You can achieve drone fly using dc motor technology, but your choice of motor type matters. Brushless motors dominate the drone market because they deliver higher efficiency, longer life, and lower maintenance than brushed motors. Industry data shows brushless motors account for nearly 67% of the global dc motor market, excelling in power-to-weight ratio and reliability—key factors for any drone motor. Brushed motors appear mostly in small toy drones, while advanced drone fly depends on the performance and precision that brushless motors provide.

Key Takeaways

- Brushless DC motors offer the best efficiency, power, and low maintenance for most drones, making them ideal for longer flights and heavier payloads.

- Brushed and coreless brushed motors suit small or toy drones but need more maintenance and have shorter lifespans.

- Choose drone motors by matching thrust, power, and propeller size to your drone’s weight and purpose for stable and safe flight.

- Assemble your drone carefully using quality parts and follow step-by-step instructions to ensure reliable performance and safety.

- Regularly inspect, clean, and maintain your drone motors to prevent failures and replace them promptly if you notice damage or unusual behavior.

DC Motor Types

When you build or upgrade a drone, you need to understand the differences between brushed, brushless, and coreless brushed motors. Each type of motor offers unique advantages and limitations for drone applications.

Brushed DC Motor

Brushed DC motors use physical brushes and a commutator to switch current in the rotor. You often find these motors in entry-level or toy drones because they are simple and inexpensive. However, they have several drawbacks for drone use:

- Brushed motors generate more friction and heat due to the contact between brushes and the commutator.

- They produce significant electrical and acoustic noise, which can interfere with sensitive drone electronics.

- The brushes wear out over time, so you need to replace them frequently.

- Brushed motors have lower efficiency and slower acceleration compared to other types.

Tip: If you want a low-cost drone for basic flying, a brushed DC motor can work. For longer life and better performance, you should consider other options.

Brushless DC Motor

Brushless motors have become the standard for most drone motor applications. These motors use electronic commutation instead of physical brushes, which brings several key benefits:

- Brushless motors deliver higher efficiency and convert more electrical energy into thrust, giving your drone longer flight times.

- They operate with less friction, so you get less heat and quieter performance.

- Brushless motors provide greater torque, speed, and precise control, which is essential for stable flight and advanced maneuvers.

- You do not need to worry about brush wear, so maintenance is minimal and lifespan is much longer.

- Professional drones for aerial photography, mapping, and delivery almost always use brushless DC motors because they support heavy payloads and demanding tasks.

| Feature | Brushed Motor | Brushless Motor |

|---|---|---|

| Efficiency | Lower (~50%) | Higher (up to 90%) |

| Maintenance | Frequent (brush wear) | Minimal |

| Noise | High (electrical & acoustic) | Low (quieter) |

| Lifespan | Short | Long |

| Control | Basic | Precise (electronic) |

| Application | Toys, basic drones | Hobby, pro, industrial |

Note: You should choose a brushless motor if you want your drone to fly longer, carry more weight, and perform reliably. Brushless DC motors dominate the market for these reasons.

Coreless Brushed Motor

Coreless brushed motors use an ironless rotor, which makes them lighter and more responsive than traditional brushed motors. You will see these motors in small toy drones and other weight-sensitive devices. Here are some important points:

- The coreless design reduces inertia, so your drone can accelerate and change direction quickly.

- These motors offer higher power density and efficiency (often over 80%) compared to standard brushed motors.

- Coreless brushed motors are easy to control and work well with simple electronics.

- They are ideal for small drones where every gram counts, but they are sensitive to high speeds and can be more expensive.

- Lifespan depends on bearing quality, but they still require maintenance due to brushes.

Tip: If you want a lightweight, agile drone for indoor flying or as a toy, a coreless brushed motor is a strong choice. For larger or more advanced drones, brushless motors remain the best option.

Comparison at a Glance

- Brushless motors give you the best efficiency, power, and reliability for most drone applications.

- Brushed motors are suitable for basic, low-cost drones but need frequent maintenance.

- Coreless brushed motors excel in small, lightweight drones where quick response and low weight matter most.

Make a Drone Using DC Motor

Essential Parts

To make a drone that flies reliably, you need to gather high-quality components. Each part plays a critical role in the drone’s performance and safety. Here is a list of the essential parts you will need:

- Motors (4 or more): Choose motors that match your drone’s size and weight. Brushless motors work best for most builds, but coreless brushed motors suit small, lightweight models.

- Propellers: Select propellers that fit your motors and frame. The right propeller size ensures stable lift and efficient flight.

- Electronic Speed Controllers (ESCs): These devices regulate the speed of each motor. You need one ESC for each motor.

- Flight Controller: This is the brain of your drone. It stabilizes flight and processes signals from your remote control.

- Frame: The frame holds all components together. Use lightweight materials like carbon fiber or plastic for better performance.

- Battery: Most drones use lithium polymer batteries for their high energy density and light weight. Make sure the battery matches your power needs and fits your frame.

- Remote Control and Receiver: These allow you to control the drone from a distance.

- Wiring and Connectors: Secure connections ensure reliable power delivery and signal transmission.

- Landing Gear: Protects the drone during takeoff and landing.

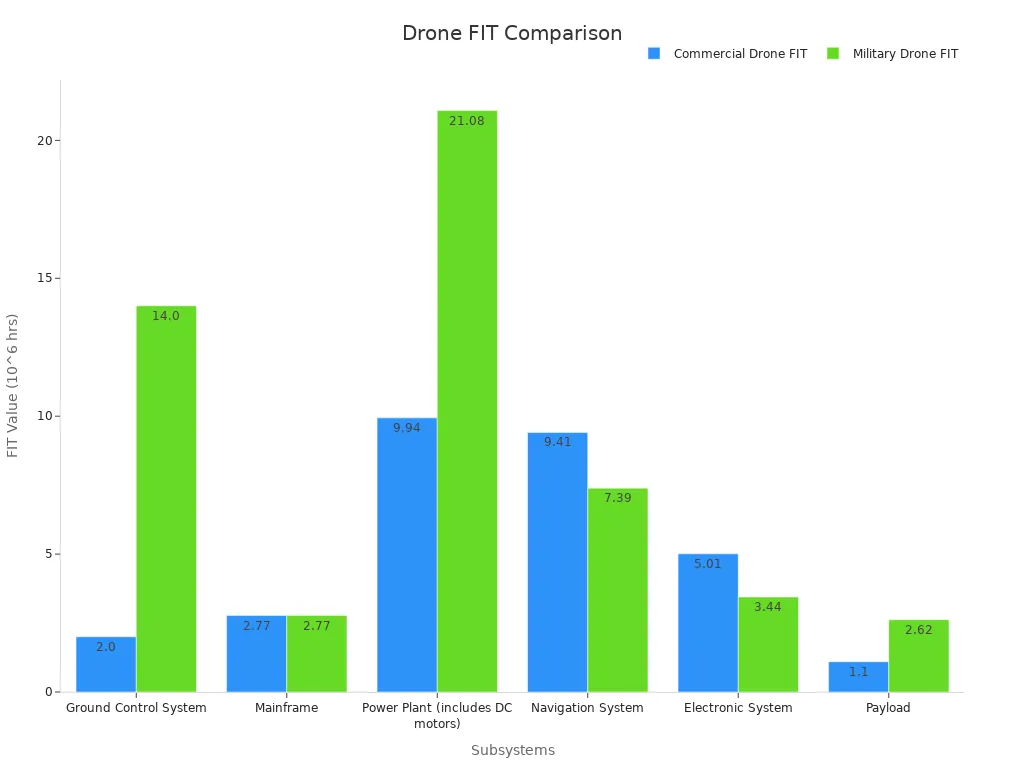

Tip: Always select reliable components. The power plant, which includes the motors, has the highest failure rate among drone subsystems. Reliability data shows that the power plant accounts for 32.88% of failures in commercial drones. Use the table below to compare subsystem reliability and plan your maintenance schedule.

| Subsystem | Commercial Drone FIT (Failures per 10^6 hrs) | Commercial Drone MTBF (hours) | Commercial Drone Incidence (%) |

|---|---|---|---|

| Ground Control System | 2.00 | 500,000 | 6.62 |

| Mainframe | 2.77 | 360,985 | 9.16 |

| Power Plant (includes motors) | 9.94 | 100,604 | 32.88 |

| Navigation System | 9.41 | 106,270 | 31.13 |

| Electronic System | 5.01 | 199,601 | 16.57 |

| Payload | 1.10 | 909,091 | 3.64 |

Assembly Steps

Building your drone requires careful assembly and attention to detail. Follow these steps to ensure a safe and functional build:

- Prepare the Frame: Lay out the frame on a clean surface. Attach landing gear if needed.

- Mount the Motors: Secure each motor to the designated arms of the frame. Make sure the orientation matches the flight controller’s configuration.

- Install the Electronic Speed Controllers: Attach one ESC to each motor. Route the wires neatly to avoid tangling.

- Connect the Flight Controller: Mount the flight controller at the center of the frame. Connect the ESC signal wires to the correct ports on the flight controller.

- Attach the Propellers: Fix the propellers to the motors. Check that each propeller matches the correct rotation direction for stable drone fly.

- Install the Battery: Place the battery in a secure compartment. Use straps or holders to prevent movement during flight.

- Connect the Remote Receiver: Link the receiver to the flight controller. Test the connection with your remote control.

- Check All Wiring: Inspect every connection. Ensure that wires are tight and insulated to prevent short circuits.

- Balance the Drone: Adjust the position of the battery and other components to keep the drone level.

Note: Use RAMS (Reliability, Availability, Maintainability, and Safety) principles during assembly. This approach helps you select the best components and design a safer, more reliable drone.

Initial Testing

Before your first flight, you must test the drone to confirm that every system works as intended. A structured testing process reduces the risk of failure and improves safety.

- Verification Preparation: Review your assembly against approved plans. Use calibrated tools to check each motor, propeller, and controller.

- Component Testing: Power up the drone without propellers. Test each motor and ESC for correct response using the flight controller.

- System Integration: Attach the propellers. Run the motors at low speed to check for vibration or imbalance.

- End-to-End Testing: Simulate real flight scenarios. Test all flight modes and mission phases using your remote control and flight controller.

- Data Collection: Record motor temperatures, battery voltage, and flight controller logs. Use this data to assess performance and identify issues.

⚠️ Safety Alert: Always test your drone in an open area, away from people and obstacles. Wear safety glasses and keep your hands clear of spinning propellers.

A thorough initial test ensures that your drone motor, propeller, battery, and controllers work together smoothly. This process helps you achieve stable and reliable drone fly from your very first launch.

Drone Motor Selection

Thrust and Power

Selecting the right drone motor starts with understanding thrust and power requirements. You must match the total thrust from all motors to the drone’s weight, ensuring stable lift and maneuverability. For reliable flight, aim for a thrust-to-weight ratio of at least 2:1. This means your motors should produce twice the thrust of your drone’s total weight.

When you evaluate motor thrust and power, consider these factors:

- Motor current ratings: Never exceed the continuous current limit to avoid burnout.

- No-load current and voltage: These help you estimate internal resistance and efficiency.

- Motor efficiency: Higher efficiency means more electrical power turns into thrust.

- Thrust-to-power ratio: This shows how well your motor and propeller convert power into lift.

- Internal resistance: Lower resistance improves efficiency and reduces heat.

- Propeller compatibility: Always match propeller size and pitch to your motor’s specifications.

- Motor weight: Lighter motors improve flight time and agility.

- Number of magnetic poles and coil turns: These affect torque and speed.

You can calculate the required power using the formula: Power = Thrust × Voltage / Efficiency. For example, a drone needing 20 N of thrust with 90% efficiency and 14.8 V battery requires about 296 W of power. Always ensure your battery can supply enough current for all motors.

KV Rating and Propeller Size

The KV rating tells you how many revolutions per minute (RPM) your motor spins per volt. High KV motors spin faster but offer less torque, making them ideal for lightweight racing drones with small, high-pitch propellers. Low KV motors spin slower but provide more torque, which suits heavy drones with large propellers.

Empirical studies show that ultralight drones use motors with 2300-3000 KV and 5-inch propellers. Freestyle drones use 1500-2500 KV motors with 6-7 inch propellers. Long-range drones need 980-1900 KV motors and propellers 7 inches or larger. Matching KV rating and propeller size to your drone’s weight and purpose ensures optimal thrust and power without overloading the motor.

Compatibility and Safety

You must ensure all components work together for safe and reliable operation. The flight controller should support your chosen motor and ESCs. Always check that the propeller size matches the motor’s torque and RPM limits. Use motors with proven reliability and avoid exceeding current or voltage ratings.

⚠️ Safety Tip: Test your drone motor setup in a controlled environment. Monitor motor temperature and listen for unusual sounds. Replace any motor that shows signs of wear or overheating.

Choosing the right motor, propeller, and flight controller combination gives you stable thrust, efficient power use, and long-lasting performance.

Drone Motor Care

Maintenance Tips

Proper care extends the life of your drone motor and keeps your flights safe. You should follow a regular maintenance routine for both brushed and brushless motors:

1. Clean the motor and surrounding area to remove dirt, dust, and debris. This prevents buildup that can impair performance. 2. Inspect the motor for visible wear, cracks, frayed wires, or loose connections. Early detection helps you avoid sudden failures. 3. Lubricate moving parts such as bearings and gears. This reduces friction and wear, especially in brushed motors. 4. Replace worn parts like bearings, shafts, or brushes. This step is crucial for brushed motors, which experience more wear. 5. Check all electrical connections. Tighten any loose wires and remove corrosion to ensure reliable power delivery. 6. Adjust motor controller settings if you notice irregular performance. 7. Test the motor after every maintenance session to confirm smooth operation. 8. Store your motor in a dry, cool place to prevent moisture damage.

Manufacturers use accelerated life testing and Weibull analysis to predict motor lifespan. These methods help you set maintenance schedules and choose reliable motors for your drone.

Troubleshooting

You may encounter issues with your drone motor during pre-flight checks or in the air. Use this table to identify and resolve common problems:

| Troubleshooting Data / Replacement Indicator | Explanation / Relevance to Motor Care |

|---|---|

| Visible damage inspection | Look for cracks or wear on motors and propellers to spot issues early |

| Cracked or worn propellers | Replace immediately to maintain motor efficiency and flight stability |

| Pre-flight motor and propeller checks | Routine inspections catch problems before they cause failure |

| Cleaning motors and propellers | Prevents dirt buildup that strains the motor |

| Sensor recalibration and reset procedures | Ensures motor sensors work correctly for stable flight |

| Warning signals and indicators | Pay attention to alerts that may signal motor malfunction |

| Professional repairs for complex issues | Seek expert help if basic troubleshooting does not fix the motor |

Tip: Always listen for unusual sounds and monitor motor temperature during operation.

When to Replace

You should replace your drone motor if you notice any of these signs:

- Persistent overheating or burning smell during operation

- Unusual noises, vibrations, or reduced thrust

- Visible damage such as cracks, bent shafts, or melted insulation

- Frequent loss of power or erratic speed changes

- Worn brushes in brushed motors or excessive bearing play in brushless motors

Timely replacement ensures your drone remains safe and reliable in the air.

You can achieve reliable drone fly by choosing the right motor for your needs. Brushless motors deliver high efficiency, low maintenance, and strong power-to-weight ratios, making them ideal for most drone fly scenarios. To maximize performance and safety, follow these best practices:

- Select motors based on payload, flight time, and propeller compatibility.

- Inspect motors for wear or debris before each use.

- Operate motors within safe temperature ranges and avoid water or dust exposure.

Consistent care and smart choices help your drone motor last longer and perform at its best.