When you make or improve a drone, you want it to work well and last long. Brushless DC motors are the top choice for drones. They are very efficient, strong, and light for their power. A servo motor is used in robots or RC cars, but brushless DC motors are better for drones. They give more torque and last longer because they do not have brushes that wear out.

- These motors let you control speed exactly and save battery power.

- New sensorless types cost less and are more reliable.

Picking the right motor helps your drone fly longer and break down less often.

Key Takeaways

- Brushless DC motors are best for drones. They work well, are strong, and are light. They last a long time and do not need much care.

- Servo motors are not good for drone propellers. They only turn partway and make the drone heavier. They also use more power.

- Pick the right motor size and KV rating for your drone. This depends on your drone’s frame and propeller size. It helps your drone fly safely and well.

- Match your motor with the right speed controller, battery, and propeller. This makes the drone fly smoothly and helps the battery last longer.

- Buying a brushless motor saves money over time. It needs fewer repairs and lets your drone fly longer. It is also quieter and stronger.

Servo Motor in Drones

Why Not Use a Servo Motor?

A servo motor lets you control movement very exactly. People use it a lot in robots and remote-control cars. In these things, a servo motor can:

- Give information about where it is and how fast it moves with sensors like encoders or potentiometers.

- Stay in one spot or speed until you tell it to change.

- Move robot arms, grippers, and wheels very carefully.

- Steer and move parts in RC cars and planes.

- Turn electric signals into exact turning or straight movement.

You might ask why you cannot use a servo motor to spin your drone’s propellers. The main problem is that a servo motor has limits that make it bad for this job. Most servo motors can only turn about halfway around. Drone propellers need to spin all the way around, not just back and forth. If you try to use a servo motor, the propeller will not keep spinning.

A servo motor also makes your drone heavier. This extra weight means your drone cannot fly as long or carry as much. Because a servo motor always needs to adjust, it uses more power and drains your battery faster. You also need more control parts to use a servo motor, which makes building your drone harder. Good servo motors cost more than other choices, and they might not work well in bad weather. For all these reasons, you should not use a servo motor to spin your drone’s propellers.

Tip: Use a servo motor for jobs that need careful movement, like camera gimbals or landing gear, but not for spinning propellers.

Servo Motor Alternatives

There are better motors for making drones fly. The most common choices are brushless DC motors, brushed DC motors, stepper motors, and continuous rotation servos. Each kind has good and bad points.

| Motor Type | Motion Range | Control Method | Typical Drone Application |

|---|---|---|---|

| Traditional Servo Motor | Limited angular range (~180°) | Closed-loop with positional feedback | Precise angular positioning for control surfaces or gimbals |

| Continuous Rotation Servo | Unlimited rotation in either direction | Closed-loop, speed and direction control | Continuous rotational motion for propulsion or continuous actuation |

| Stepper Motor | Discrete steps, incremental motion | Open-loop, no feedback | Less common; used where cost and simplicity are prioritized over speed and torque |

Brushless DC motors are the best for making drones fly. They work well, last a long time, and do not need much care. Brushed DC motors cost less and are easy to swap, but they break faster and are louder. Stepper motors move in tiny steps and do not need feedback, but they are not fast or strong enough for most drones. Continuous rotation servos can spin all the way around, but they are not as strong or efficient as brushless motors.

Pick the motor that matches your drone’s size, weight, and what you want it to do. For most drones, a brushless DC motor works best. Only use a servo motor for drone parts that need careful, small movements.

Best Motor Type

Brushless DC Motor

If you want your drone to work well and last, you need a good motor. A brushless DC motor is the best choice for drones. This motor has coils that stay still and magnets that spin. There are no brushes inside, so there is less rubbing and almost nothing wears out.

Key features of brushless DC motors include:

- They use less battery and make your drone react fast.

- Your drone can fly faster and do harder jobs.

- The motor is quiet, so your drone does not make much noise.

- It is light, so your drone can move easily and stay in the air longer.

- It uses electronics instead of brushes, so you do not have to fix it much.

- The motor lasts a long time because only the bearings wear out.

Note: A brushless DC motor needs an electronic speed controller, or ESC. The ESC sends power to the coils at the right time. This keeps the motor running smooth and strong.

You also get better control with things like field-oriented control and sensors. These help you control speed and torque very well. This is important for steady flight and sharp turns. The design helps the motor stay cool and gives it more power for its weight. Your drone can carry more and fly farther.

Why Brushless Is Preferred

You may wonder why people pick brushless motors over brushed or stepper motors. The main reasons are better performance, more trust, and saving money over time.

| Feature | Brushed Motors | Brushless Motors | Best Use Cases |

|---|---|---|---|

| Cost | Cheaper at first, good for simple things | Costs more at first because of better parts | Toys, cheap drones, and small devices |

| Efficiency | Not as good because of brush friction | Very good, so less energy is wasted | Fast drones, electric cars, robots |

| Maintenance | Needs fixing often because brushes wear out | Needs little fixing; lasts longer | Things that need to work well all the time |

| Torque | Okay for easy jobs, not very strong | Stronger, good for hard work | Lifting, racing drones, big jobs |

| Noise | Makes more noise because of brushes | Quieter, good if you want less sound | Places where you need it quiet |

Brushless motors do not have brushes, so there is less rubbing and breaking. You do not have to fix them as much, so you can fly more. They use energy better, so your drone flies longer on one battery. They are also quiet, so you do not bother people or animals.

A brushless motor lasts much longer than a brushed one. Brushed motors may only work for 1,000 to 3,000 hours. With care, a brushless motor can last over 5,000 hours. Most of the wear comes from the bearings, not the motor. This makes brushless motors great for drones that take pictures, help on farms, or check things, because you need them to work well.

You pay more at first for a brushless motor, but you save money later. You do not have to buy new motors often, and you use less battery. For drones, every bit of weight and flight time matters, so this is a good deal.

Tip: If you want your drone to last, fly far, and carry more, always pick a brushless DC motor.

New ideas in drone motors make brushless motors even better. Makers use lighter parts, smarter electronics, and better cooling. Some motors, like the T-Motor U12II, give more power and keep out dust and water. New types, like coreless motors and permanent magnet synchronous motors, make drones even more efficient and easy to control. These changes help your drone fly longer, lift more, and work in tough places.

Other Motor Options

Stepper Motors

You can find stepper motors in 3D printers and CNC machines. These motors move in tiny, exact steps. They let you set their position very accurately without feedback sensors. But stepper motors have some problems for drones. They give strong torque when moving slow. When they spin faster, the torque drops a lot. Drones need motors that keep strong torque at high speeds to fly well.

| Characteristic | Description |

|---|---|

| Torque Profile | High at low speed, drops at high speed |

| Positioning Accuracy | Very precise, stops exactly where you want |

| Control Type | Open-loop, simple to control |

| Holding Torque | Can hold position without using much power |

| Limitations | Not good for high-speed, high-power jobs like drone flight |

Stepper motors always use the same amount of current. This makes them less efficient and hotter than brushless motors. You might have trouble with resonance and stalling if you use them for drone propellers. Because of these reasons, stepper motors are better for slow, careful jobs, not for flying drones.

Brushed DC Motors

Brushed DC motors are easy to use and cost less. You see them in toy drones and small devices. They have brushes inside that switch the current and spin the shaft. The brushes wear out after a while, so you must fix or replace the motor often. Brushed motors are louder and do not last as long as brushless motors.

| Aspect | Brushed DC Motors | Brushless DC Motors |

|---|---|---|

| Efficiency | Lower | Higher |

| Lifespan | Shorter (brush wear) | Longer (fewer wearing parts) |

| Maintenance | Needs regular care | Almost no maintenance |

| Noise | Louder | Quieter |

| Cost | Lower | Higher |

You can control brushed motors with simple circuits. This makes them good for beginners. But they waste more energy and get hot fast. For bigger drone projects, brushless motors work better and last longer.

Tip: Check your brushed motors for dust and worn parts. Clean them and keep them dry to help them last longer.

Hybrid and Uncommon Alternatives

Some drones use hybrid or rare types of motors. Hybrid drones might use electric motors with fuel cells or small engines. These designs try to give longer flight times and more power. Some test drones use methanol range extenders or superconducting motors. Fixed-wing hybrid drones mix airplane wings and rotors for better flying.

You might see these motors in labs or special projects. They are not common in hobby or business drones yet. Hybrid systems can make drones heavier and harder to build or fix. They also affect the environment in different ways. Electric motors are quiet and do not make direct emissions, but making and recycling batteries matters too. Fuel cells and hybrid engines can lower emissions if you use clean energy, but they need extra parts.

If you want to try new things, hybrid motors are interesting. For most people, brushless DC motors are still the best choice for drones today.

Choosing the Right Motor

Size and Weight

You need to match your motor to your drone’s size and weight for safe and efficient flight. Start by checking your drone’s frame size and the propeller size it supports. Use the table below to guide your motor selection:

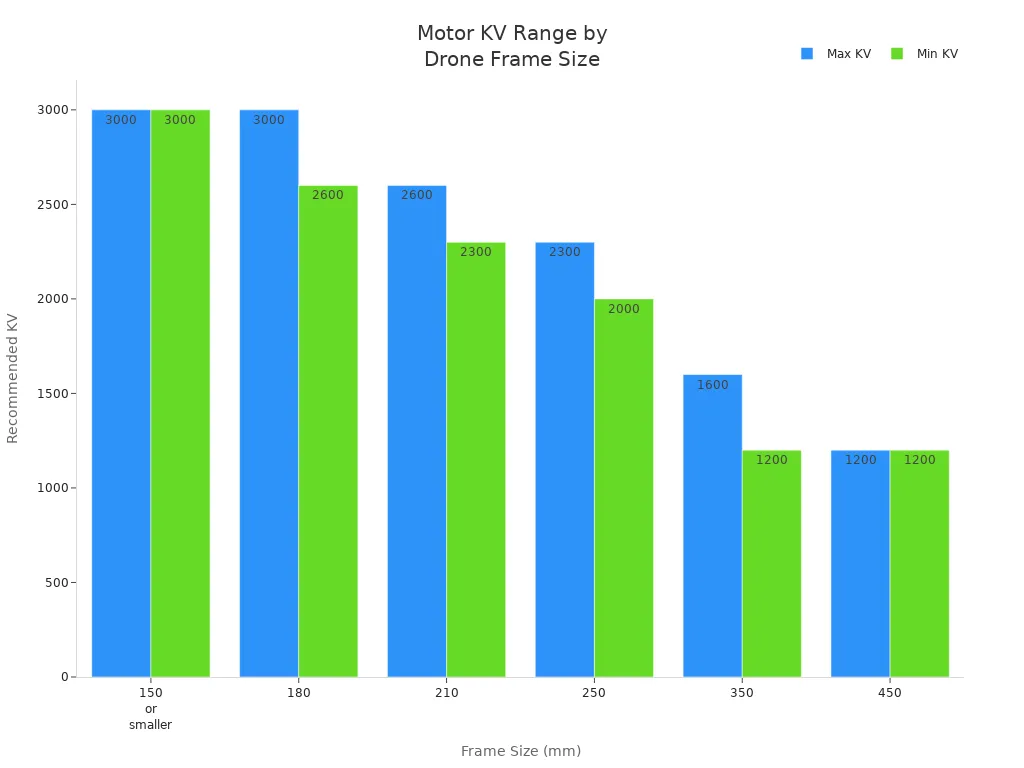

| Frame Size (mm) | Propeller Size (inches) | Recommended Motor Size (Stator Width x Height in mm) | Typical KV Range | Battery Voltage Compatibility |

|---|---|---|---|---|

| 150 or smaller | 3 or smaller | 1105 – 1306 or smaller | 3000 KV and higher | 1S |

| 180 | 4 | 1806, 2204 | 2600 – 3000 KV | 2S – 3S |

| 210 | 5 | 2205 – 2208, 2305 – 2306 | 2300 – 2600 KV | 3S – 4S |

| 250 | 6 | 2206 – 2208, 2306 | 2000 – 2300 KV | 4S – 6S |

| 350 | 7 | 2506 – 2508 | 1200 – 1600 KV | 4S – 6S |

| 450 | 8, 9, 10 or larger | 26XX and larger | 1200 KV and lower | 6S – 10S |

Choose a motor with the right stator size and KV rating for your frame and propeller. Larger drones need bigger motors with lower KV ratings. Smaller drones use lighter motors with higher KV values.

Power and Efficiency

The weight of your drone decides how much power your motors must deliver. Heavier drones need more thrust to lift off and stay in the air. You can use this formula to estimate power needs:

Power (W) = (Thrust (N) × Voltage (V)) / Motor Efficiency (η)

For example, a drone weighing 1.5 kg may need about 296 watts if you use a 14.8V battery and a 90% efficient motor. Higher efficiency means your drone flies longer and uses less battery. Efficient motors waste less energy as heat and keep your battery healthy.

- Efficient motors give you more thrust per watt.

- Less heat means longer flight times.

- Proper tuning and matching with propellers help you get the best results.

Tip: Always check your thrust-to-weight ratio. For stable photography, aim for a ratio of 3:1 to 4:1. For racing, go above 10:1 for fast moves.

Matching to Drone Design

You must match your motor to your drone’s design and electronics. Make sure your motor, ESC, battery, and propeller all work together.

- Match ESC voltage and current ratings with your motor and battery.

- Use ESC firmware that supports your motor type.

- Set motor timing in the ESC for smooth operation.

- Choose propellers that fit your motor’s power and speed.

If you balance all these parts, your drone will fly safely and efficiently. Always test your setup before flying to avoid damage and get the best performance.

Now you know brushless DC motors work best for drones. They give good power, use less energy, and last a long time. Experts say these motors are better than brushed motors or servo motors for flying. If you pick the right motor, propeller, and battery, your drone will fly steady and last longer. Use these ideas to make a drone that does what you want. Believe in your choices and have fun flying as you get better.