Yes, brushless motors do wear out, but you will notice they last much longer than brushed motors. The absence of brushes means less friction and less noise. You mainly need to watch the bearings, as they are the most common part to wear down over time. Factors like heat, dirt, and overloading can shorten the lifespan.

Here’s why brushless motors have a reputation for durability:

- No brushes means minimal internal friction and less frequent maintenance.

- Bearings are the main parts that need attention.

- You get quieter and smoother operation, with lifespans often reaching 10,000 hours or more.

Key Takeaways

- Brushless motors last much longer than brushed motors because they have no brushes, which reduces friction and wear.

- Bearings are the main parts that wear out in brushless motors; keeping them clean and well-lubricated extends motor life.

- Overheating and harsh environments cause motor damage; avoid overload and keep motors cool and clean to prevent early wear.

- Regular inspections help spot early signs of wear like unusual noises, vibration, or overheating to prevent costly repairs.

- Following maintenance tips like cleaning, proper lubrication, and timely bearing replacement keeps brushless motors running smoothly for many years.

Brushless Motors vs. Brushed Motors

Design Differences

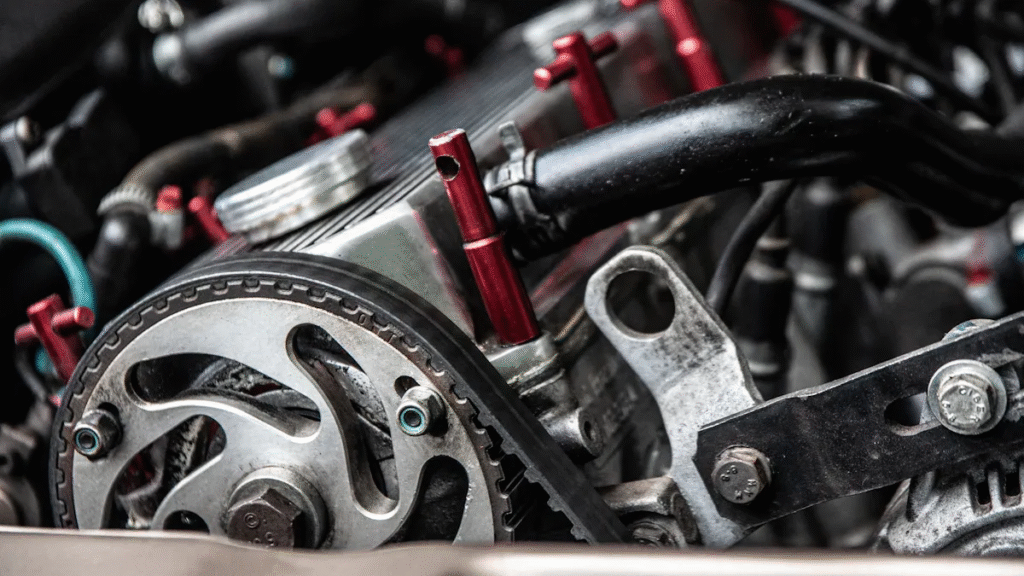

When you look inside a motor, you will see big differences between brushed and brushless types. Brushed motors use brushes and a commutator to switch the current in the spinning part, called the rotor. These brushes touch the commutator and create friction. Over time, this friction causes the brushes to wear out.

Brushless motors work in a different way. They use electronic sensors and controllers to switch the current. The rotor in a brushless motor has permanent magnets, while the stator has coils. You do not find brushes or a commutator in this design. This means less friction and fewer parts that can wear down.

Here is a table to help you compare the two:

| Feature | Brushed DC Motor | Brushless DC Motor |

|---|---|---|

| Rotor | Coils on iron core | Permanent magnets |

| Stator | Permanent magnets | Windings (coils) |

| Commutation | Mechanical (brushes and commutator) | Electronic (sensors and controllers) |

| Brushes | Present (wear out over time) | Absent |

| Maintenance | Needs regular maintenance | Needs little maintenance |

Wear and Lifespan

You will notice that brushless motors last much longer than brushed motors. The main reason is the lack of brushes. In brushed motors, the brushes and commutator wear out after 2,000 to 5,000 hours of use. You will need to replace them to keep the motor running.

Brushless motors can run for over 10,000 hours because they do not have brushes to wear out. The main part that wears in a brushless motor is the bearing. If you keep the motor clean and avoid overloading it, you can expect a long service life.

Brushless motors also run more efficiently. They waste less energy as heat and make less noise. You get smoother operation and higher speeds. This makes them a better choice for many modern machines.

Causes of Wear

Bearings

Bearings are the main part in brushless motors that wear out over time. You rely on bearings to keep the motor spinning smoothly. When bearings start to fail, you may hear grinding noises or feel extra vibration. The quality and type of bearing make a big difference in how long your motor lasts.

Here is a table showing how different bearing features affect motor lifespan and performance:

| Bearing Aspect | Influence on Motor Lifespan and Performance |

|---|---|

| Precision Grades (G0/P0 to G3/P4) | Higher precision bearings with tighter tolerances reduce heat and wear, extending motor life. |

| Radial and Axial Clearance (C0, C2, C3, etc.) | Appropriate clearance reduces heat generation and accommodates thermal expansion, improving lifespan. |

| Material and Heat Treatment | High-quality bearing steels and proper heat treatment enhance wear resistance and shock absorption, increasing durability. |

| Lubrication and Grease Life | Proper lubrication and grease quality directly affect bearing life and motor operating temperature. |

| Noise and Vibration Ratings | Lower noise and vibration levels indicate better bearing quality, reducing wear and extending motor life. |

| Fit and Mounting Tolerances | Correct shaft and housing fits ensure proper preload, minimizing slippage and premature failure. |

Manufacturers often state that the rated lifespan of a brushless motor depends mostly on the bearings. For example, certified bearings from brands like NMB and NSK can last 100-200 hours under tough conditions, but regular inspection and timely replacement help prevent sudden failures. If you keep bearings clean and well-lubricated, you can avoid many common problems.

Tip: Listen for unusual noises and check for extra vibration. These signs often mean the bearings need attention.

Heat and Overheating

Heat is another major cause of wear in brushless motors. When your motor runs too hot, its parts break down faster. Every 10°C (about 18°F) above the recommended temperature can cut the motor’s life in half. If the temperature gets too high, the magnets inside the motor can lose their strength forever.

You might see these problems if your motor overheats:

- Winding insulation breaks down, leading to short circuits.

- Bearings wear out faster.

- The motor loses power or stops working.

About half of all electric motor failures happen because of overheating. Common causes include running the motor with too much load, poor cooling, or high room temperatures. Using temperature sensors helps you spot problems early. Always keep your motor within the temperature limits set by the manufacturer.

Note: If you notice your motor feels hot to the touch or smells like burning, stop and let it cool down. This simple step can save you from bigger repairs later.

Environmental Factors

The environment around your motor plays a big role in how long it lasts. Dust, sand, and other tiny particles can get inside and wear down the bearings and insulation. Chemicals and saltwater cause corrosion, which eats away at metal parts. Extreme heat or cold can make materials brittle or cause insulation to fail. High pressure can even bend the motor housing and put extra stress on the bearings.

Here are some common environmental threats:

- Abrasive dust and sand

- Corrosive chemicals or saltwater

- Very high or low temperatures

- High-pressure environments

If you use brushless motors in harsh places, you need to check them more often. Cleaning and protecting your motor from dirt and moisture will help it last longer.

Improper Use

How you use your motor affects its lifespan. Overloading the motor, running it at speeds higher than recommended, or using it for tasks it was not designed for can all cause early wear. If you ignore regular maintenance or use the wrong type of lubricant, you risk damaging the bearings and other parts.

You can avoid many problems by following the manufacturer’s guidelines. Make sure you do not push the motor past its limits. Regular checks and proper care keep your motor running smoothly for years.

Brushless Motors Lifespan

Typical Service Life

You can expect brushless motors to last much longer than brushed motors. Most leading manufacturers report that these motors often run for over 20,000 hours when you use them within the recommended limits. In many cases, you will see service lives that reach tens of thousands or even hundreds of thousands of hours, especially with proper care and maintenance. Industrial-grade models usually last longer than consumer-grade ones because they use stronger materials and better cooling systems.

Here is a quick overview of typical service life:

| Motor Type | Typical Lifespan (Hours) | Typical Lifespan (Years, Normal Use) |

|---|---|---|

| Brushed DC Motor | 2,000 – 5,000 | 1 – 3 |

| Brushless DC Motor | 20,000+ | 10+ |

| Industrial Brushless Motor | 50,000+ | 15+ |

🕒 Tip: If you use your motor in a clean, cool environment and follow the manufacturer’s guidelines, you can expect it to last for many years.

Factors Affecting Longevity

The actual lifespan of your motor depends on several important factors. You have control over many of these, so you can help your motor last longer.

- Bearing Quality: Bearings are the main parts that wear out. High-quality bearings can last up to 50,000 hours or more. If you choose motors with certified bearings and keep them well-lubricated, you will see better results.

- Operating Conditions: Motors that run in dusty, wet, or hot environments wear out faster. Clean, dry, and cool spaces help your motor last longer.

- Maintenance: Regular maintenance makes a big difference. Studies show that using predictive tools like vibration monitoring can reduce maintenance costs by 25% and cut accident rates by 75%. If you check your motor often and fix small problems early, you avoid bigger failures later.

- Usage Patterns: Motors that run at full load all the time or face frequent starts and stops wear out faster. If you avoid overloading and let your motor cool down when needed, you extend its life.

- Component Quality: Motors built with advanced materials and strong mechanical parts resist wear better. Top brands use these features to boost reliability and service life.

🔍 Note: Without regular care, the risk of failure rises as the motor ages. Predictive maintenance and risk assessment tools help you spot trouble before it leads to breakdowns.

Signs of Wear

You can spot early warning signs if you pay attention to how your motor sounds and feels. Field technicians look for these common symptoms:

- Unusual noises like grinding, buzzing, squealing, or banging. These often mean the bearings are worn or parts are loose.

- Excessive vibration or shaking. This can signal misalignment, imbalance, or failing bearings.

- Overheating beyond normal levels. If your motor feels hot or smells like burning, you may have a cooling or overload problem.

- Reduced performance or power output. Worn windings or internal faults can cause your motor to slow down or lose strength.

- Electrical issues such as erratic behavior or tripped breakers. These may point to winding problems or supply faults.

You can use special diagnostic tools to catch problems early. Vibration analysis helps you find bearing issues or misalignment. Thermography uses infrared to spot hot spots that show airflow or electrical problems. Motor Circuit Analysis™ checks for winding faults before they cause a breakdown. Regular checks with these tools help you avoid sudden failures and keep your motor running smoothly.

⚠️ Alert: If you notice any of these signs, stop the motor and inspect it right away. Early action can save you from costly repairs or replacements.

Maintenance Tips

Regular Checks

You should inspect your motor on a regular schedule. Industry standards suggest checking every 3 to 6 months. This interval helps you catch problems before they become serious. During each inspection, look for signs of wear, listen for unusual noises, and check for excess vibration. Use simple tools like thermography to spot hot spots and vibration analysis to detect misalignment. For critical motors, collect baseline data and monitor changes over time. This risk-based approach helps you focus on the most important equipment.

🛠️ Tip: Regular checks prevent unexpected breakdowns and keep your motor running smoothly.

Cleaning and Protection

Keeping your motor clean protects it from dust, dirt, and moisture. Start by wiping the exterior with a soft brush or dry cloth. Remove any debris around the motor to allow proper cooling. In wet or humid environments, use sealed enclosures to keep moisture out. Inspect wiring and connectors for looseness or corrosion. Always disconnect power and wear protective gear before cleaning.

- Clean the motor surface and cooling fins regularly.

- Make sure nothing blocks airflow or heat dissipation.

- Protect the motor from water and chemicals with proper covers.

- Check connectors and wires for damage or oxidation.

These steps help your motor last longer and perform better.

When to Replace Bearings

Bearings are the main parts that wear out in your motor. You should replace them if you hear grinding noises, feel extra vibration, or notice overheating. Manufacturers recommend condition-based replacement, which means you change bearings when you detect early signs of failure. For heavily used motors, plan bearing replacement during scheduled shutdowns. Always follow the manufacturer’s guidelines for lubrication and installation. Retek Motion advises using high-quality bearings and monitoring their condition with vibration analysis.

| Maintenance Task | Best Practice (Retek Motion) |

|---|---|

| Bearing Lubrication | Use correct lubricant, avoid overgreasing |

| Bearing Replacement | Replace based on condition or risk schedule |

| Condition Monitoring | Use vibration analysis and regular checks |

⚠️ Alert: Never ignore early warning signs from your bearings. Quick action prevents bigger problems and costly repairs.

You can count on these motors for long-lasting, reliable performance when you follow a good maintenance routine. Regular checks and cleaning help prevent early wear. The table below shows why these motors stand out for reliability:

| Feature | Brushed Motors | Brushless Motors |

|---|---|---|

| Operating Life | 1,000 to 8,000 hours | 10,000 to 100,000 hours |

| Maintenance | Frequent | Minimal |

| Reliability | Lower | Higher |

| Electrical Noise | Higher | Lower |

- Stick to maintenance schedules.

- Monitor for signs of wear.

- Use expert tips from Retek Motion for the best results.