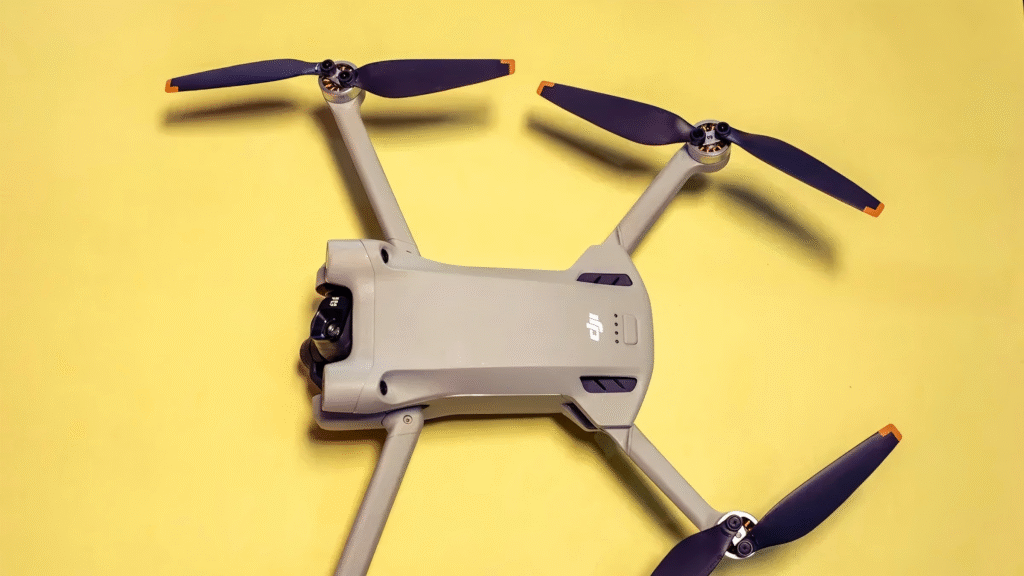

Most drones rely on brushless DC motors for their high efficiency, strong torque, and precise control. Brushed motors and other types still appear in some toy or low-cost models, but brushless designs dominate due to their power-to-weight ratio and reliability. Recent research shows that motor efficiency directly affects energy use and flight performance. Choosing the right motor matters because it impacts thrust, battery life, and overall drone stability. Understanding the differences between Drone Motors helps users select the best option for each application.

Key Takeaways

- Brushless motors are the best choice for most drones because they offer high efficiency, long life, and precise control.

- Brushed motors cost less but wear out faster and need more maintenance, making them better for toy or low-cost drones.

- Choosing the right motor size, KV rating, and propeller helps balance power, flight time, and drone stability.

- Matching motor features to the drone’s purpose, like racing or heavy lifting, improves performance and reliability.

- New motor technologies and smart designs keep drones flying longer and working better in many applications.

Types of Drone Motors

Drone Motors come in several types, each designed for specific applications and performance needs. Understanding these motor types helps users select the right option for their drone, whether for racing, photography, or industrial use.

Brushless Motors

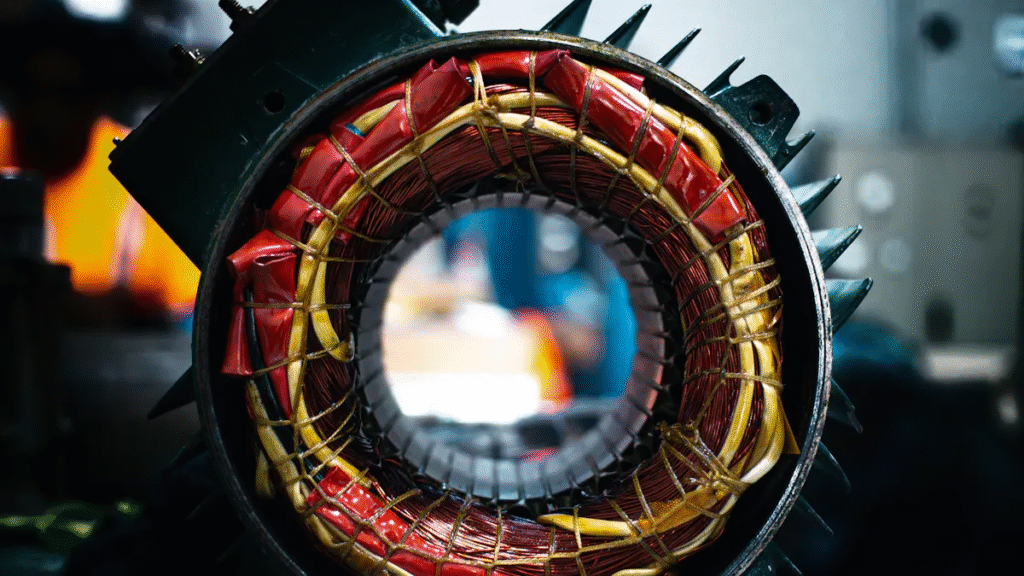

Brushless motors represent the industry standard for most modern drones. Engineers design these motors without brushes, which eliminates the main source of mechanical wear. This design leads to longer service life and reduced maintenance requirements. Brushless motors deliver high efficiency, strong torque, and precise speed control, making them ideal for demanding applications such as FPV racing, aerial photography, and commercial operations.

Note: Brushless motors dominate the drone market due to their superior efficiency and reliability. Technical studies confirm that brushless motors often exceed 80% efficiency, outperforming traditional brushed motors. Advanced testing platforms, such as those from Tyto Robotics, provide precise measurements of thrust and torque, validating the performance advantages of brushless designs in real-world drone applications.

The global market for brushless motors continues to expand rapidly. Key factors driving this growth include increased adoption in commercial, industrial, and military sectors. Military drones, for example, require high reliability and long operational life, which brushless motors provide. The following table highlights market trends and performance benchmarks:

| Region/Segment | Growth/Share | Application/Reason |

|---|---|---|

| North America | 11.8% CAGR (projected) | Driven by technological advancements and drone adoption |

| Asia Pacific | 13.5% CAGR (projected) | Growth in industrial and commercial drone applications |

| Inner Rotor Segment | 60.9% market share | Higher power density, compact design |

| Power Output < 750W | 50.1% revenue share | Long operating life, lower maintenance, high voltage tolerance |

Brushless motors require electronic speed controllers (ESCs) for operation. While this increases initial costs, the benefits—such as longer lifespan, higher efficiency, and reduced noise—offset the investment over time. These motors also generate less heat and experience minimal wear, making them the preferred choice for most Drone Motors in advanced drones.

Brushed Motors

Brushed motors use brushes and a commutator to transfer electrical current. This design creates friction, leading to wear and heat buildup. Brushed motors typically appear in toy drones, entry-level models, and applications where cost is a primary concern.

- Brushed motors have a lower initial cost and simpler control requirements.

- They require regular maintenance due to brush wear, which can limit their operational lifespan.

- Friction from the brushes causes energy loss and periodic replacement, usually every two to seven years depending on usage.

A cost-benefit analysis shows that while brushed motors are cheaper upfront, they incur higher maintenance costs and have shorter lifespans. The following table compares key factors:

| Factor | Brushed Motor | Brushless Motor |

|---|---|---|

| Initial Cost | Low | Higher (due to electronics) |

| Lifetime | Short (brush wear) | Long (no brushes to wear) |

| Efficiency | Medium | High |

| Maintenance | Higher (brush replacement) | Lower (no brush wear) |

| Noise | Higher (mechanical friction) | Lower (controlled current switching) |

Brushed motors remain suitable for applications with limited run time or where noise and efficiency are less critical.

Other Motor Types

Some specialized drones use alternative motor types, such as coreless DC motors or stepper motors. Coreless motors offer lightweight construction and fast response, making them suitable for micro drones and small quadcopters. Stepper motors, while uncommon in flight applications, may appear in gimbal systems or camera stabilization units due to their precise positioning capabilities.

Tip: Always match the motor type to the drone’s intended use. For example, heavy-lift drones and professional camera platforms benefit from the efficiency and durability of brushless motors, while toy drones can use brushed or coreless motors to keep costs low.

Why Choose Brushless Motors

Efficiency

Brushless motors set the standard for efficiency in modern drones. Engineers design these motors to minimize energy loss, which means more power reaches the propellers and less turns into heat. Experimental studies show that brushless motors can achieve efficiency rates up to 90%, while brushed motors often reach only about 50%. For example, one study tested a brushless motor with 2S (7.4V) and 3S (11.1V) batteries. The results showed a maximum thrust of 638.5g at 108.9W with the 3S battery, far surpassing the performance of brushed models under similar conditions. This high efficiency allows drones to fly longer on a single charge, making brushless motors the preferred choice for applications where flight time and energy conservation matter.

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Efficiency | Approximately 50% | Up to 90% |

| Maintenance | Frequent (brush wear) | Minimal |

| Noise | High | Low (quieter) |

| Lifespan | Short | Long |

| Control | Basic | Precise (electronic) |

| Application | Toys, basic drones | Hobby, professional, industrial |

Note: High efficiency in brushless motors means less wasted energy, which translates to longer flights and better performance for Drone Motors in both hobby and professional drones.

Durability

Durability stands out as a major advantage of brushless motors. These motors do not use brushes or commutators, which are common sources of friction and wear in brushed motors. As a result, brushless motors last much longer and require less maintenance. Measured current consumption under heavy load shows that brushless motors draw only 11.5A, compared to 27.4A for brushed motors. This lower current means less heat and less stress on the motor components. Reduced heat generation helps prevent damage to both the motor and nearby electronics, increasing the overall lifespan of the drone.

| Performance Metric | Brushless Motors (BLDC) | Brushed Motors |

|---|---|---|

| Service Life | Exceeds 20,000 hours (only shaft bearings wear) | Typically 2,000 – 4,000 hours (brush wear) |

| Efficiency | 2-3 times higher efficiency | Lower efficiency due to friction and brush losses |

| Speed Control Precision | Within 1-2% (high-end BLDC) | About 10% |

| Heat Generation | Lower heat due to better thermal path and less friction | Higher heat due to brush friction and poor heat dissipation |

| Maintenance Needs | Minimal (no brushes to replace) | Regular brush replacement and commutator maintenance |

| Reliability Factors | No arcing, reduced EMI, better for harsh environments | Arcing causes EMI and wear, less reliable |

Brushless motors also provide more consistent speed control, with precision within 1-2%, compared to about 10% for brushed motors. This stability improves reliability, especially in demanding environments such as industrial inspections or long-range mapping missions.

Performance

Performance defines the difference between brushless and brushed motors in real-world drone use. Brushless motors deliver higher thrust, smoother acceleration, and more precise control. Pilots notice these benefits in racing drones, where quick response and stable handling are essential. Aerial photographers rely on the smooth operation of brushless motors to capture sharp, blur-free images and video. Industrial users benefit from the consistent power output and reliability, which support heavy-lift operations and long-duration flights.

Tip: Brushless motors help drones handle sudden changes in direction or speed without losing stability. This makes them ideal for freestyle flying, racing, and professional filming.

Brushless motors also support advanced features such as electronic speed controllers (ESCs), which allow for fine-tuned adjustments and automated flight modes. These capabilities enable Drone Motors to meet the needs of both hobbyists and professionals, from simple quadcopters to complex commercial platforms.

Motor Selection Factors

Size and Weight

Motor size and weight play a critical role in drone performance. Manufacturers typically specify motor size using a four-digit code. The first two digits indicate the stator diameter in millimeters, and the last two show the stator height. Larger stators generate more torque and support bigger propellers, which increases thrust. Smaller motors weigh less and respond quickly but produce less power. Selecting the right motor involves balancing size and weight to achieve optimal thrust, efficiency, and flight characteristics.

| Frame Size | Prop Size | Motor Size Range |

|---|---|---|

| 150mm or smaller | 3″ or less | 1105 – 1306 or smaller |

| 180mm | 4″ | 1806, 2204 |

| 210mm | 5″ | 2205-2208, 2305-2306 |

| 250mm | 6″ | 2206-2208, 2306 |

| 350mm | 7″ | 2506-2508 |

| 450mm and larger | 8″ or more | 26XX and larger |

Heavier motors add to the drone’s total weight, which can reduce flight time and agility. Lighter motors improve maneuverability but may limit payload capacity.

KV Rating

The KV rating defines how many revolutions per minute (RPM) a motor produces for each volt supplied. The formula RPM = KV × Voltage helps calculate the theoretical no-load speed. High KV motors spin faster but deliver less torque, making them suitable for lightweight racing drones. Low KV motors provide more torque and thrust, which benefits heavy-lift drones. Technical studies show that power output depends on both torque and speed, and power consumption rises quickly as speed increases. Engineers use advanced testing methods, such as vibration analysis, to ensure motors operate within safe limits.

Tip: Always match the KV rating to the drone’s voltage and intended use. High KV for speed, low KV for lifting power.

Torque and Thrust

Torque and thrust determine how well a drone can lift and maneuver. Motors with more magnetic poles produce higher torque but lower speed. Fewer poles result in higher speed but less torque. For example, a 4-pole motor generates twice the torque of a 2-pole motor at the same power. The number of coil turns also affects performance. More turns lower the KV rating and increase torque, while fewer turns raise the KV and speed. Selecting the right balance ensures the drone can handle its intended tasks.

| Parameter | Effect/Relationship | Impact on Performance |

|---|---|---|

| Magnetic Poles | More poles = higher torque, lower speed | Suits large props, heavy lifting |

| Coil Turns | More turns = lower KV, higher torque | Better for high-torque applications |

| Example | 21T motor = lower KV, more torque; 9T motor = higher KV, more speed | Matches motor to propeller and task |

Propeller Compatibility

Propeller size and pitch must match the motor’s torque and power output. Larger propellers generate more thrust but require more torque and power. Smaller propellers work efficiently at high speeds but need less torque. The thrust-to-power ratio measures how effectively a motor converts electrical power into thrust. A higher ratio means better efficiency and longer flight times. Proper matching of motor and propeller ensures stable flight and optimal energy use.

Selecting the right motor and propeller combination improves flight performance, efficiency, and reliability.

Choosing Drone Motors

Application Types

Selecting the right motor starts with understanding the drone’s intended use. Different applications demand specific motor characteristics. Racing drones need high-speed motors with rapid acceleration. Freestyle drones benefit from responsive motors that handle quick maneuvers. Heavy-lift drones, such as those used in agriculture or logistics, require motors with high torque and thrust to carry large payloads. Commercial drones for mapping or inspection prioritize efficiency and reliability for longer missions.

Tip: Always match the motor’s capabilities to the drone’s mission profile. For example, a photography drone needs smooth, quiet motors to minimize vibration, while a racing drone needs lightweight, high-KV motors for speed.

Performance Needs

Performance requirement analyses help ensure the chosen motor meets the drone’s operational demands. The following steps outline a structured approach:

- Define the drone’s mission profile, including flight time, speed, and endurance.

- Calculate the necessary thrust based on maximum takeoff weight and mission needs.

- Review propeller datasheets to determine required RPM and torque.

- Select a motor that balances power, efficiency, and weight.

- Evaluate robustness and reliability for the operating environment.

- Confirm the thermal design supports adequate cooling.

- Check for certifications if regulatory compliance is required.

Balancing motor size, KV rating, and propeller compatibility optimizes performance. For example, a thrust-to-weight ratio of at least 2:1 ensures stable flight and maneuverability. Matching the motor’s KV rating with the battery voltage and propeller size further refines efficiency.

Recent technological advancements continue to shape the future of Drone Motors. Market research forecasts highlight innovations such as AI-driven motor optimization, lightweight composite materials, and improved battery technologies that extend flight times. Modular designs and smart sensors now enable real-time monitoring and predictive maintenance, supporting longer drone lifespans and safer operations.

Brushless motors remain the standard for most drones due to their high efficiency, long lifespan, and precise control. The table below highlights key performance factors:

| Feature | Value/Description |

|---|---|

| Rotational Speed | 12,000+ RPM |

| Control Precision | 1°–5° with advanced algorithms |

| Efficiency | High, with minimal noise and wear |

| Cost | Medium, offset by durability and stability |

Recent market studies show that matching motor specifications to the drone’s purpose and the latest technology trends ensures optimal performance. When selecting a motor, users should:

- Define the drone’s main application.

- Check required thrust and power.

- Match motor size, KV rating, and propeller.

- Consider new lightweight and smart motor designs.

Always align motor choice with both mission needs and evolving industry innovations.