You might wonder if you can use drone motors on an electric board. While possible, you will face significant technical challenges. Drone motors often lack the power and torque needed for board applications. Cooling also becomes a concern, as increased power density leads to more heat. For example:

| Aspect | Typical Value or Concern |

|---|---|

| Operating Temp | Keep below 90 °C for safe operation |

| Power Rating | Small EV motors: around 30 kW; drone motors much lower |

| Cooling Challenge | High power density increases parasitic heat and complexity |

You must consider these issues before deciding if this approach fits your DIY project.

Key Takeaways

- Drone motors are lightweight and fast but lack the sustained torque needed for electric boards, making them less suitable for heavy loads or hills.

- Mounting drone motors on boards often requires custom adapters due to size and shaft differences, adding complexity to your build.

- Cooling drone motors is challenging because they generate more heat; proper cooling systems are essential to prevent overheating.

- Using the right ESC and battery designed for electric boards is crucial to avoid failures and ensure safe, reliable performance.

- For most electric boards, motors made specifically for ground vehicles offer better torque, durability, and easier integration.

Drone Motors vs Board Motors

Key Differences

You will notice several important differences between drone motors and board motors. Drone motors focus on lightweight construction and rapid response. Board motors prioritize sustained torque and durability. The design of drone motors enables them to lift payloads efficiently, while board motors must handle the continuous demands of propelling a rider over various terrains.

| Performance Metric | Drone Motors Characteristics | Board Motors Characteristics (Implied) |

|---|---|---|

| Torque-to-Weight Ratio | Maximized to lift payloads efficiently; critical design focus for drones | Lower priority; less emphasis on maximizing this ratio |

| Winding Resistance | Very low to flatten speed-torque curve, enabling stable speed under varying loads | Higher resistance leading to steeper speed-torque curves |

| Speed-Torque Curve | Flatter slope due to low resistance and higher voltage/torque constants; speed remains stable with load changes | Steeper slope; speed drops significantly with increased load |

| Voltage Constant | Higher voltage constant preferred to flatten speed-torque curve, but increases motor size and weight | Typically lower voltage constant |

| Motor Weight | Minimized to improve payload capacity, but trade-offs exist with resistance and size | Generally heavier relative to torque output |

| Control Techniques | Use of field-oriented control (FOC) for precise torque and speed control, enabling rapid changes and stability | Less emphasis on advanced control for rapid torque changes |

You will also find that drone motors often use advanced control methods like field-oriented control (FOC). This technology allows for precise torque and speed adjustments, which is essential for flight stability. Board motors do not require such rapid or complex changes.

Power and Torque

When you compare power and torque, drone motors deliver quick bursts of power to achieve lift and maneuverability. However, they do not sustain high torque over long periods. Board motors, on the other hand, must provide consistent torque to move a rider and overcome resistance from the road. The speed-torque curve for drone motors remains flatter, so speed stays stable even as the load changes. Board motors experience a more significant drop in speed when the load increases. This difference means that drone motors may struggle to maintain performance on an electric board, especially during uphill climbs or when carrying heavier riders.

Cooling Needs

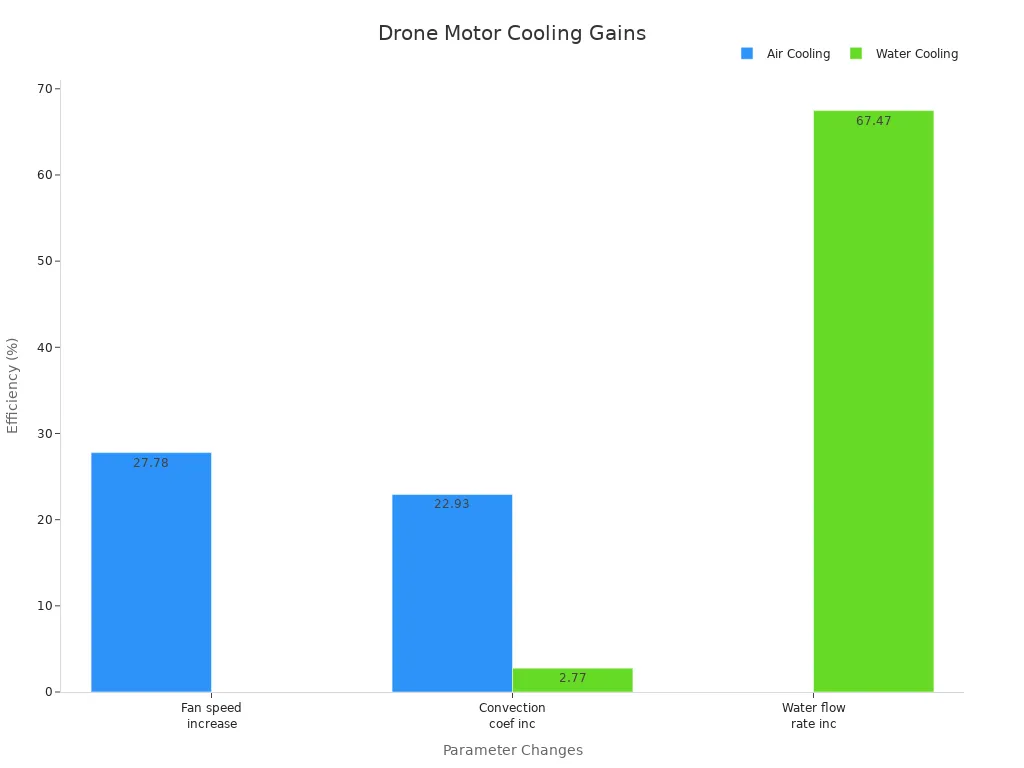

Cooling requirements set drone motors apart from board motors. Drone motors generate significant heat due to their high power density. You will often see water cooling systems used to manage this heat. The following chart shows how cooling efficiency improves with different methods:

Air cooling can increase efficiency by nearly 28% with higher fan speeds, while water cooling can boost efficiency by over 67% with increased flow rates. In contrast, board motors and their batteries rely on lightweight, directional heat dissipation. You will not need the same level of dynamic cooling for a board motor as you would for a drone propulsion system.

Tip: If you plan to use drone motors on an electric board, you must address these cooling challenges to prevent overheating and performance loss.

Motor Compatibility

Size and Mounting

When you compare drone motors to typical electric board motors, you will notice significant differences in physical size, shaft dimensions, and mounting patterns. Drone motors often feature compact designs with lightweight materials, which help reduce overall weight for flight. However, these design choices can create challenges when you try to mount them on an electric board.

| Aspect | Details |

|---|---|

| Mounting Hole Patterns | Some drone motors, such as those using the “Gorilla Mount” pattern, do not match standard 20mm or 30mm mounting holes. You may need custom adapter plates or modified frames to secure them properly. |

| Motor Shaft Materials | Manufacturers use different shaft materials, such as titanium alloy for premium models and steel for budget options. These differences affect durability and mechanical fit. |

| Motor Bell Construction | Construction methods, like one-piece milled aluminum, influence both durability and compatibility with board hardware. |

You may also encounter issues with shaft length and diameter. Board motors typically use longer, thicker shafts to handle higher torque and mechanical stress. Drone motors, designed for propellers, may not provide the same robustness. This mismatch can lead to mechanical failures or require additional modifications.

Note: You should always verify the mounting compatibility before attempting to install a drone motor on your board. Custom brackets or adapters may be necessary, which can add complexity and cost to your project.

ESC and Battery

Electronic Speed Controllers (ESCs) and batteries play a critical role in motor compatibility. Drone motors often pair with ESCs designed for rapid throttle response and lightweight operation. These ESCs may not support the sustained current demands or advanced features needed for electric boards.

You will find that most electric board builders prefer VESCs (Vedder Electronic Speed Controllers). VESCs offer robust current handling, regenerative braking, and customizable firmware. They also provide better thermal management and safety features. Drone ESCs, in contrast, may lack these protections and can overheat or fail under continuous load.

Battery requirements also differ. Drone setups use high-discharge, lightweight batteries optimized for short bursts of power. Electric boards require batteries that deliver sustained current over longer periods. If you use a drone motor with its original ESC and battery, you risk voltage drops, overheating, or even system failure.

NASA’s X-57 technical reports highlight similar integration challenges. The development team faced issues with electromagnetic interference (EMI/EMC), passive cooling, and maintaining high efficiency in motor controllers. They had to redesign and test their systems repeatedly to address these compatibility problems. These lessons show that matching the right ESC and battery to your motor is essential for safe and reliable operation.

Drivetrain Fit

Integrating drone motors into a board drivetrain presents unique challenges. Board motors typically connect to wheels through belts, gears, or direct drive systems. Drone motors, designed for spinning propellers, may not have compatible shaft ends or mounting points for pulleys and gears.

You may need to fabricate custom couplers or adapters to connect the motor shaft to your drivetrain. This process requires precise measurements and machining. Even small misalignments can cause vibration, noise, or premature wear.

Thermal management also becomes a concern. The X-57 Cruise Propulsion System Thermal Analysis emphasizes the importance of adequate cooling airflow and thermal design. Without proper cooling, your drivetrain components and motor can overheat, leading to reduced performance or failure.

Tip: Before starting your build, plan for drivetrain integration. Check shaft compatibility, mounting options, and cooling requirements. Addressing these factors early will save you time and prevent costly mistakes.

NASA’s X-57 project encountered similar issues when integrating different motor types. Their reports document the need for iterative design adjustments, vibration and thermal testing, and strategies to manage electromagnetic interference. These real-world examples underline the complexity of adapting drone motors for board use.

Pros and Cons

Benefits

You gain several advantages when you use drone motors in your electric board project. These motors stand out for their lightweight construction, with models weighing between 163g and 330g. This low weight can help reduce the overall mass of your board, making it easier to carry and potentially improving acceleration. Drone motors also deliver high rotational speeds, with KV ratings from 150 to 380 rpm/V. This feature allows for rapid response and quick acceleration, which some riders may find appealing.

| Feature | Value/Description |

|---|---|

| Weight | 163g – 330g |

| High-Speed (KV) | 150 – 380 rpm/V |

| Voltage Range | 22.2V – 44.4V |

| Max Power Output | Up to 1000W |

| Efficiency | Up to 90% |

You also benefit from precise speed and torque control, thanks to advanced motor controllers. These motors operate quietly and efficiently, sometimes reaching efficiencies above 96%. Their compact size and low vibration design further enhance the riding experience.

Drawbacks

Despite these benefits, you face several limitations when adapting drone motors for electric boards. Most drone motors offer continuous power outputs between 190W and 300W, which may not meet the sustained demands of board riding, especially on inclines or with heavier riders. The shaft and mounting patterns often do not match standard board hardware, requiring custom adapters or modifications.

- You may encounter compatibility issues with ESCs and batteries.

- Drone motors can overheat during prolonged use, as they are designed for short bursts rather than continuous load.

- Mechanical fit and drivetrain integration often require extra work and precision.

A study on drone power plants shows that commercial drone motors have a mean time between failures (MTBF) of about 100,600 hours, but this reliability does not always translate to board use due to different operating conditions.

Safety

You must prioritize safety when experimenting with drone motors on electric boards. These motors can overheat quickly if you push them beyond their intended limits. Inadequate cooling or mismatched ESCs may lead to sudden failures or even fire hazards. Always test your setup in a controlled environment before riding at higher speeds or on public roads.

⚠️ Note: Never exceed the recommended voltage or current ratings for your motor and controller. Use proper fuses and thermal cutoffs to prevent accidents.

You should also inspect all mechanical connections regularly. Loose adapters or misaligned shafts can cause vibration, noise, or catastrophic failure during operation. By following best practices and monitoring your system, you can reduce risks and enjoy a safer DIY experience.

Practical Tips and Alternatives

When to Use Drone Motors

You should only consider using drone motors for an electric board if your project has unique constraints. For example, if you need to minimize weight or experiment with high-speed, low-torque setups, these motors might fit your needs. Advanced mathematical and machine learning models help predict energy consumption and performance by analyzing factors like payload, speed, and battery characteristics. These models show that motor suitability depends on matching the motor’s speed and torque curves to your specific requirements. If your board will carry light loads, travel on flat terrain, and operate at moderate speeds, you may find drone motors adequate. However, for most riders and typical board use, these motors rarely meet the sustained torque and durability demands.

Tip: Always compare the motor’s maximum torque and speed specifications to your board’s requirements before making a decision.

Better Motor Options

For most electric board projects, you will achieve better results with motors designed specifically for ground vehicles. Consider these alternatives:

- Outrunner brushless DC (BLDC) motors: These motors offer high torque and robust construction, making them ideal for electric skateboards and scooters.

- Hub motors: Integrated directly into the wheel, hub motors provide a clean look and reduce drivetrain complexity.

- Geared motors: These motors deliver strong low-end torque, which helps with acceleration and hill climbing.

You can find these motors in a range of sizes and power ratings to match your project’s needs. Manufacturers often provide detailed speed and torque curves, which make it easier to select the right motor for your application.

DIY Advice

If you decide to experiment with unconventional motors, start with a clear understanding of your board’s performance goals. List your required speed, torque, and expected load. Use manufacturer data sheets and performance graphs to compare options. Always test your setup in a controlled environment before riding in public. Monitor temperatures, check for unusual noises, and inspect all mechanical connections regularly.

⚡ Pro Tip: Document your build process and test results. This habit helps you troubleshoot issues and share your findings with the DIY community.

You now see that drone motors rarely meet the demands of electric boards. While you gain lightweight design and quick response, you face low sustained torque, mounting issues, and cooling challenges. Most riders benefit more from motors built for boards.

- Pros: Lightweight, efficient, fast response

- Cons: Low torque, tricky mounting, overheating risk

Always research thoroughly and test safely if you attempt a DIY conversion. Your safety and board performance depend on careful planning.