Imagine choosing a power tool at the store and wondering if it uses a brushed or brushless motor. Not all small equipment uses motors brushless because cost, complexity, and application needs shape this decision. For example, brushed motors often power linear actuators, power tools, and medical equipment, while brushless motors appear in high-speed cooling fans, drones, and computer hardware.

- Brushed motor applications:

- Power tools

- Robotics

- Consumer appliances

- Brushless motor applications:

- Drones

- Computer hardware

Each type serves a purpose, and the right choice depends on the situation.

Key Takeaways

- Brushed motors cost less, are simple to use, and easy to repair, making them ideal for budget-friendly and rugged small equipment.

- Brushless motors run more efficiently, last longer, and need less maintenance but come with higher upfront costs and more complex electronics.

- Choosing the right motor depends on your equipment’s needs, including power source, speed, lifespan, and environment.

- Brushless motors save money over time by reducing energy use and repair costs, especially for frequent or demanding use.

- Working with experts like Retek Motion helps you find a motor that fits your project perfectly, balancing cost, performance, and durability.

Motor Types

Small equipment relies on several types of motors. The most common include DC motors, stepper motors, servomotors, and motors brushless. Each type offers unique features that suit different applications.

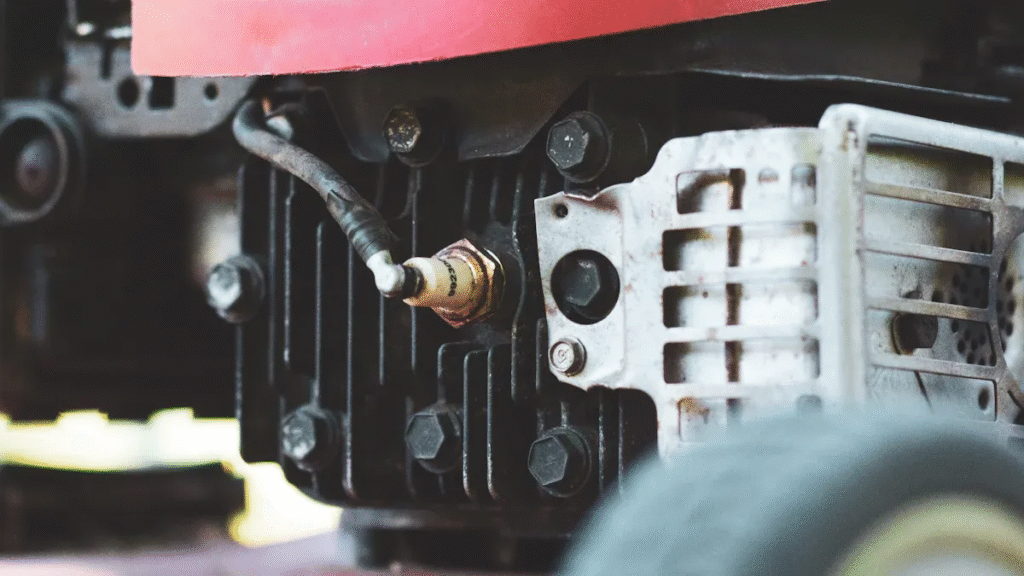

Brushed Motors

Brushed motors use a simple design with brushes and a commutator to deliver power to the rotor. This design allows for a compact size and high power density. Many brushed motors feature an ironless rotor, which gives them a low moment of inertia and fast reaction time. These motors provide a linear torque-speed relationship, making them easy to control. They also offer high acceleration and peak torque without risk of demagnetization. Brushed motors operate efficiently due to low friction and good thermal dissipation. Their robust construction resists shocks and vibration, making them ideal for portable tools and small devices. Maintenance involves replacing brushes, but the process remains straightforward.

Tip: Brushed motors often suit applications where cost, simplicity, and ruggedness matter most.

Motors Brushless

Motors brushless, also known as BLDC motors, use electronic commutation instead of brushes. This design eliminates mechanical wear from brushes, resulting in longer lifespan and less maintenance. Motors brushless operate with higher efficiency, often reaching 85-90%. They generate less heat and electromagnetic interference. These motors come in subtypes such as outrunner and inrunner, and they fit a range of voltage classes and power ratings. Motors brushless excel in applications that demand accuracy, durability, and long-term reliability, such as drones and computer hardware.

| Category | Types/Subtypes |

|---|---|

| Motor Types | Brushless Motors (BLDC, BLAC), DC Motors, Stepper Motors, Servomotors |

| Brushless Motor Subtypes | Outrunner Motors, Inrunner Motors |

| Rotor Types | Permanent Magnet, Electronically Commutated |

| Voltage Classes | Low Voltage (up to 12V), Medium Voltage (12V-48V), High Voltage (above 48V) |

| Power Ratings | Low Power (up to 50W), Medium Power (50W-500W), High Power (above 500W) |

Key Differences

Brushed and brushless motors differ in several key areas. Brushed motors achieve about 75-80% efficiency due to friction and heat loss from the brushes. Motors brushless reach higher efficiency, around 85-90%, because they avoid this friction. Lifespan also varies. Brushed motors last between 1,000 and 8,000 hours, while motors brushless can operate for 10,000 to 100,000 hours. Maintenance needs set them apart as well. Brushed motors require regular brush replacement, causing downtime. Motors brushless need less maintenance, usually only for bearings.

| Performance Aspect | Brushed Motor | Brushless Motor |

|---|---|---|

| Efficiency | 75-80% | 85-90% |

| Lifespan (hours) | 1,000-8,000 | 10,000-100,000 |

| Maintenance | Regular brush replacement | Mainly bearing maintenance |

Barriers to Motors Brushless

Cost Factors

Motors brushless often cost more than brushed motors. The higher price comes from advanced materials and the need for electronic controllers. For small equipment, this upfront cost can be 20-25% higher than traditional motors. Many small and medium enterprises choose brushed motors because they want to keep expenses low. The supply chain for motors brushless also depends on rare-earth materials like neodymium and dysprosium. These materials come mostly from a few countries, which can cause price swings and supply risks. Manufacturers must also spend more on research and development to meet changing regulations. These factors make motors brushless less attractive for cost-sensitive applications.

Note: Brushed motors remain the more cost-effective option for devices with a short expected lifespan.

Key cost barriers:

- High initial purchase price

- Dependence on rare-earth materials

- Increased R&D and compliance costs

- Price volatility in the supply chain

Complexity and Electronics

Motors brushless need more advanced electronics than brushed motors. Each motor requires an electronic controller to manage the flow of electricity. This controller uses semiconductor switches, such as transistors, to send current to the right coils at the right time. The system must also detect the rotor’s position, often using Hall effect sensors, rotary encoders, or sensorless methods. These extra components add complexity to the design and assembly process.

| Component | Purpose |

|---|---|

| Electronic Controller | Replaces mechanical commutator |

| Semiconductor Switches | Direct current to motor windings |

| Position Sensors | Detect rotor position for timing |

| Microcontroller (optional) | Advanced control and efficiency management |

Modern integrated circuits and microcontrollers have made these systems easier to design and cheaper to produce. However, the added electronics can still be a point of failure. In harsh environments, dust, moisture, or vibration can damage sensitive components. Brushed motors, with their simple construction, often survive better in tough conditions.

- Motors brushless cannot run without their control electronics.

- Advanced electronics require skilled installation and troubleshooting.

- The complexity increases the risk of malfunction and repair difficulty.

Maintenance and Repair

Brushed motors need regular maintenance because the brushes and commutator wear down over time. Users must replace brushes and sometimes the entire motor. Motors brushless do not have brushes or commutators, so they avoid this kind of mechanical wear. This means less frequent maintenance and longer service life.

However, when motors brushless fail, the problem often lies in the electronic controller. Repairing or replacing these electronics can be more difficult and expensive than swapping out brushes. In remote or less technically skilled areas, finding the right parts or expertise can be a challenge. In harsh environments, the electronics in motors brushless may fail before the motor itself, while brushed motors can keep running with simple repairs.

- Brushed motors: Require periodic brush and commutator replacement.

- Motors brushless: Lower mechanical maintenance, but higher risk of electronic failure.

- Electronics in motors brushless can be vulnerable in tough conditions.

Pros and Cons

Brushed Motor Pros and Cons

Brushed motors offer several advantages for small equipment, but they also come with notable drawbacks.

| Advantages of Brushed Motors | Disadvantages of Brushed Motors |

|---|---|

| Cost-effective: inexpensive to produce and purchase, suitable for budget-sensitive applications. | Maintenance required: brushes and commutator wear out, needing regular replacement and cleaning. |

| Simple and reliable construction, easy to manufacture and repair. | Reduced efficiency and lifespan due to friction and heat generated by brush-commutator contact. |

| Ease of control: direct physical connection allows precise speed and torque regulation. | Environmental impact: carbon dust from brush wear contaminates the environment. |

| Suitable for applications where initial cost and straightforward speed control are priorities. | Shorter lifespan in high-intensity applications compared to brushless motors. |

Regular inspection and replacement of brushes keep brushed motors running, but this increases downtime and operational costs. Friction from the brushes generates heat and electrical noise, which can limit performance and reduce lifespan, especially at high speeds.

Brushless Motor Pros and Cons

Motors brushless bring a different set of strengths and weaknesses to small equipment.

- High efficiency and longer operational life due to the absence of brushes.

- Lower maintenance needs, as there are no brushes or commutators to replace.

- Reduced heat generation and less electrical noise, which improves reliability.

- Precise electronic control allows for better power delivery and torque management.

- Higher initial cost and greater complexity because of the need for electronic controllers.

- Repairs can be more difficult and expensive, especially if the control electronics fail.

- Sensitive electronics may not perform well in harsh environments with dust or moisture.

Motors brushless often suit professional or industrial equipment where efficiency, durability, and long-term reliability matter most.

Efficiency and Durability

Efficiency measures how well a motor converts electrical energy into mechanical power. Brushless motors achieve efficiency rates of 85-90%, while brushed motors typically reach 75-80%. The absence of brushes in brushless motors eliminates friction losses, which reduces heat and extends operational life. This higher efficiency means devices like drones and power tools can run longer on a single battery charge.

Brushed motors lose more energy as heat because of friction between the brushes and commutator. This not only lowers efficiency but also shortens the motor’s lifespan. Proper maintenance, such as cleaning and lubricating, can extend the life of a brushed motor, but it cannot match the durability of a brushless design. For demanding applications, brushless motors provide better energy utilization and require less frequent repairs.

Choosing the Right Motor

Application Needs

Selecting the right motor for small equipment depends on several important factors. Each application has unique requirements that influence the best choice.

- Power source: AC motors work well with wall outlets, while DC motors suit battery-powered devices.

- Speed settings: Some equipment needs variable speeds, while others operate at a fixed rate.

- Operating lifetime: Brushless DC and stepper motors last longer and need less maintenance than brushed DC motors.

- Duty cycle: Motors must match the expected run time to avoid overheating.

- Enclosure and protection: Motors may need protection from moisture, dust, or heat.

- Voltage compatibility: The motor’s voltage must match the available power supply.

- Performance temperatures: Motors should handle the expected ambient temperature.

- Control capabilities: Some applications require forward and reverse rotation.

- Capacity and size: The motor must fit the load and installation space.

- Noise levels: Low-noise motors are important in quiet environments.

- Maintenance: Easy maintenance and available expertise help reduce downtime.

- Feedback components: Sensors or encoders can monitor performance.

- Operating costs: Consider initial price, maintenance, and lifespan for overall value.

A careful review of these factors ensures the motor will meet the equipment’s needs and perform reliably.

Budget Considerations

Budget plays a major role in motor selection. Brushed motors cost less to buy and install, making them a good choice for light or occasional use. Their simple design keeps upfront expenses low, which appeals to projects with tight budgets or short-term needs. However, brushed motors require regular maintenance and have a shorter lifespan. Over time, these costs add up.

Brushless motors cost more at first but save money in the long run. They need less maintenance and use energy more efficiently. For equipment used often or in demanding settings, brushless motors can lower total ownership costs. For example, over three years, a brushless motor can save about $330 compared to a brushed motor, thanks to reduced repairs and energy use.

| Cost Aspect | Brushed Motor | Brushless Motor |

|---|---|---|

| Initial Cost | Lower | 30-50% higher |

| Maintenance | Recurring | Minimal |

| Energy Use | Higher | Lower |

| 3-Year Total Cost | $930 | $600 |

Retek Motion Solutions

Retek Motion helps customers choose the best motor for their needs by offering fully customized solutions. Their team works closely with clients to design motors that match exact requirements, rather than selling standard models. Retek’s services include professional design support, advanced manufacturing, and strict quality control. They also provide flexible packaging and shipping options. For specialized applications, such as personal care devices, lawn mowers, or EC fan motors, Retek delivers tailored products with advanced features. This approach ensures each customer receives a motor that fits their equipment and performance goals.

Retek Motion’s expertise and collaborative process make it easier for customers to select and develop the right motor for any small equipment project.

Many small equipment manufacturers still choose brushed motors because of lower cost, simple design, and easy repairs. Brushless motors gain popularity in mid-power applications like pumps and medical devices, driven by efficiency and smart features. Users should compare their needs, expected lifespan, and budget before deciding. For more details or expert advice, Retek Motion offers support:

| Contact Person | Phone/WhatsApp | |

|---|---|---|

| Sean Zheng | sean@retekmotion.com | +86-13013797383 |

Explore available resources to learn more about motor types and find the best fit for your project.