | 315 rad/s | Nominal angular speed for continuous operation without risk of failure. |

Selecting a motor with the correct duty cycle ensures your DC drone Motor can handle nonstop use without thermal or mechanical failure.

Motor Selection

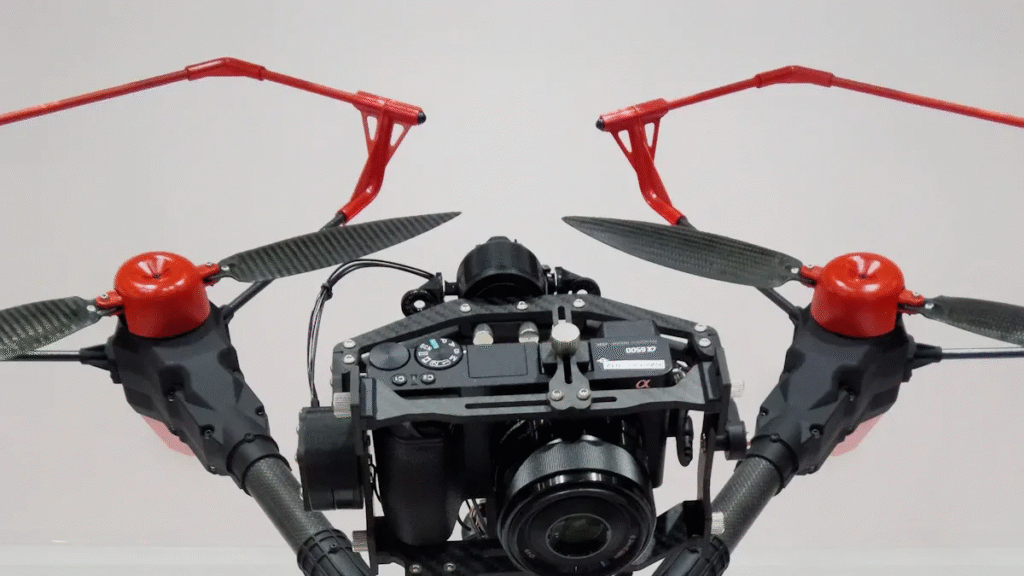

When you choose a motor for 24/7 drone use, brushless DC motors are the best option. Brushless motors last longer, need less maintenance, and run more efficiently than brushed motors. They also produce less heat and noise, which helps your drone perform better over time. You should match the motor’s KV rating and torque to your drone’s size and propeller. Make sure the voltage and current ratings fit your ESC and battery. Use quality bearings and secure mounting to avoid vibration and early wear. Retek Motion recommends using pre-made brushless motors from trusted brands for reliability and safety.

Tip: Always balance your propellers and check motor temperature during operation to prevent overheating.

Scheduled Downtime

Even with the best equipment, you should plan regular downtime and inspections. Continuous operation increases the risk of wear and hidden faults. Schedule short breaks to check for dust, debris, or signs of overheating. Clean and lubricate moving parts as needed. Monitor performance and record any changes in noise or vibration. These steps help you catch problems early and extend the life of your DC drone Motor.

For expert advice and high-quality motor options, consult Retek Motion. Their guidance and products help you achieve safe, reliable, and efficient continuous drone operation.

You can safely run your drone motor nonstop if you choose a brushless model, maintain it regularly, and use advanced cooling.

- Brushless motors offer high efficiency and low maintenance.

- Regular inspections and quality materials extend lifespan.

For reliable results, follow industry best practices and trust brands like Retek Motion.