T-Motor, EMAX, Rcinpower, and DJI stand out as leading brands in the world of motors for drones. These manufacturers deliver impressive results, with models like the T-Motor F40 Pro 2306-2400 known for high thrust and the EMAX RS2306-2750 balancing power and efficiency. Brushless motors dominate the market due to their reliability, precision, and long lifespan. Choosing the right motor depends on the drone’s purpose, whether for racing, aerial photography, or commercial operations.

The drone motor market continues to grow rapidly, driven by technological advancements and increasing use in diverse applications.

Key Takeaways

- Brushless outrunner motors are the best choice for most drones because they offer high efficiency, long life, and strong performance.

- Choosing the right motor depends on the drone’s size, purpose, and required thrust-to-weight ratio to ensure stable and efficient flight.

- Top brands like T-Motor, EMAX, Rcinpower, and DJI provide reliable motors suited for racing, photography, and heavy-lift drones.

- Always match motor specifications with the drone’s frame, propeller size, ESC, and battery to avoid overheating and ensure smooth operation.

- Use a step-by-step selection process and thorough testing to find the best motor setup, improving flight time, control, and durability.

Motors for Drones

Types of Motors

Motors for drones come in several main types, each designed for specific applications and performance needs:

- Outrunner Brushless Motors: These motors feature a stationary coil inside and rotating magnets outside. This design produces high torque at low RPMs, making them ideal for most consumer and commercial drones. Outrunner brushless motors deliver smooth, efficient performance, which is essential for aerial photography and stable flight.

- Inrunner Brushless Motors: Inrunner motors have the magnets inside and the coils outside. They spin at higher speeds but generate less torque, so they are less common in typical drone builds.

- Brushed Motors: Brushed motors use physical brushes to transfer electricity. They are cost-effective and simple but have shorter lifespans and require more maintenance. Manufacturers often use them in toy drones or low-cost models.

- Specialty Motors: Some drones use coreless motors for lightweight agility, gimbal motors for camera stabilization, or tilt-rotor motors for vertical takeoff and landing.

Outrunner brushless motors remain the preferred choice for most drones due to their high torque, efficiency, and reliability.

Brushless vs Brushed

The debate between brushless and brushed motors for drones centers on efficiency, durability, and performance. Brushless motors dominate the market for several reasons:

- Brushless motors offer higher efficiency and longer lifespan, often exceeding 20,000 hours, while brushed motors typically last up to 1,000 hours.

- The absence of brushes in brushless motors reduces friction, heat, and maintenance needs. This design also allows for quieter operation and better thermal management.

- Brushless motors support a wider range of voltages and power outputs, making them suitable for everything from micro drones to heavy-lift commercial models.

- Brushed motors, while cheaper, generate more heat, require frequent maintenance, and are less reliable for demanding or long-duration flights.

| Feature | Brushed DC Motors | Brushless DC Motors (BLDC) |

|---|---|---|

| Lifespan | Up to ~1,000 hours | Often exceeds 20,000 hours |

| Maintenance | High (brush replacement needed) | Low (minimal maintenance) |

| Efficiency | Lower, more heat generated | Higher, less energy wasted as heat |

| Application | Toys, low-cost drones | Most modern consumer and commercial drones |

Motors for drones must balance torque, speed, and efficiency. Brushless outrunner motors consistently outperform other types, making them the industry standard for reliable and high-performance drone operation.

Key Selection Criteria

Efficiency

Efficiency stands as a primary factor when selecting motors for drones. Brushless motors achieve efficiency levels between 80% and 95%, far surpassing brushed motors. This high efficiency means more electrical energy converts into mechanical power, resulting in longer flight times and less heat. The motor constant (Km) helps evaluate efficiency by comparing torque output to heat loss. A higher Km indicates better performance with less wasted energy. Engineers often use power analyzers to measure voltage, current, thrust, and RPM under real-world conditions. This approach ensures the chosen motor delivers optimal results for the specific drone setup.

| Motor Type | Typical Efficiency Range |

|---|---|

| DC Motors | 50-80% |

| AC Motors | 75-90% |

| Brushless DC (BLDC) Motors | 80-95% |

Tip: Matching the right motor and propeller combination through testing can maximize efficiency and extend battery life.

Thrust-to-Weight Ratio

The thrust-to-weight ratio determines how well a drone can lift its payload and maneuver. For aerial photography and videography, a ratio of 3:1 to 4:1 offers precise control and supports heavier cameras or batteries. Racing drones often require higher ratios, such as 5:1, for rapid acceleration. For example, a quadcopter weighing 700 grams needs a total thrust of 2,100 to 2,800 grams for stable flight and payload capacity. This balance ensures the drone remains agile without sacrificing stability.

Compatibility

Compatibility between motors, ESCs, and the drone platform is essential for safe and efficient operation. ESCs must match the motor’s voltage and current requirements. Features like field-oriented control (FOC) and programmable ESCs improve torque and speed control. Manufacturers design ESCs and motors to work together, supporting a range of battery voltages and propeller sizes. Selecting compatible components ensures smooth flight and reliable performance.

- ESCs should support the motor’s current draw and voltage.

- Motors must fit the drone’s frame and intended propeller size.

- Programmable ESCs allow fine-tuning for different flight styles.

Durability

Durability depends on both design and materials. Outrunner motors for drones retain about 92% operational status after repeated impacts, outperforming inrunner designs. High-quality bearings and advanced N52H neodymium magnets increase robustness and lifespan. Open motor designs also help with cooling, reducing wear from heat buildup. These features ensure the motor withstands frequent use and occasional crashes, making them ideal for demanding applications.

Choosing Motors

By Drone Size

Selecting the right motor size depends on the drone’s frame and intended performance. Engineers consider several technical parameters, including motor size, KV rating, propeller size, battery cell count, and drone weight. These factors work together to ensure the drone operates efficiently and safely. For example, a small racing drone with a 2-3 inch frame often uses 1103 or 1106 motors, while larger drones with 5-inch props may require 2207 or 2306 motors. Heavy-lift or long-range drones benefit from larger motors like 2806 or 2807, paired with lower KV ratings for greater torque and efficiency.

| Parameter | Description & Influence |

|---|---|

| Motor Size | Ranges from 0702 (Tinywhoops) to 2806 (freestyle/long range) based on drone size and power needs. |

| Motor KV Rating | Higher KV (23000-30000 for Tinywhoops) for speed; lower KV (1200-3000 for larger drones) for torque. |

| Propeller Size | 31-40mm for Tinywhoops; 3-5″ for freestyle/racing; 6-7″ for long range/heavy-lift. |

| Battery Cell Count | 1S for smallest drones; up to 6S for high-performance models. |

| Drone Weight | From ~16g (Tinywhoops) to 400-500g (large freestyle/long range). |

Motor performance parameters such as no-load current, maximum current, and thrust-to-power ratio also play a critical role. Matching these specifications with the drone’s propeller size and weight ensures optimal flight and battery life.

By Use Case

The intended use of the drone determines the best motor choice. Racing drones require high KV motors and lightweight frames for speed and agility. Photography and commercial drones need motors that deliver stable thrust and reliability, supporting heavier payloads like cameras. Heavy-lift drones use large, low KV motors to maximize torque and efficiency for industrial tasks.

| Use Case | Motor Model | Key Performance Metrics | Typical Application Details |

|---|---|---|---|

| Racing | Lumenier 2207-7 1750 KV | High KV, lightweight, powerful stator | Speed, agility, aggressive flying |

| Photography | T-MOTOR U15 II KV80 | Max thrust 79 lbs, stability | Aerial photography, industrial use |

| Heavy-lift | MAD M30 100 KV | Max thrust 55 lbs, heavy-duty | Industrial, agricultural drones |

| Commercial | DJI Mavic Air 2, Matrice 300 RTK | Optimized for reliability and endurance | Consumer and commercial drone market |

Motors for drones must align with both the drone’s size and its mission profile. Careful selection ensures safe operation, efficient power use, and the best possible performance for every application.

Recommended Motors

Top Brands

Selecting the right brand ensures reliability and performance for any drone build. Several manufacturers have earned strong reputations for quality and innovation in motors for drones

Many users have shared their experiences with these brands. Some noticed motor warnings in windy conditions, which suggests that environmental factors can affect performance. Others compared the noise levels of DJI motors to the Mavic Mini, highlighting improvements in design and user comfort.

Popular Models

The drone community often recommends specific motor models for their proven performance in real-world scenarios. Each model suits a particular drone size or use case, from racing to heavy-lift applications.

| Model Name | KV Rating | Size/Class | Best For | Key Features |

|---|---|---|---|---|

| T-Motor F90 2806.5 1300KV | 1300 | 7-inch | Long-range, heavy-lift | High torque, efficient for large props |

| AOSRC SUPERNOVA 2207 | 1960-2550 | 5-inch FPV | Freestyle, racing | Responsive, lightweight, durable |

| Racestar 2205 | 2300 | 5-inch | Budget builds, beginners | Affordable, easy to install |

| DJI Mavic Air 2 (integrated) | N/A | Proprietary | Photography, commercial | Quiet, reliable, optimized for DJI drones |

| Lumenier 2207-7 1750KV | 1750 | 5-inch racing | High-speed racing | Powerful stator, smooth throttle response |

| MAD M30 100KV | 100 | Large/industrial | Heavy-lift, agriculture | High thrust, robust for industrial use |

| BetaFPV 0702 | 30,000 | Tinywhoop | Micro drones, indoor flying | Lightweight, efficient, strong performance |

DriveCalculator software helps users analyze and compare these motors by simulating different combinations of batteries and propellers. The tool provides instant feedback on current draw, efficiency, static thrust, and propeller speed. Many drone builders rely on this resource to optimize their setups and achieve the best results.

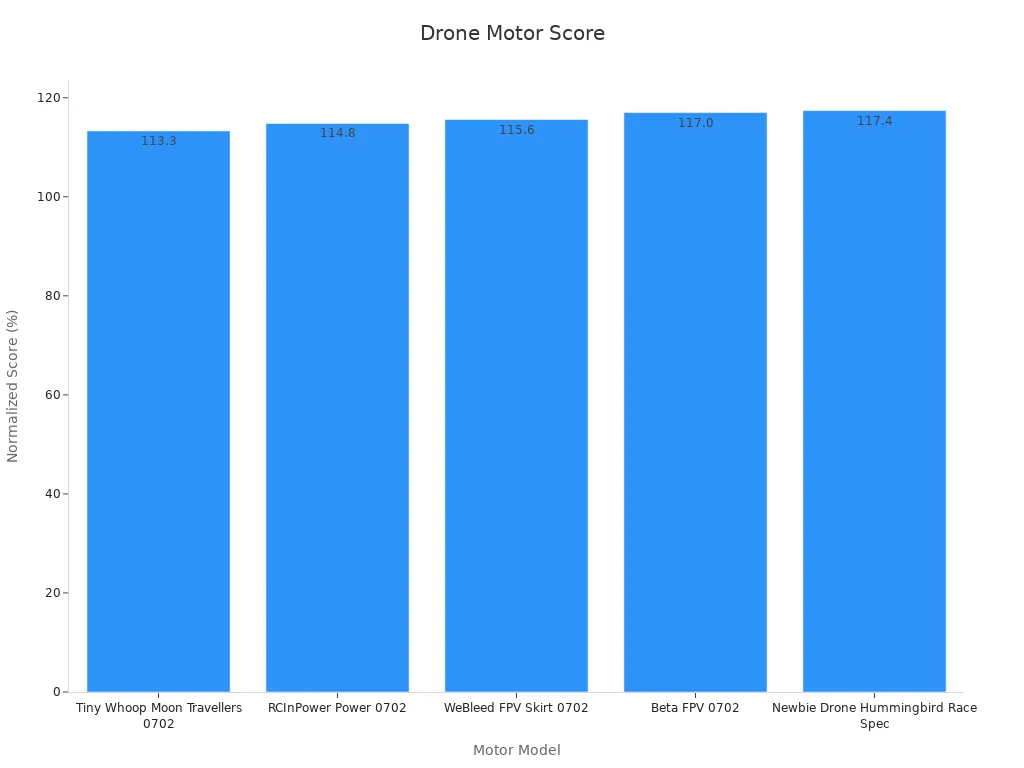

| Motor Model | KV Rating (RPM/V) | Weight (grams) | Key Performance Metrics | Normalized Score (%) |

|---|---|---|---|---|

| Tiny Whoop Moon Travellers 0702 | 32,000 | N/A | High efficiency, balanced weight and performance | 113.3 |

| RCInPower Power 0702 | 29,000 | N/A | Excellent responsiveness and thrust | 114.8 |

| WeBleed FPV Skirt 0702 | 40,000 | N/A | Lightweight, solid performance and efficiency | 115.6 |

| Beta FPV 0702 | 30,000 | Heavier | Strong overall performance | 117.0 |

| Newbie Drone Hummingbird Race Spec | 30,000 | 1.29 | Lightest motor, good responsiveness and efficiency | 117.4 |

These models represent the best choices for their categories. For example, the T-Motor F90 2806.5 1300KV excels in 7-inch long-range drones, providing the torque needed for stable flight and heavy payloads. The AOSRC SUPERNOVA 2207 stands out in 5-inch FPV racing, offering quick response and durability. Racestar 2205 motors appeal to budget-conscious pilots who want reliable performance without a high price tag.

Motors for drones continue to evolve as brands introduce new materials and designs. Real-world feedback and simulation tools help users make informed decisions, ensuring each drone achieves its intended performance.

Selection Guide

Step-by-Step Process

Selecting the right motor for a drone involves a systematic approach. The following steps help ensure the best match for performance and reliability:

- Weigh the complete drone, including all components and payload.

- Determine the frame size and select the appropriate propeller size.

- Choose a target thrust-to-weight ratio. For racing drones, aim for about 5:1. For cinematic or photography drones, a ratio between 3:1 and 4:1 works well.

- Multiply the drone’s weight by the chosen thrust-to-weight ratio to find the total required thrust.

- Divide the total thrust by the number of motors to calculate the minimum thrust per motor.

- Use the table below to match frame size, propeller size, motor size, and KV rating to your drone type:

| Frame Size (mm) | Propeller Size (inch) | Motor Size (mm) | Recommended KV Range | Typical Drone Type |

|---|---|---|---|---|

| ≤150 | ≤3 | 1306 or smaller | ≥3000KV | TinyWhoop, Whoops |

| 210 | 5 | 2204–2206 | 2300–2600KV | Racing, Freestyle |

| 350 | 7 | 2208 | ~1600KV | Long Range |

| 450 | 8–10 | 2212 or larger | ≤1000KV | Heavy Lift, Cinematic |

- Select brushless motors and propellers that can deliver the required thrust per motor.

- Test the chosen setup using a thrust stand to measure actual thrust, temperature, and current draw.

- Adjust motor or propeller choices based on test results to optimize performance and prevent overheating.

Tip: Always match the motor’s voltage and current ratings with the battery and ESC specifications for safe operation.

Checklist

A thorough checklist helps evaluate motor suitability and ensures reliable drone performance:

- Inspect each motor for smooth rotation and absence of bearing play.

- Confirm that motors spin freely without grinding or resistance.

- Listen for unusual sounds during startup and address issues immediately.

- Verify that all motors synchronize properly in multi-rotor systems.

- Check propeller balance and perform vibration analysis to detect early signs of wear.

- Review manufacturer data for efficiency, torque, and temperature management.

- Ensure ESC and battery compatibility with motor current and voltage ratings.

- Conduct real-world testing and adjust components as needed for optimal results.

Note: Consistent testing and careful inspection reduce the risk of in-flight failures and extend the lifespan of drone motors.

Top brands like T-Motor, EMAX, Rcinpower, and DJI lead the market with reliable and efficient drone motors. Efficiency, thrust-to-weight ratio, and compatibility remain critical factors in motor selection. Readers should follow the step-by-step guide and checklist for confident choices. For unique or custom drone builds, consulting manufacturer specifications or expert advice ensures the best results.